- 15 -

OPERATION

ELECTRIC MOTORS - Use the proper size (3) wire

(grounded) extension cord, conforming to the National

Electric Code and Local Ordinances. DO NOT use (2)

wire extension cord. Check any extension cord which

you plan on using carefully for broken connectors, bare

wires and damaged insulation. DO NOT use any cord

found to be in poor condition. Make sure the extension

cord is not routed through standing water and that all

the connections are tight. Use the shortest extension

cord possible. Turn motor on.

TO STOP THE ENGINE / MOTOR

GASOLINE ENGINES - Depress kill switch located

on stationary cowl half and hold down until engine

stops completely. Consult the ENGINE MANUAL

included with this unit for specific instructions. IF

THE MIXER IS TO BE LEFT UNATTENDED FOR

ANY LENGTH OF TIME OR IF THE MIXER IS TO

BE TOWED TO A NEW LOCATION, CLOSE THE

FUEL VALVE UNDER THE GAS TANK.

ELECTRIC MOTORS - TURN THE MOTOR OFF.

IF THE MIXER IS TO BE LEFT UNATTENDED

FOR ANY LENGTH OF TIME, DISCONNECT THE

POWER CORD.

OPERATION

Start the engine / motor as instructed above and allow

gasoline engines to reach operating temperatures.

Close and latch the engine cowl. NEVER operate the

mixer with cowl open.

With drum operating between 20 - 25 RPM the mixer is

now ready for the addition of the concrete mix. For

best results proceed as follows:

1. Pour the required amount of water into

drum.

2. Add the required amount of gravel.

3. Add the required amount of cement.

4. Add the required amount of sand.

By adding the water and gravel first the drum will be

kept clean and a good tumbling action will be added.

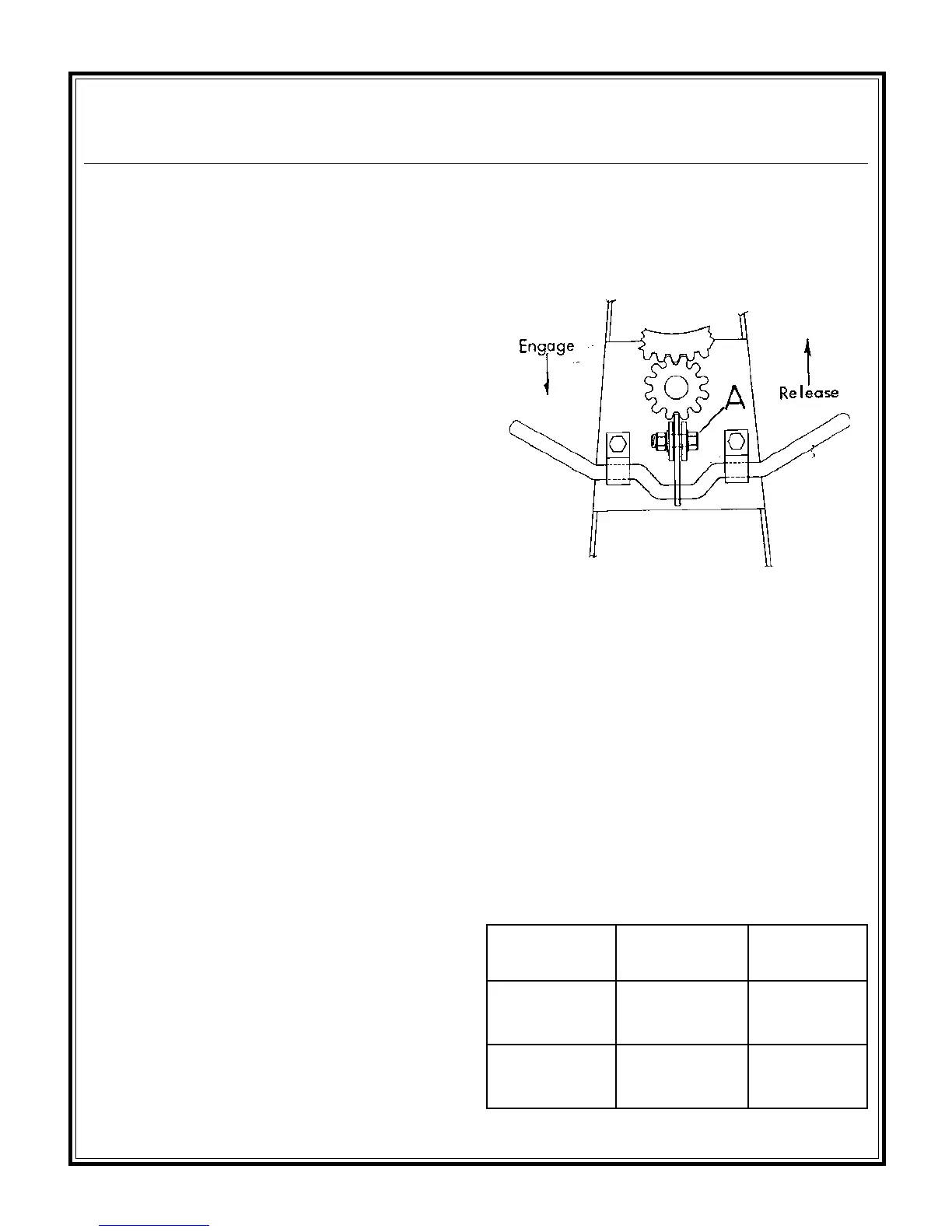

To discharge concrete, grasp handwheel firmly with

one hand and release tilt brake by pushing up on the tilt

handle with the other, (see diagram below).

