O

n

l

i

n

e

v

e

r

s

i

o

n

-

n

o

t

f

o

r

r

e

p

r

i

n

t

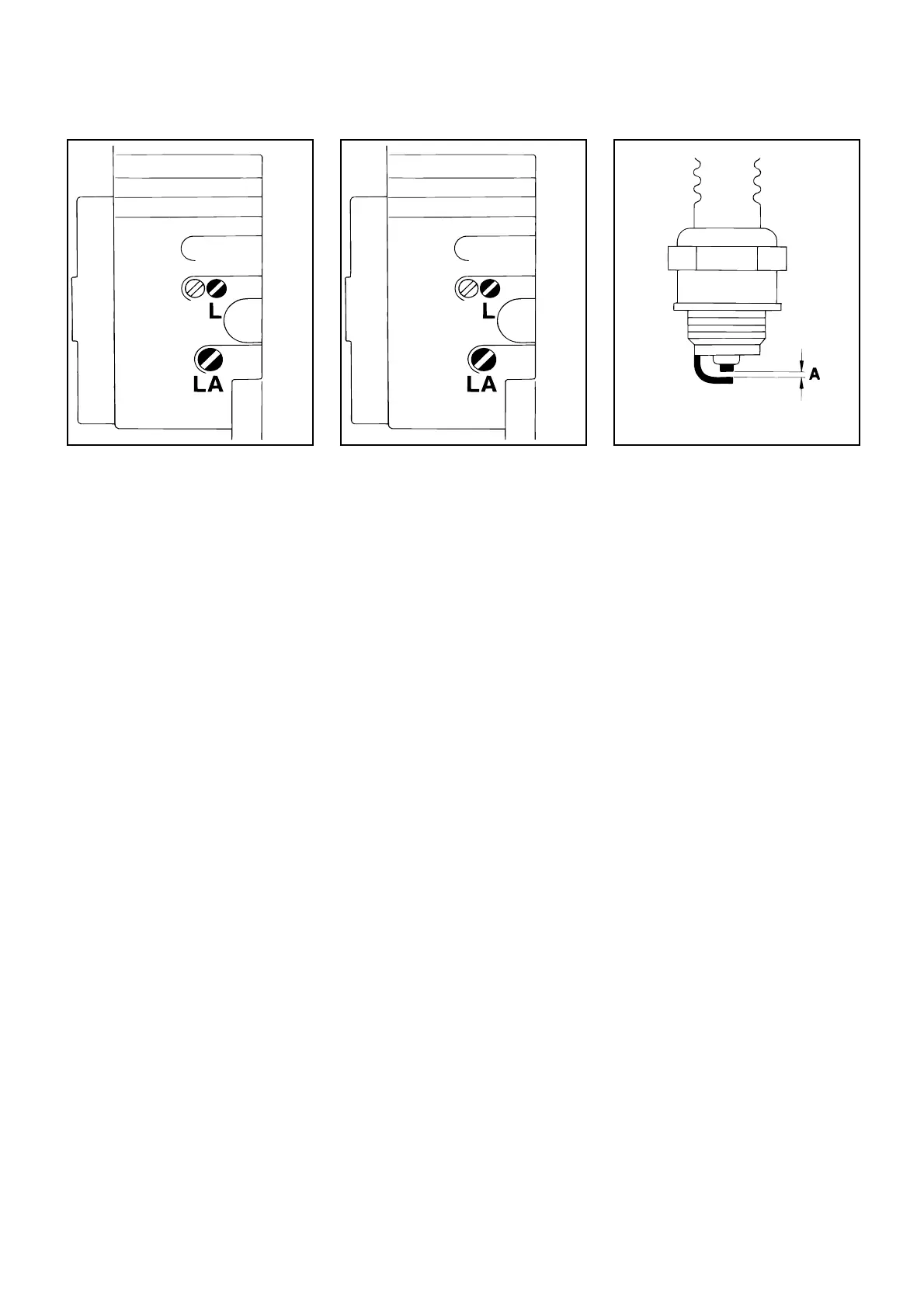

$GMXVWLQJLGOHVSHHG

It is usually necessary to change

the setting of the idle speed

adjusting screw/$ after every

correction to the low speed

adjusting screw /.

(QJLQHVWRSVZKLOHLGOLQJ

Turn the idle speed

adjusting screw/$

clockwise until engine runs

smoothly - cutting

tool must not rotate.

&XWWLQJWRROURWDWHVZKHQ

HQJLQHLVLGOLQJ

Turn the idle speed adjusting

screw /$ counterclockwise until

cutting tool stops rotating -

then back off screw about

another one half turn from that

position.

(UUDWLFLGOLQJEHKDYLRU

SRRUDFFHOHUDWLRQ

Idle setting is too lean.

