Maintenance Manual STEMME S10

Date of Issue: Oct. 1, 1990 page: 24

Amendment No.: 18 Date: Oct. 15, 2012

A4010021_B19.doc

Doc.No.: A40-10-021

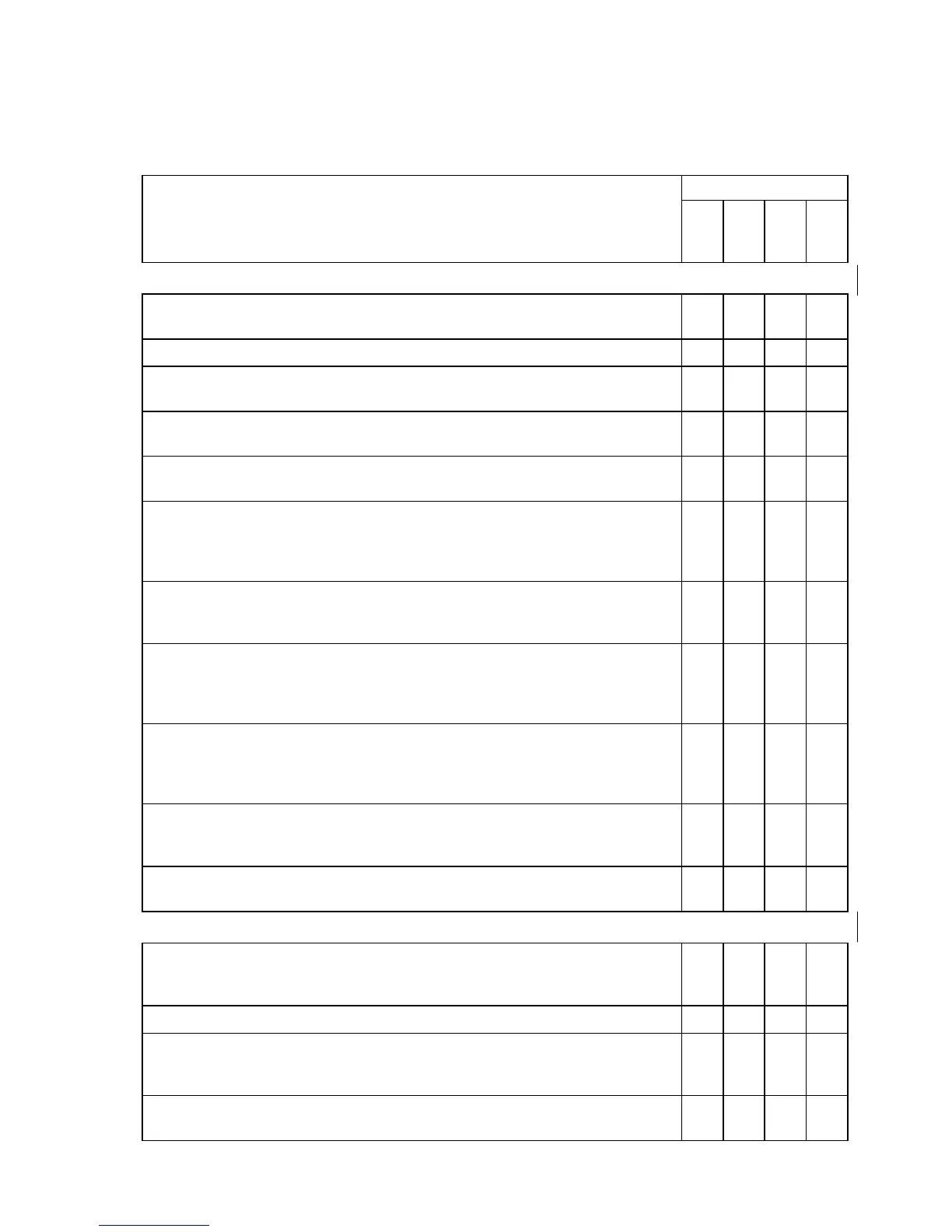

Check Lists for Periodical Inspections

Caution: Prior to any rigging tasks, please refer to chapter "Maintenance Instructions".

Inspection Type

Type and Subject of Inspection

Type 1a

Type 2

Type 3

5.3.1 Wing

1.

Check surface for damage and cracks, look out for signs of hidden structural

damage, check registration marks, renew if necessary.

X X

2.

Check drain and vent outlets. X

3.

At the wing root: inspect quick-release joints for function and proper sealing,

check plug-in connector of fuel gauge.

X X

4.

Inspect fuel tank unit for: function of tank ventilation, proper sealing of filler

caps, leakage of fuel into the tank compartment of the wing.

X X X

5.

Inspect wing fittings, grease slightly, check play, check locks of wing

attachment bolts

X X X

6.

Check wing flap and aileron bearings for correct play, function and corrosion,

clearances of the components between each other and spanwise clearance

between the components and the wing 3 ± 0.5 mm. Check upper and lower

gap sealings.

X

7.

