•

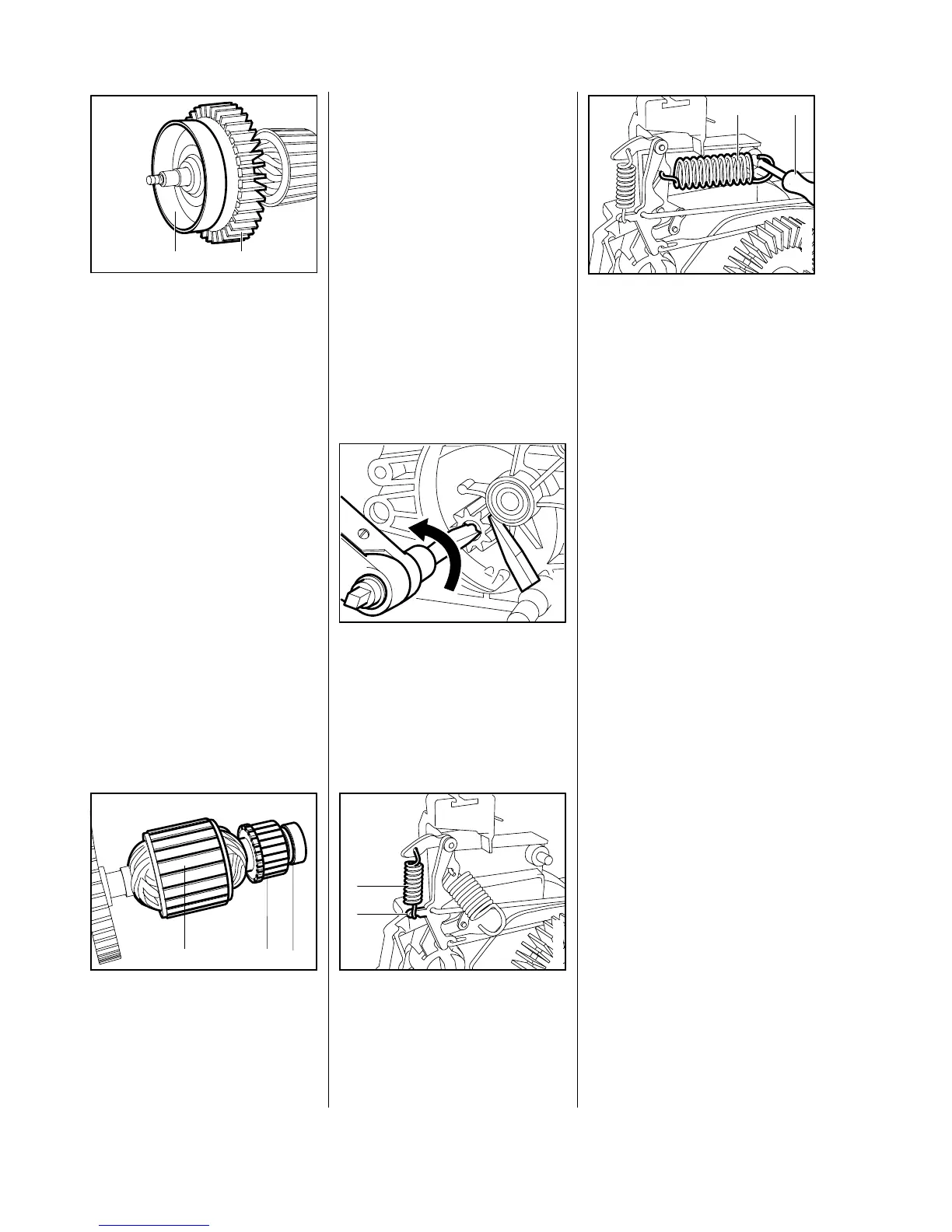

Examine brake drum (1) and fan-

wheel (2), replace if necessary -

see 5.4.

Note: If brake drum has to be re-

placed, also check the brake band

- see 8.1

- If brake drum is still serviceable,

clean and roughen its friction

face with emery paper or cloth

(grain size approx. 120

µ

m).

