41MS 231, MS 231 C, MS 251, MS 251 C

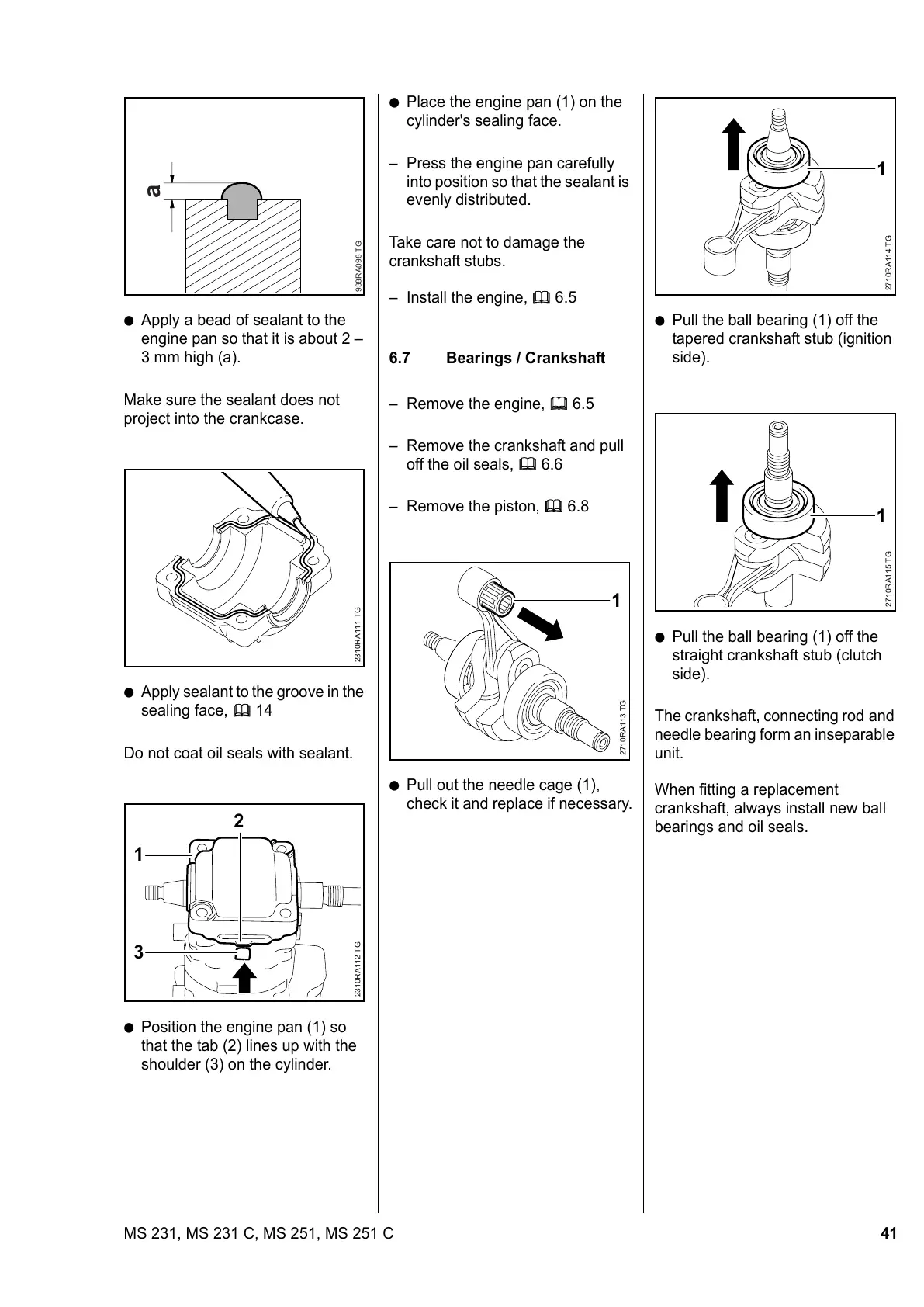

: Apply a bead of sealant to the

engine pan so that it is about 2 –

3 mm high (a).

Make sure the sealant does not

project into the crankcase.

: Apply sealant to the groove in the

sealing face, b 14

Do not coat oil seals with sealant.

: Position the engine pan (1) so

that the tab (2) lines up with the

shoulder (3) on the cylinder.

a

938RA098 TG

2310RA111 TG2310RA112 TG

1

3

2

: Place the engine pan (1) on the

cylinder's sealing face.

– Press the engine pan carefully

into position so that the sealant is

evenly distributed.

Take care not to damage the

crankshaft stubs.

