17HS 81 R, HS 81 T

English / USA

When engine begins to fire:

: Move the choke lever to e and

continue cranking.

As soon as engine runs

: Open the throttle wide, the starting

throttle button pops out and the

engine settles down to idle speed.

At very low outside temperatures –

warm up the engine

As soon as engine runs:

: Allow engine to run in starting

throttle position for about 10

seconds.

: Then open the throttle wide, the

starting throttle button pops out and

the engine settles down to idle

speed.

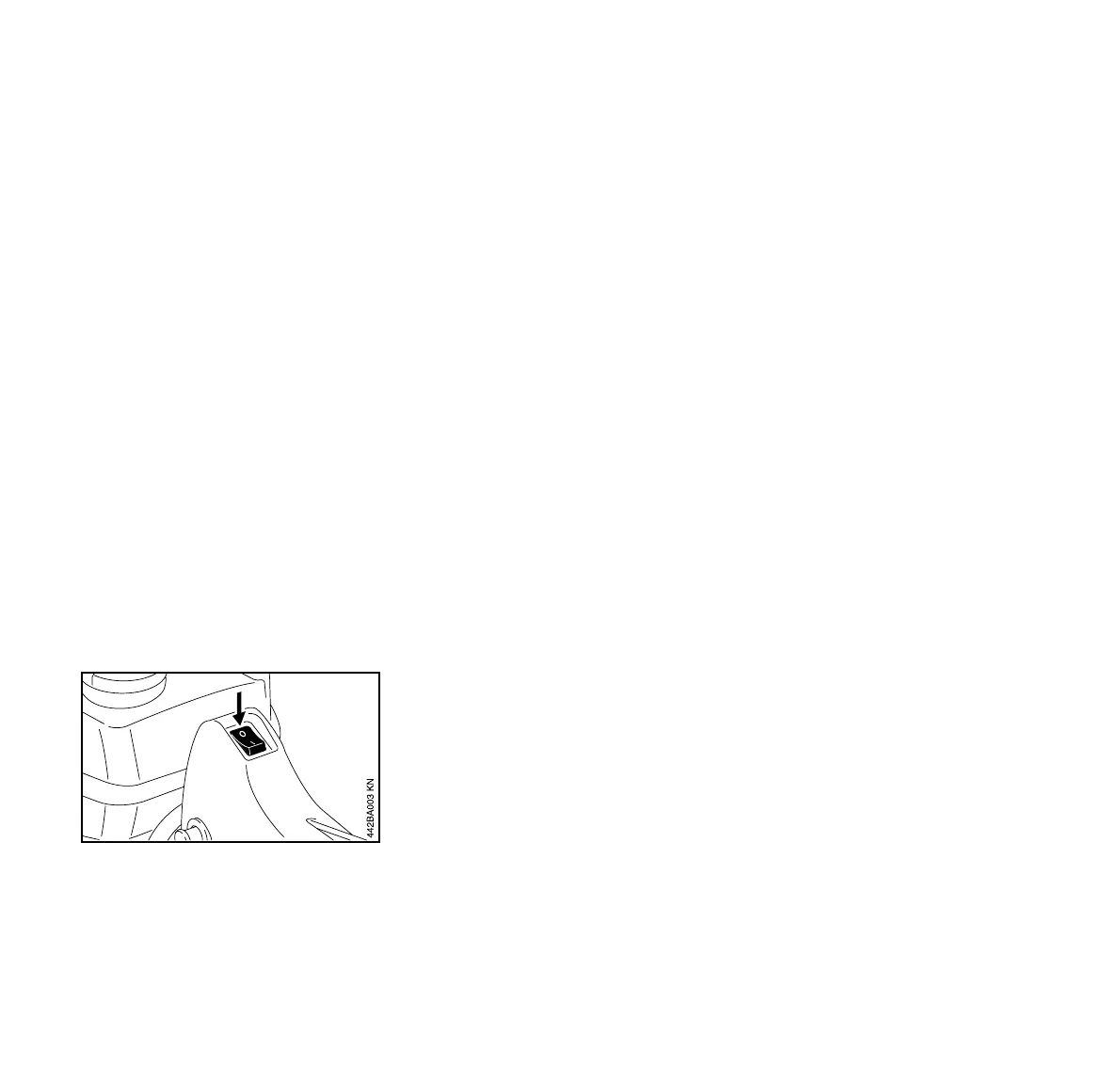

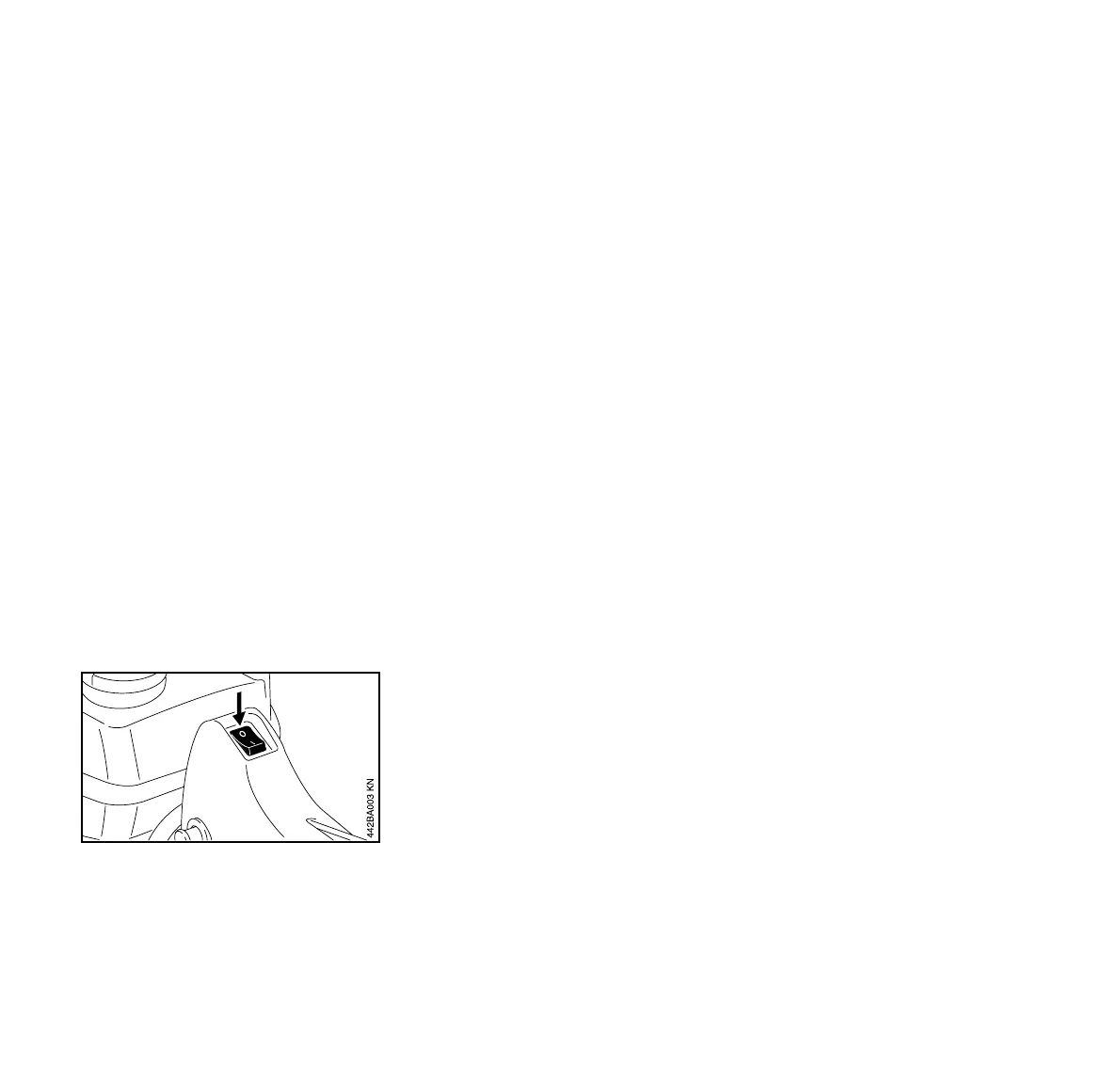

Stopping the engine

: Set the stop switch to 0.

If the engine doesn’t start

Fuel tank has been run dry and then

refueled

: Press the fuel pump bulb at least

fives times, even if it is already filled

with fuel.

: Now start the engine.

Engine is flooded

: If you did not move the choke lever

to e quickly enough after the

engine began to fire, the engine is

flooded.

: Set choke lever to e even if the

engine is cold.

: Now start the engine with a few

brisk pulls of the starter rope.

During break-in period

A factory new machine should not be run

at high revs (full throttle off load) for the

first three tank fillings. This avoids

unnecessary high loads during the

break-in period. As all moving parts

have to bed in during the break-in

period, the frictional resistances in the

engine are greater during this period.

The engine develops its maximum

power after about 5 to 15 tank fillings.

During operation

After a long period of full-throttle

operation, allow engine to run for a while

at idle speed so that the heat in the

engine can be dissipated by flow of

cooling air. This protects engine-

mounted components (ignition,

carburetor) from thermal overload.

After finishing work

Wait for engine to cool down. Drain the

fuel tank. Store the machine in a dry

place. Check tightness of nuts and

screws (not adjusting screws) at regular

intervals and retighten as necessary.

Operating Instructions

Loading...

Loading...