O

n

l

i

n

e

v

e

r

s

i

o

n

-

n

o

t

f

o

r

r

e

p

r

i

n

t

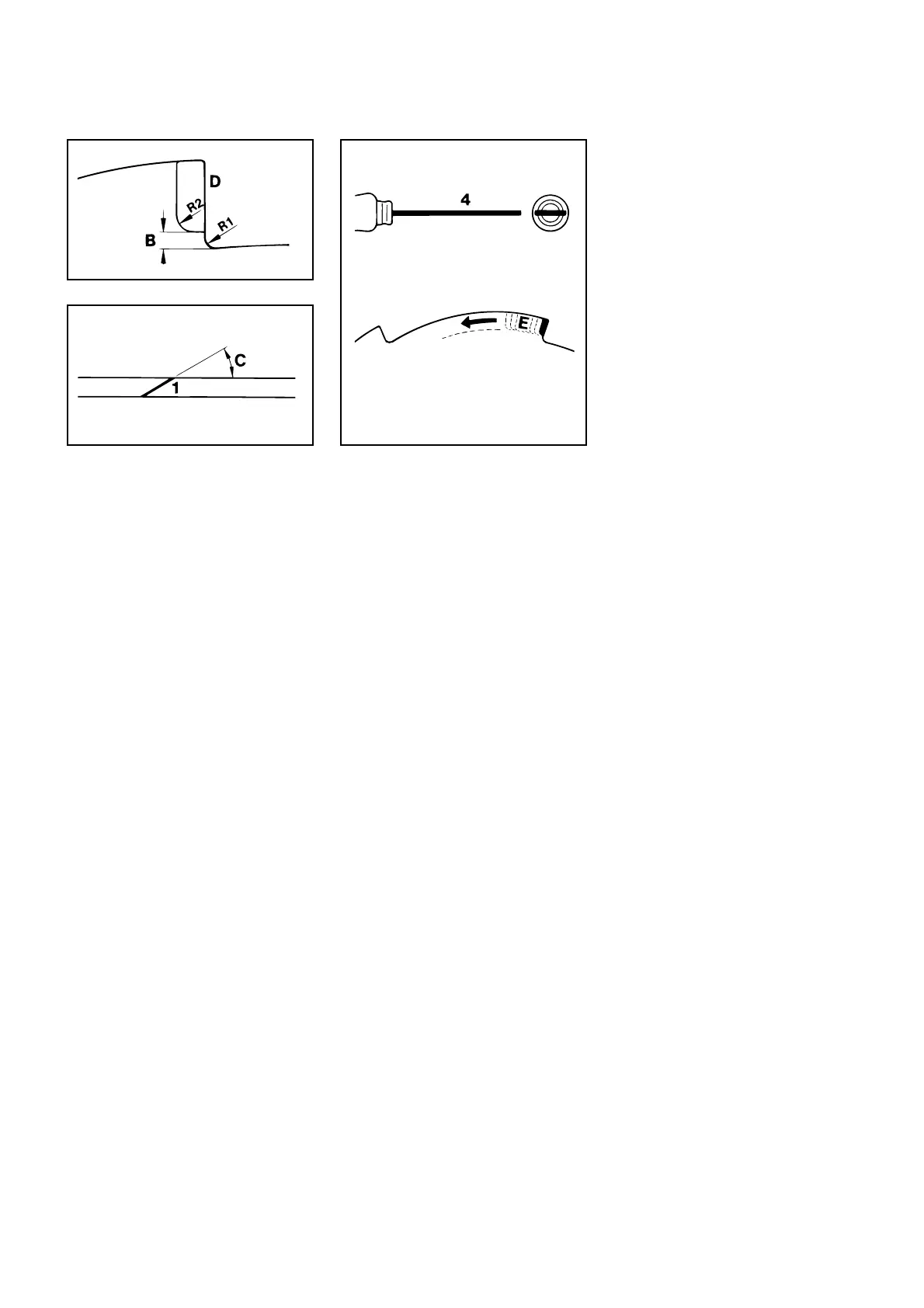

0HDVXUHPHQWVDQGDQJOHVIRU

UHVKDUSHQLQJ

Leave clearance of 2mm/5/64" %

between cutting edge and parent

blade - 5should be 2mm/5/64".

Radius5is 2.5mm/7/64"and is

obtained automaticallyif you use

the specified file and maintain

a filing angle of 30°&.

Cutting edge ' must be exactly

in line with center of blade’s

mounting hole.