•

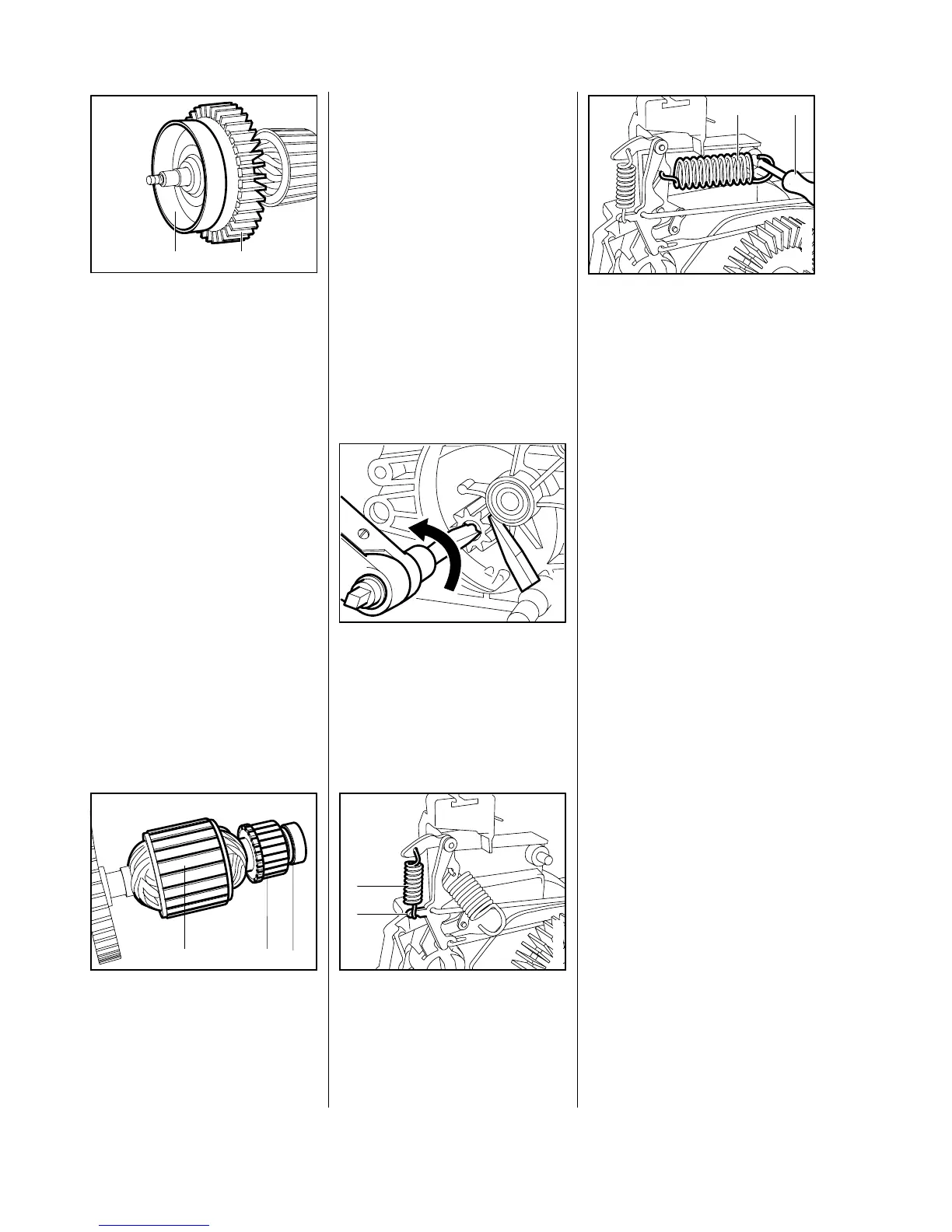

Inspect the rotor core assembly

(1) for damage and replace the

rotor if necessary. The fanwheel

and ball bearing have to be remo-

ved for this purpose - see 5.4

and 5.3.

•

Inspect the commutator (2).

Note: In case of minor running

marks, dress the commutator

with emery cloth. If running

marks are severe, fit new rotor.

•

Examine ball bearing (3) and

replace if necessary - see 5.3.

Install in the reverse sequence.

- Clean thread of slotted nut and

rotor stub with standard commer-

cial, solvent-based degreasant

containing no chlorinated or

halogenated hydrocarbons -

see 10.2.

- Coat thread of slotted nut with

Loctite, see 10.2, and screw

slotted nut into pinion.

•

Hold pinion steady and tighten

down slotted nut to 8.0 Nm

(5.9 lbf.ft).

•

Attach smaller spring (1) to

brake lever (2).

•

Use assembly tube (2) 1117 890

0900 to hook larger spring (1) to

pivot pin.

- Torque down gear housing

screws to 3.0 Nm (2.2 lbf.ft) and

screw on hand guard to 4.5 Nm

(3.3 lbf.ft).

VA

2

1

100RA040

VA

100RA039

1 2

VA

100RA041

1

2

3

100RA043

VA

1 2

VA

100RA042

12

Loading...

Loading...