6. Braking System

The machines are equipped with an electro-magnetic brake that

ensure stopping all moving parts within 10 seconds,

The brake pads of the braking system are subject to wear, it

is recommended that they are checked regularly and replaced

when necessary, to maintain the braking time within regulations

fixed by the norms.

6.1 MAINTENANCE AND ADJUSTMENT OF

THE BRAKING SYSTEM

REPLACING THE BRAKE LININGS

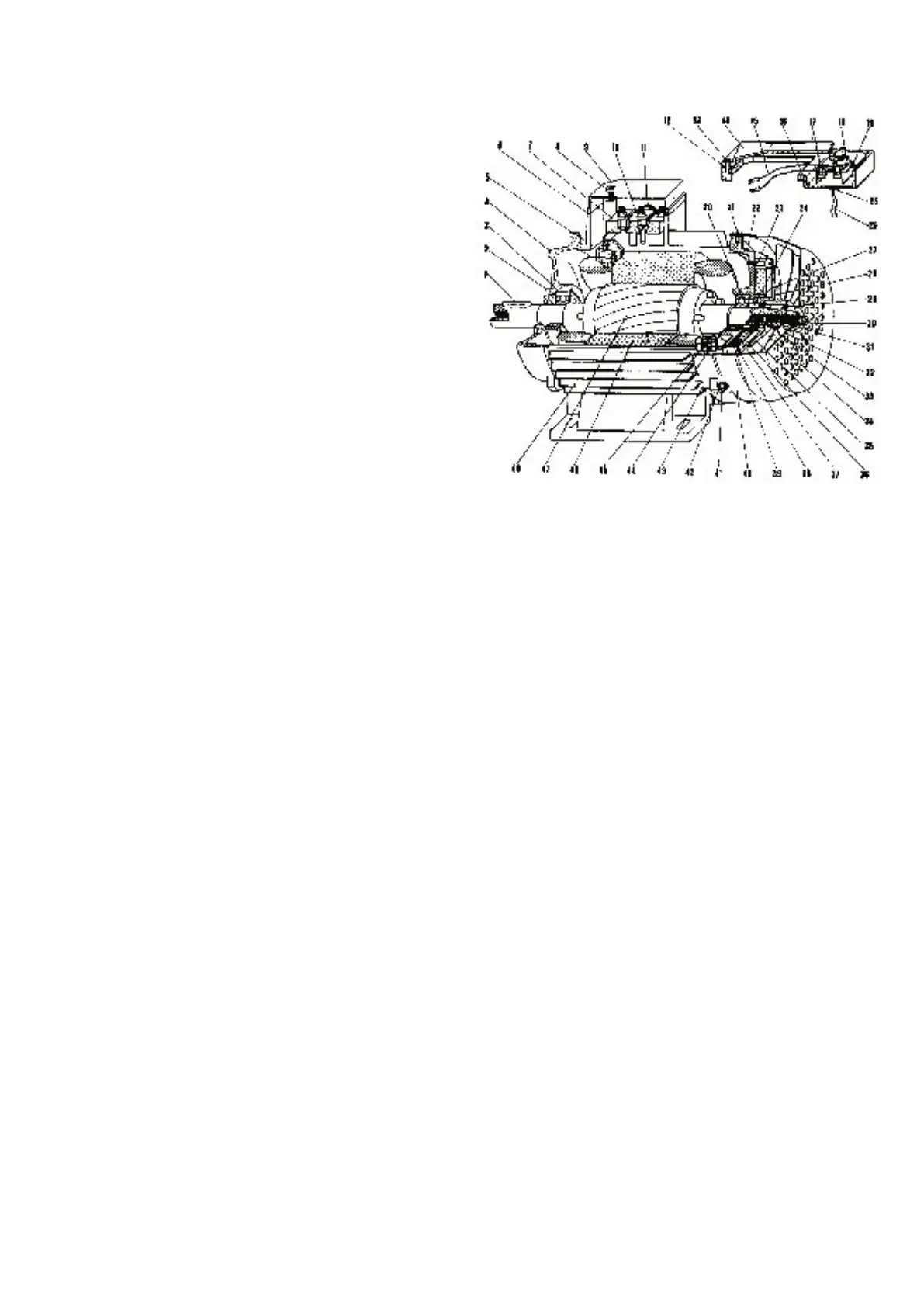

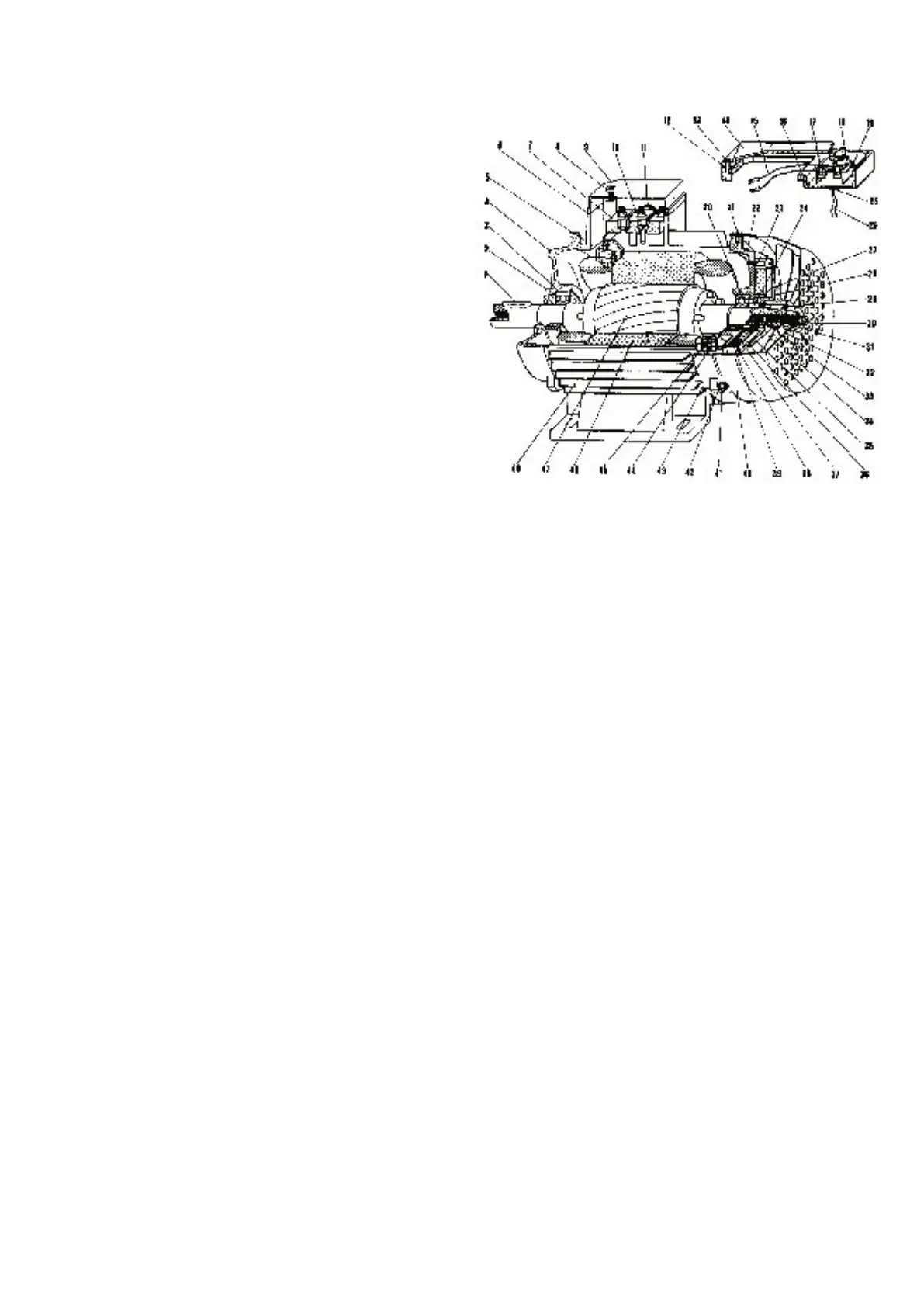

Remove the fan cover (

40) and unscrew the self-locking nut

(31), pull out thecooling and braking fan (34) On the mobile

anchor (

28) of the brake you will find the lining. Pull the old lining

off and, with clean hands, glue the new one on. To re-assembly

the parts, please follow directions in reversed order and type of

operations.

BRAKE UNIT REPLACEMENT

Take the fan cover (

40) off and unscrew the self locking nut (31)

pull out the cooling and braking fan (

34), the thrust linings (24)

and the thrust spring (

27). At this point, you should isolate the

rectifier diode by disconnecting the cables (the diode can be

found either in position (

44) or in the terminal box position 18).

Unscrew the 3 allen screws (

23), change the brake unit and

repeat the operations in reverse to fit the other parts.

ADJUSTMENT OF THE BRAKING AIR-GAP

The machine will stop between 6 and 10 seconds maximum. By

turning the self locking nut of the brake control (

31) it is possible

to vary the braking time from 6 to 10 seconds. It is extremely

important that after this operation a gap of 0.5 mm remains

between the mobile anchor and the brake unit. The air gap is the

distance between the mobile anchor and the brake unit.

MANUAL OPERATION TO RELEASE THE BRAKE

Unscrew the self locking nut (

31) until the cast iron fan moves

away from the mobile anchor (

28) beyond the widest possible

air gap. This allen screw also allows to check the air gap back to

the original distance after the wearing out of the brake linings.

Loading...

Loading...