INSTALLATION

Preparation

ENGLISH

www.stiebel-eltron.com

DHB-E LCD | 8

Pipe assembly for DHB water plug-in couplings

Use the water plug-in couplings if the existing installation contains

water plug-in connections from a DHB water heater.

Load shedding relay (LR 1-A)

The load shedding relay for installation in the distribution board

provides priority control for the instantaneous water heater when

other appliances, suchas electric storage heaters, are being op-

erated simultaneously.

Central thermostatic valve (ZTA 3/4)

Use the thermostatic valve for central premixing when, forex-

ample, operating an instantaneous water heater with preheated

water. For use in shower operation, the valve must be set to a

maximum of 55°C.

9. Preparation

9.1 Installation location

!

Material losses

Install the appliance in a room free from the risk of frost.

f Always install the appliance vertically and near the draw-off

point. For horizontal installation, see chapter "Alternative in-

stallation methods/ Horizontal installation of the appliance".

The appliance is suitable for undersink and oversink installation.

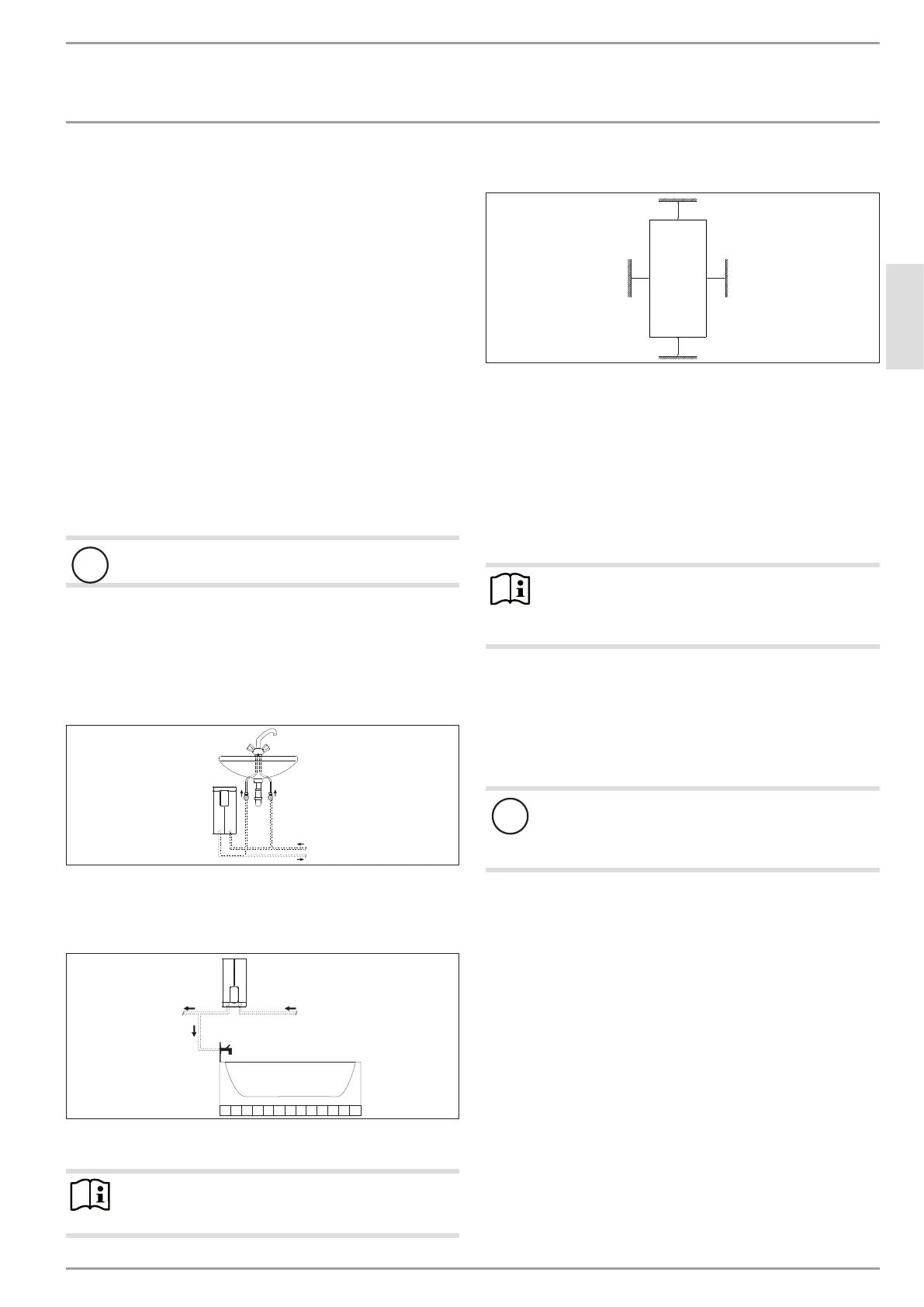

Undersink installation

D0000056242

1

2

1 Cold water inlet

2 DHW outlet

Oversink installation

D0000057030

12

1 Cold water inlet

2 DHW outlet

Note

f Mount the appliance on the wall. The wall must have

sufficient load bearing capacity.