Check all control rods and bearings in the area of the wing-to-central-fuselage

attachment; check quik release joints -

is a spring cotter fastened unloosable to

Check and maintain the L´Hotellier quik release joints of the aileron push-pull

rods at the inner-to-outer wing attachements, according to the manufacturer

instructions (ref. to Appendix A). Is a spring cotter fastened unloosable to the

connector

X X X

9.

Remove fairings on the flap and aileron link rods and inspect the bellcrank

levers and the other parts of the flap and aileron drive systems in the wing for

tight fit of all screw joints, cracks, deformation and other defects. Use an

endoscope or an inspection mirror.

X X

10.

Examine all control rods in the terminal swaging area for embrittlement or

crack initiation (axial and peripherical direction), check fork terminals for

cracks, particulary the fork terminals where the root turns into the webs.

X X

11.

Inspect air brakes for correct retracted position and ease of operation, check

screw joints for tight fit.

X X

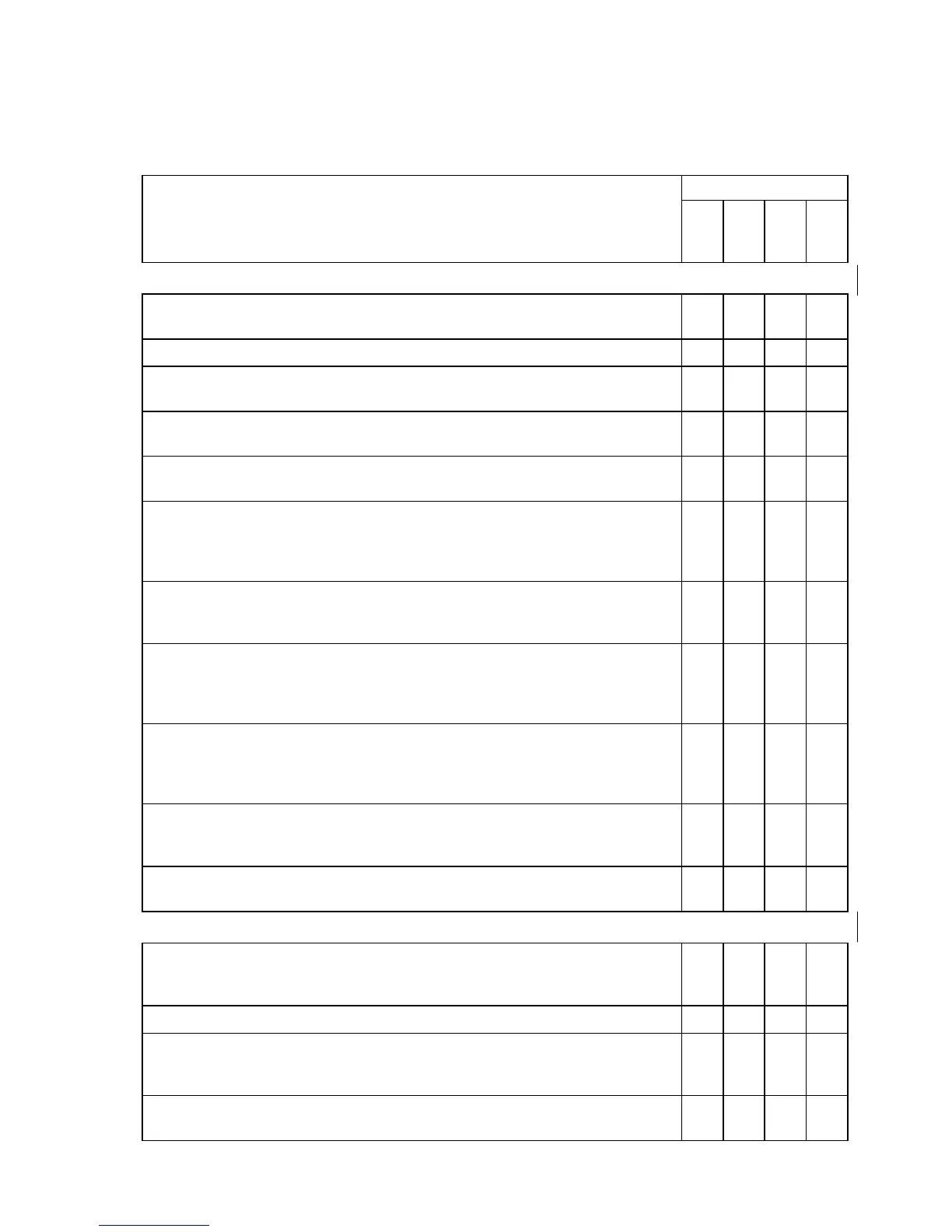

5.3.2 Fuselage Front Section

1.

Inspect surface for damage and cracks, look out for signs of hidden structural

damage; check especially fuselage lower surface for damage caused by stone

strike.

X X

2.

Check static pressure ports. X X X

3.

Propeller dome lock: check for proper function, particularly safe locking during

engine operation. Only with the lever fully engaged, the switch installed in the

locking system completes the starter circuit.

X X X X

4.

Check condition of propeller dome push tube; play perpendicular to the flight

direction must be less than 3 mm (at the dome tip)

X X

Loading...

Loading...