– Install the engine, b 6.5

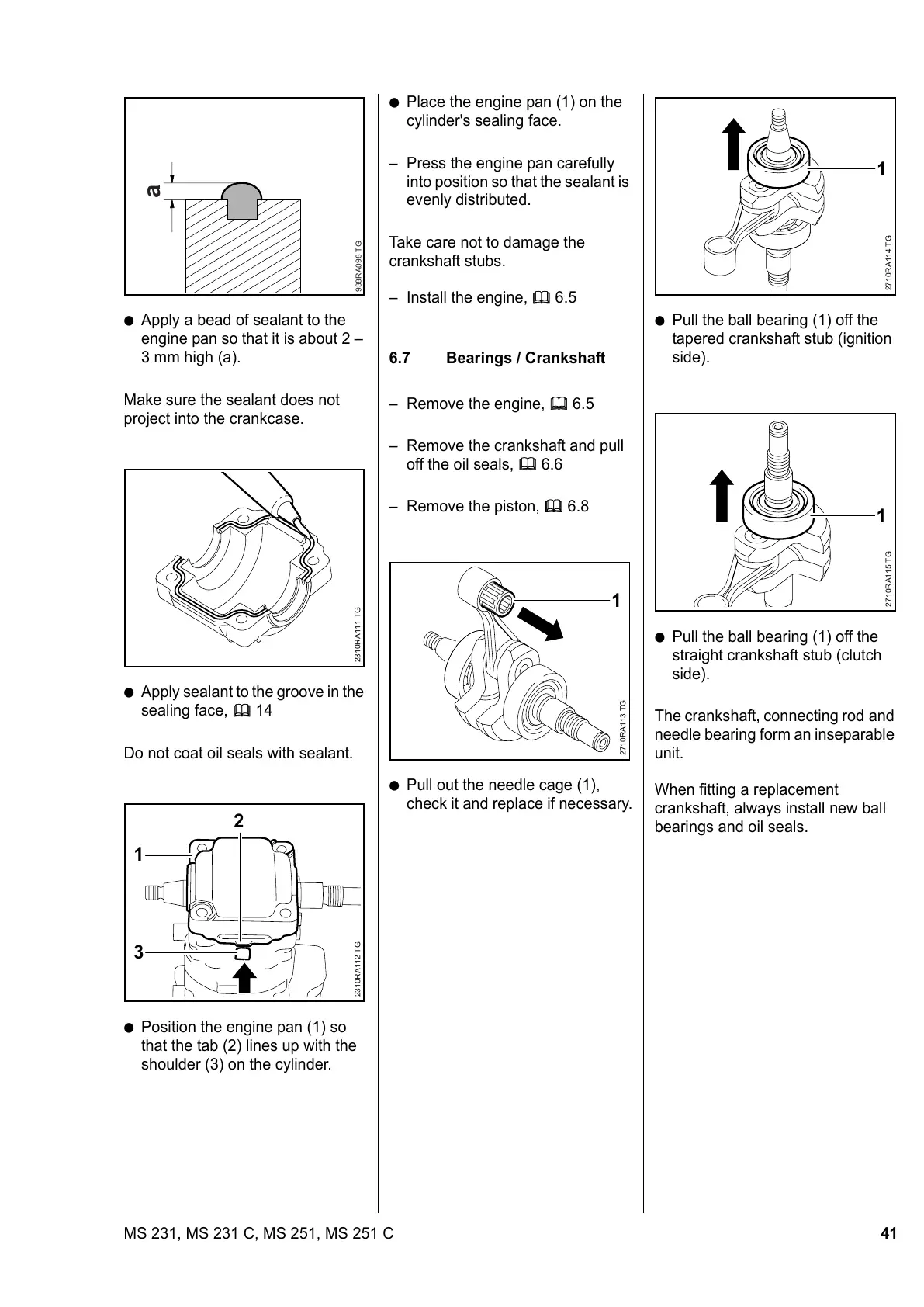

6.7 Bearings / Crankshaft

– Remove the engine, b 6.5

– Remove the crankshaft and pull

off the oil seals, b 6.6

– Remove the piston, b 6.8

: Pull out the needle cage (1),

check it and replace if necessary.

2710RA113 TG

1

: Pull the ball bearing (1) off the

tapered crankshaft stub (ignition

side).

: Pull the ball bearing (1) off the

straight crankshaft stub (clutch

side).

The crankshaft, connecting rod and

needle bearing form an inseparable

unit.

When fitting a replacement

crankshaft, always install new ball

bearings and oil seals.

2710RA114 TG

1

2710RA115 TG

1

Loading...

Loading...