30

English / USA

FS 120, FS 120 R, FS 200, FS 200 R, FS 250, FS 250 R

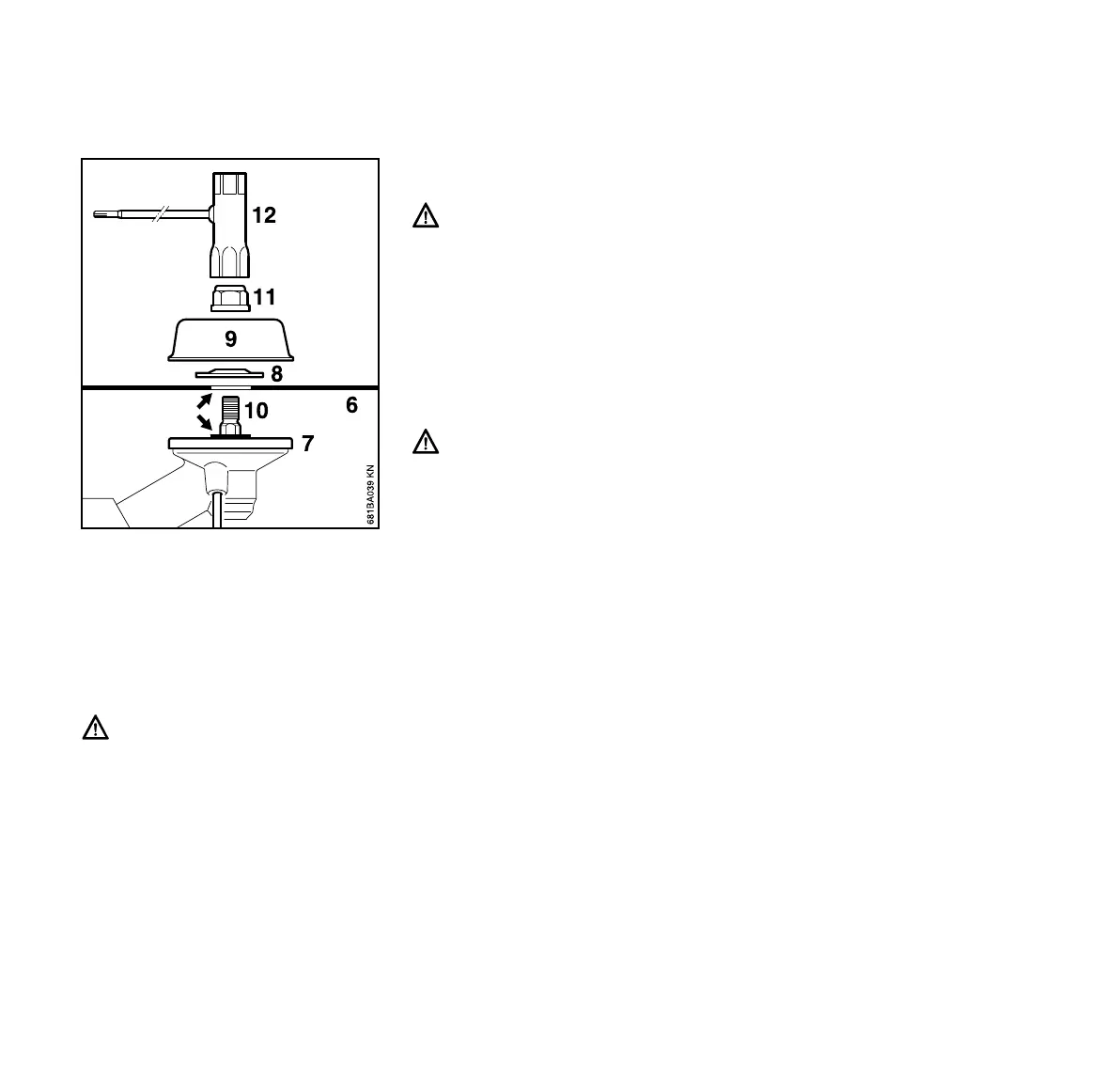

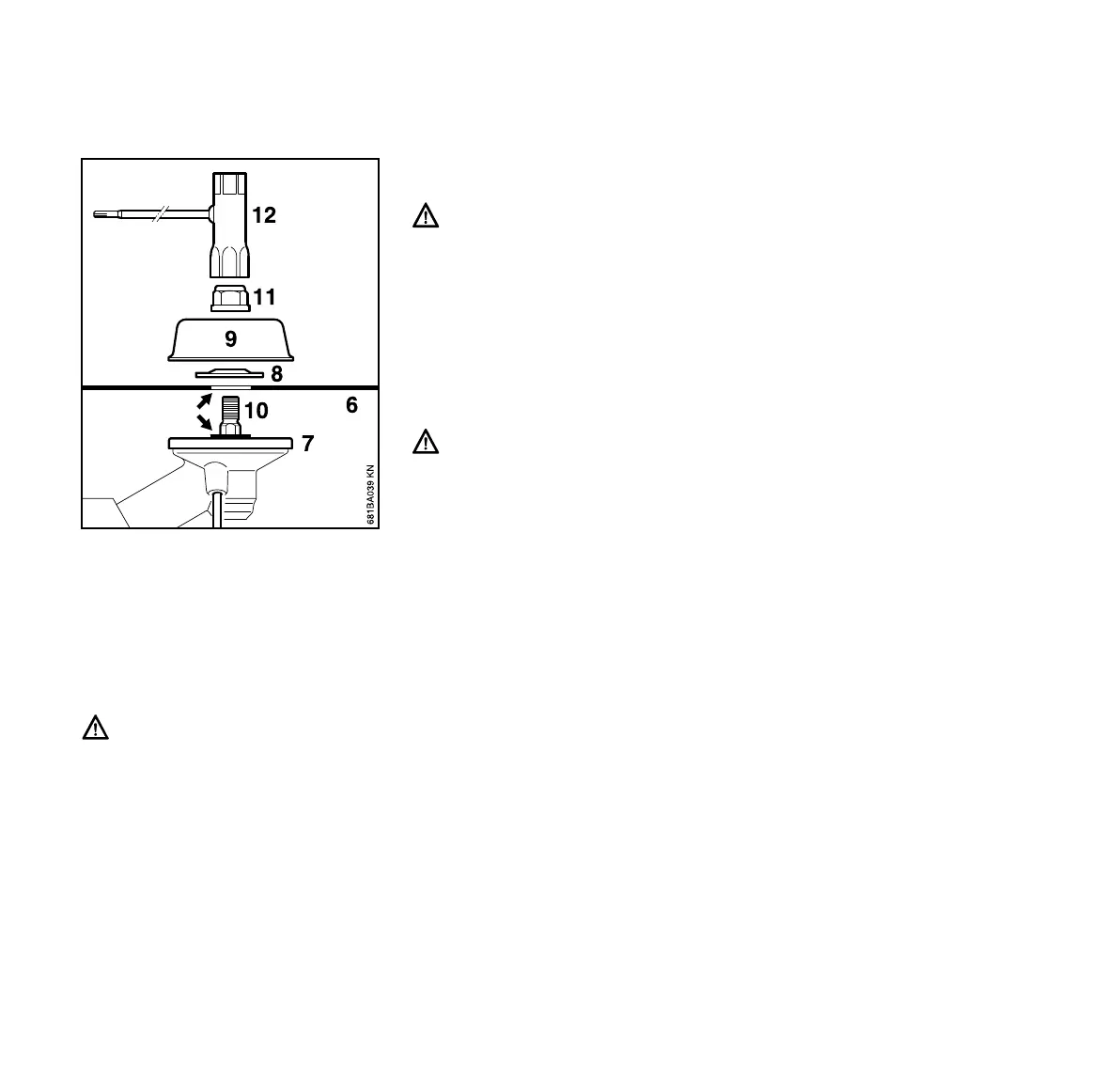

: Lay your machine on its back with

the gearhead facing upward.

Cutting edges of (1) and (3) may

point in either direction.

Cutting edges of (2), (4) and (5)

must point clockwise.

Direction of rotation is marked by

arrow on inside of cutting head

deflector or limit stop.

: Place the cutting tool (6) on the

thrust plate (7).

Collar (see arrows) must locate in

cutting tool’s mounting hole.

: Slip thrust washer (8) and rider

plate (9) over the output shaft (10).

: Block the output shaft and

: Screw the mounting nut (11) with

the combination wrench (12) onto

the output shaft counterclockwise

and tighten down firmly.

If the mounting nut is too loose,

fit a new one.

Removing cutting tool

: Block the output shaft.

: Unscrew the nut clockwise.

: Removing the cutting tool – do not

remove the thrust plate (7).

This engine is certified to operate on

unleaded gasoline and the STIHL two-

stroke engine oil at a mix ratio of 50:1.

Your engine requires a mixture of high-

quality gasoline and quality two-stroke

air cooled engine oil.

Use mid-grade unleaded gasoline with a

minimum octane rating of 89 (R+M/2). If

the octane rating of the mid-grade

gasoline in your area is lower, use

premium unleaded fuel.

Fuel with a lower octane rating may

increase engine temperatures. This, in

turn, increases the risk of piston seizure

and damage to the engine.

The chemical composition of the fuel is

also important. Some fuel additives not

only detrimentally affect elastomers

(carburetor diaphragms, oil seals, fuel

lines, etc.), but magnesium castings and

catalytic converters as well. This could

cause running problems or even

damage the engine. For this reason

STIHL recommends that you use only

nationally recognized high-quality

unleaded gasoline!

Fuel

Loading...

Loading...