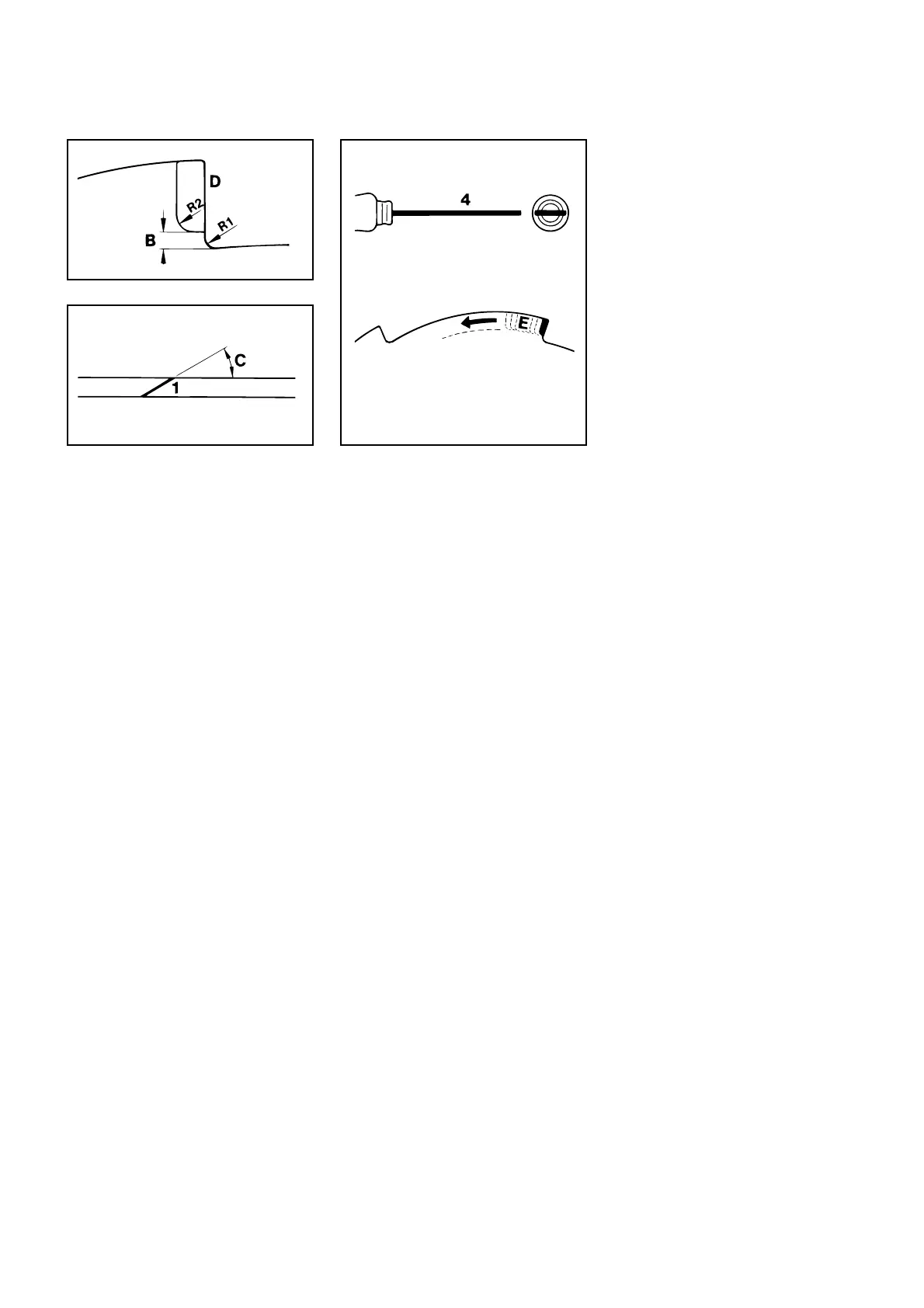

6KDUSHQFRUUHFWO\

•

If slightly dull:

Use flat file 0814 212 3310 -

In case of more serious wear or

nicks: Resharpen with a grinder.

•

File back the cutting edge

parallel to the lines ( (see

illustration).

•

Resharpen frequently, take

away as little material as

possible - two or three strokes

of the file are usually enough.

357BA059 KN

357BA061 KN

357BA060 KN

2SHUDWLQJ,QVWUXFWLRQV

'XULQJEUHDNLQSHULRG

A factory new machine should not be

run at high revs (full throttle off load) for

the first three tank fillings. This avoids

unnecessary high loads during the

break-in period.

As all moving parts have to bed in

during the break-in period, the

frictional resistances in the engine

are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

'XULQJRSHUDWLRQ

After a long period of full-throttle

operation, allow engine to run for a while

Loading...

Loading...