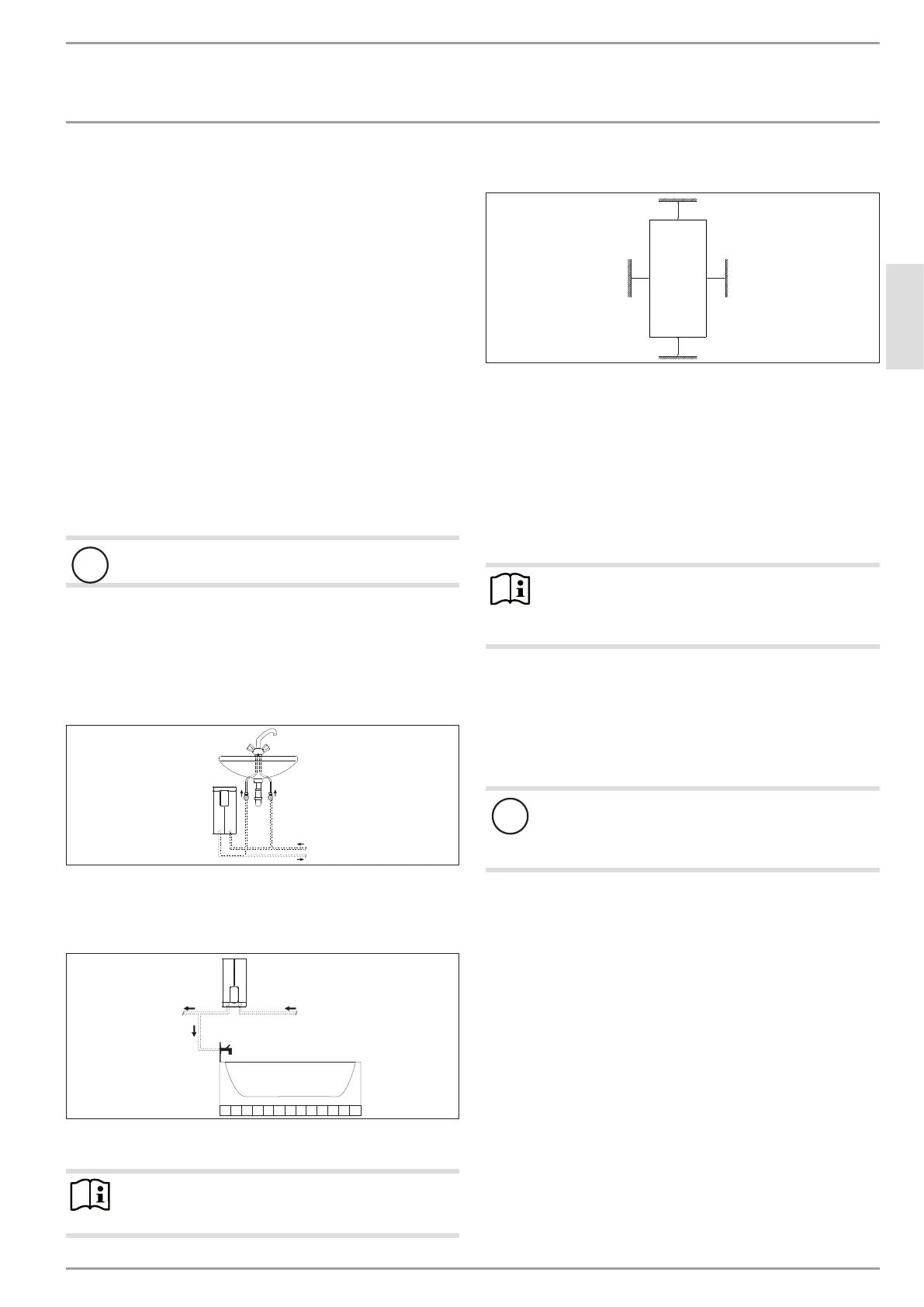

9.2 Minimum clearances

≥50≥50

≥90

≥90

D0000060809

f Maintain the minimum clearances to ensure trouble-free op-

eration of the appliance and facilitate maintenance work.

9.3 Water installation

f Flush the water line thoroughly.

Taps/valves

Use appropriate pressure taps. Open vented taps are not per-

missible.

Note

Never use the 3-way ball shut-off valve in the cold water

inlet to reduce the flow rate. The 3-way ball shut-off valve

is intended only to shut off the cold waterinlet.

Permissible water line materials

- Cold water inlet line:

Pipes made from galvanised steel, stainless steel, copper or

plastic

- DHW outlet line:

Pipes made from stainless steel, copper or plastic

!

Material losses

If plastic pipework systems are used, take into account

the maximum inlet temperature and the maximum per-

missible pressure.

Flow rate

f Ensure that the flow rate for switching on the appliance is

achieved.

f Increase the water line pressure if the required flow rate

is not achieved when the draw-off valve is fully open. If

the flow rate is still not achieved, remove the flow limiter

(see chapter "Installation/ Installation/ Removing the flow

limiter").

Loading...

Loading...