Checking

chain

lubrication

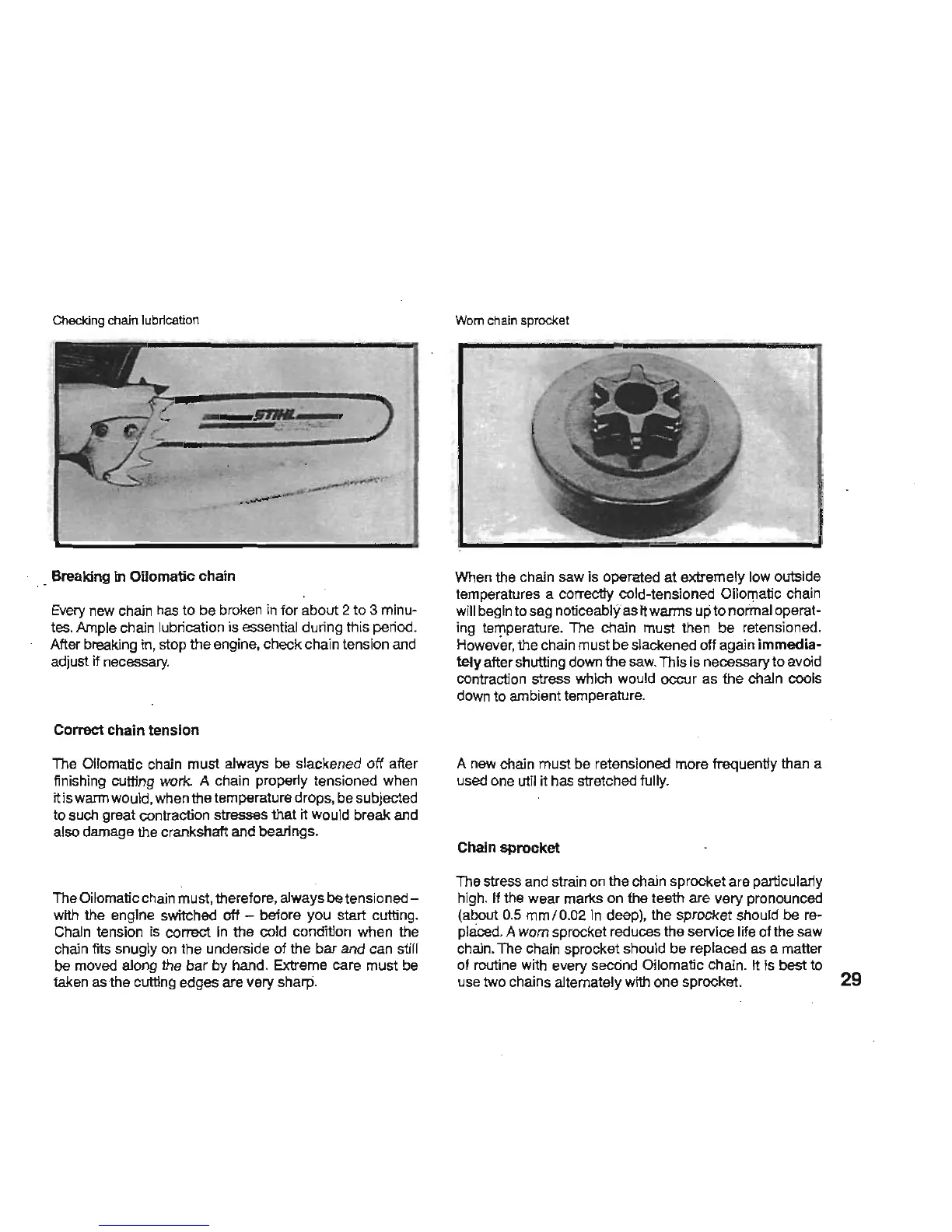

Wom

chain

sprocket

Breaking

In

OHomatic

chain

Every new chain

has

to be broken

In

for about 2 to 3 mInu-

tes. Ample chain lubrication is essential during this period.

After breaking

in

, stop

the

engine, check chain tension and

adjust if necessary.

Correct

chain

tension

The Ollomatic chain must always be slackened off after

finishing cutting

work

A chain properly tensioned when

~

is warm would, when the temperature drops, be subjected

to such great contnaction stresses that

~

would break and

also damage the crankshaft and bearings.

The Oilomatic chain must, therefore, always be tensio

ned-

w~

the engine switched off - before you start cutting.

Chain tension is correct

In

the cold condition when the

chain fits snugly

on

the underside of the bar and can still

be moved along the bar

by

hand. Extreme care must be

!eken as ·the cutting edges are very sharp.

When the chaln saw Is operated at extremely low outside

temperatures a correctfy cold-tensioned Ollorpatic chain

will begin to sag noticeabl)i"as H warms up to

noimal

operat-

ing temperature. The chaln must then be retensioned.

However, the chain must be slackened off again

immedia-

tely after shutting down the saw. This Is necessary to avoid

contraction

stress which would occur as

the

chain cools

down to ambient temperature.

A new chain must be retensloned more frequently than a

used one util h has stretched fully.

Chain

sprocket

The stress and strain

on

the chain sprocket are particularly

high.

~

the

wear

mar1<s

on the teeth are very pronounced

(about

0.5

mm/O

.

D2

In

deep), the sprocket should be re-

pl8ced. A

wom

sprocket reduces the service life

of

the saw

chain. The chain sprocket should be replaced as a matter

of routine whh every secOnd Oilomatic chain.

n Is

best

to

use two chains alternately

w~

one sprocket. 29

Loading...

Loading...