5. Safety Advice

a) Machine out of order

Before making any adjustments or repairs to the machine, disconnect from the electrical supply.

If any faults are suspected, disconnect the electrical supply and put a visible notice on the machine.

b) Before operating

• Keep the surrounding floor space clean;

• Wear suitable clothing, not loose garments;

• Check that the blade is sharp, correctly tensioned, the correct width, and correctly positioned on the flywheels;

• Use support stands for long or wide material

• Use a dust extractor.

c) During operation

Never clean the table with hands, use a brush or a piece of wood.

In case of an emergency such as blade breakage or other emergency do not attempt to intervene before the bandwheels have

completely stopped.

When the has stopped, lower the upper blade guides to the level of the table, loosen the blade and leave a sign advising of this

operation. REMOVE THE ELECTRICAL CONNECTION PLUG.

d) During maintenance

• Place the machine out of order as indicated above;

• Use gloves to handle the blade;

• Periodically check the electrical grounding of the machine.

5.1 SAFETY DEVICES AND GUARDS

The upward portion of the blade is fully protected inside the machine column.

The down ward portion of the blade is protected by a fixed guard, integral with the blade-guide which is adjustable for height

depending on the thickness of material to be cut.

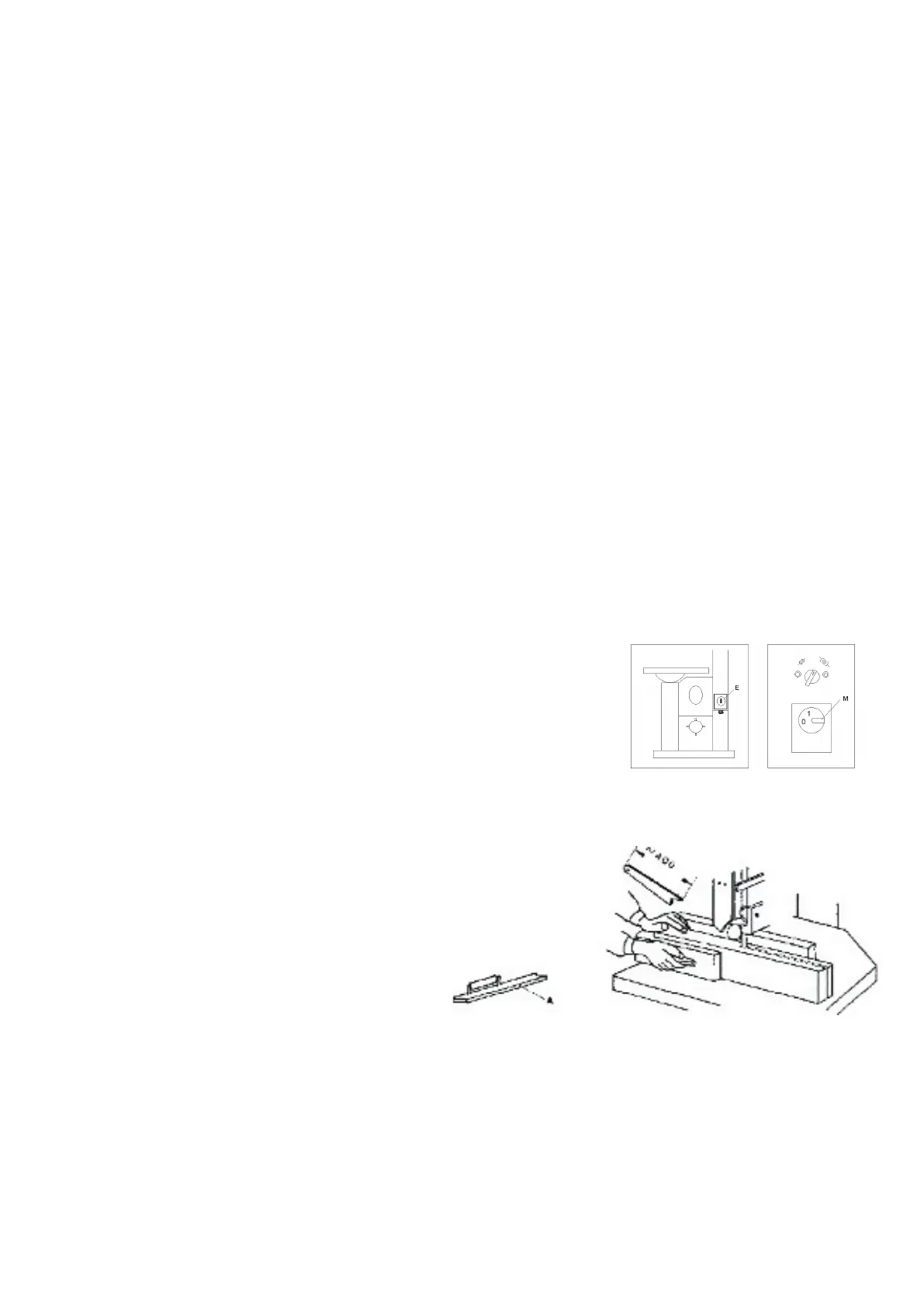

5.2 FACE CUTTING

Use a square for safe guiding of the work during face cutting FIG. 5.1

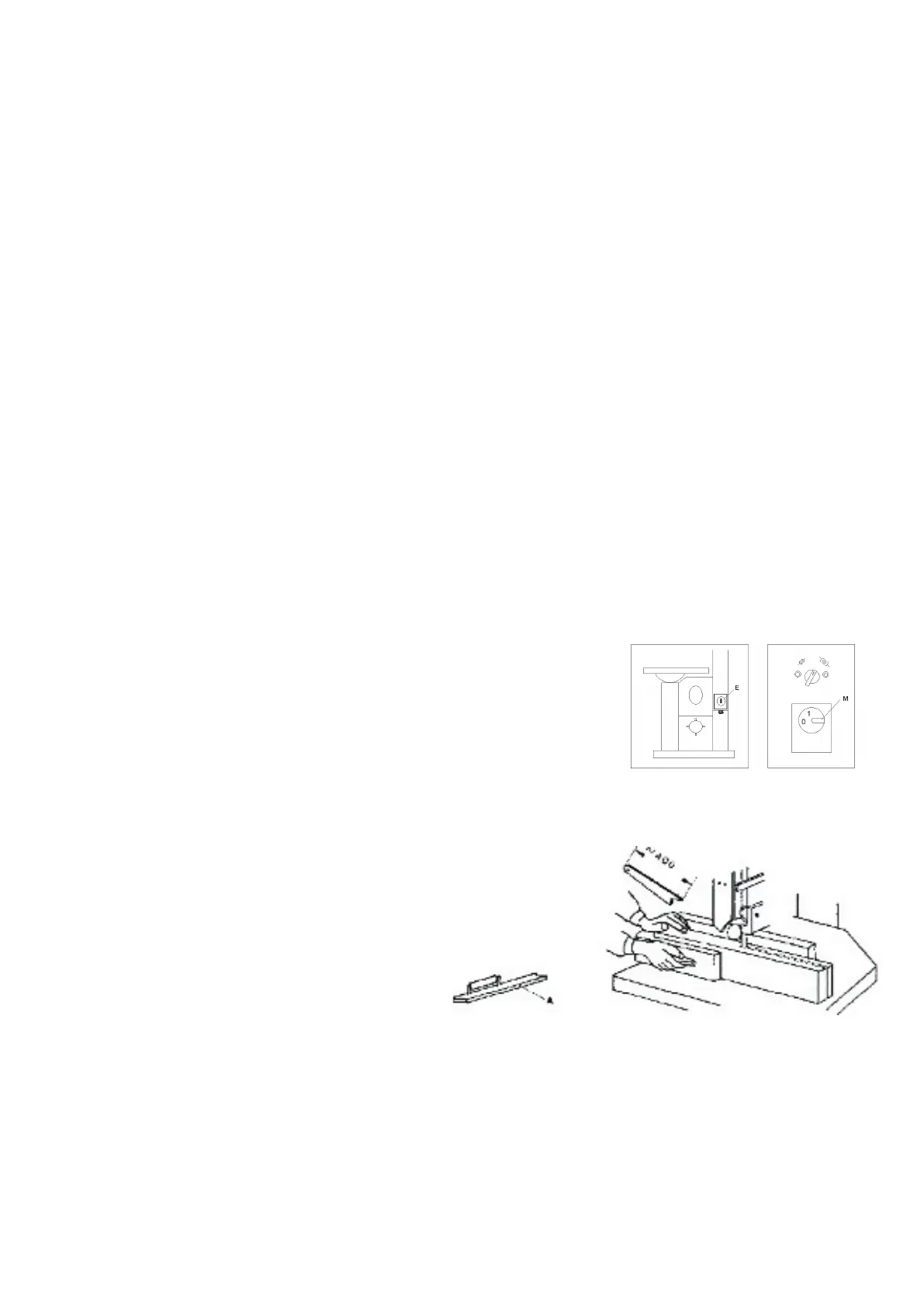

CUTTING SHORT PIECES FIG. 5.2

Use pushing devices for cutting of short pieces.

The pushing device type A is recommended for narrow pieces.

FIG. 5.1

FIG. 5.2

Loading...

Loading...