Turn the low speed adjusting

screw/ counterclockwise until

engine runs and accelerates

smoothly.

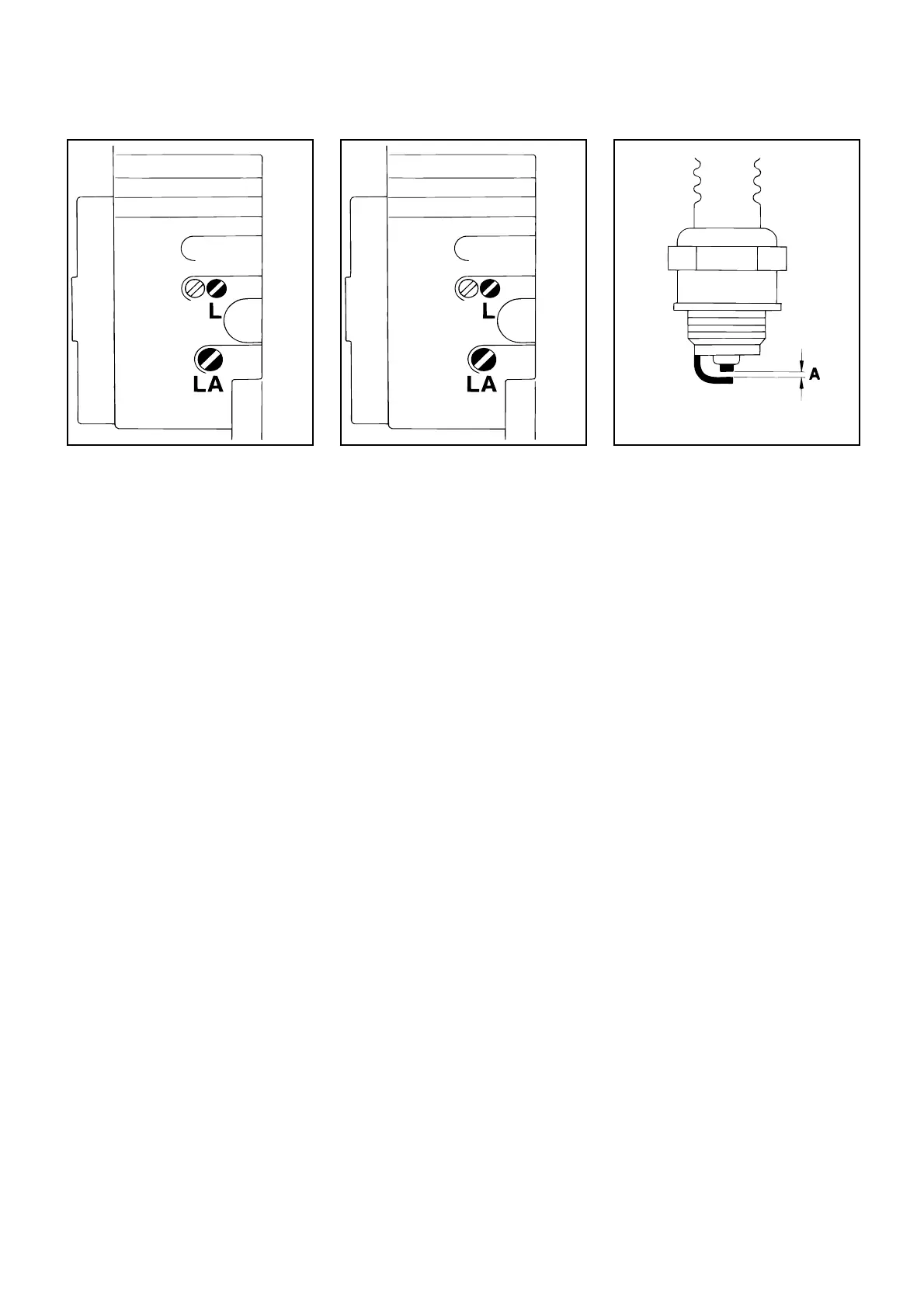

&KHFNLQJ6SDUN3OXJ

343BA046

00BA002 KN

Wrong fuel mix (too much engine oil in

the gasoline), a dirty air filter and un-

favorable running conditions (mostly at

part throttle etc.) affect the condition of

the spark plug. These factors cause

deposits to form on the insulator nose

which may result in trouble in operation.

If engine is down on power, difficult to

start or runs poorly at idling speed,

first check the spark plug.

•

Remove spark plug -

see "If engine doesn’t start:"

•

Clean dirty spark plug.

•

Check electrode gap $ -

it should be 0.7 - 0.8 mm

(about 0.03") -

readjust if necessary.

343BA046

Loading...

Loading...