To prevent accidental discharge, never release brake

without holding the handwheel firmly. Do not attempt

to grab handwheel to stop an accidental discharge,

serious injury could result. Always make sure that the

brake is fully engaged after discharge of concrete and

before reloading drum.

After discharge of concrete, immediately pour in the

required amount of water for the next batch.

NOTE: When servicing brake mechanism, bolt A

should be tightened so that approximately 17 - 18

pounds of force is required to release the brake. This

will prevent accidental discharge due to vibration.

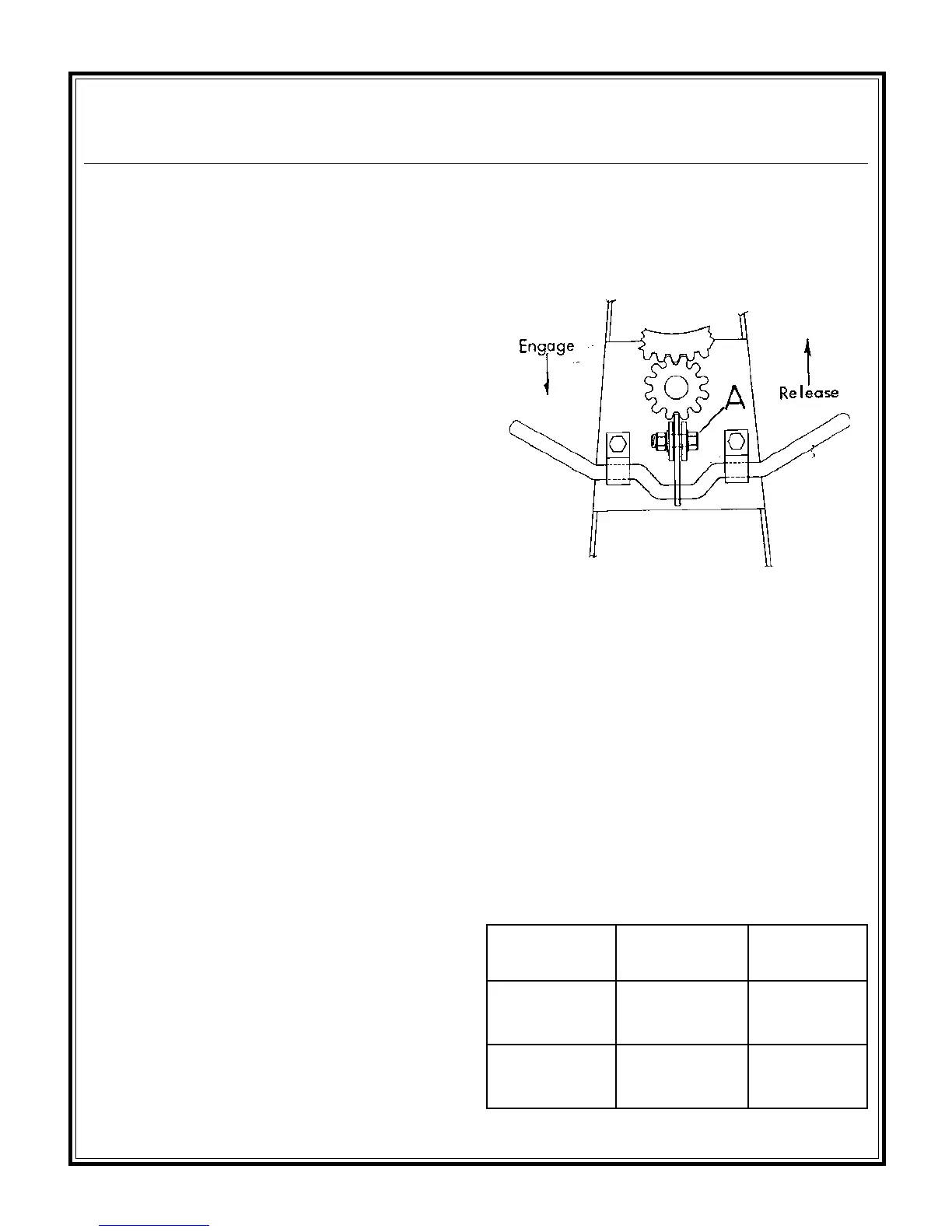

CAPACITIES

* Maximum batch size depends on mix and type

of aggregate used.

65CMED 95CMED

2/3 Bag Mixer 1 Bag Mixer

Total Drum

Volume 9.0 cu. ft. 15.1 cu. ft.

Max. Batch

Size* 6.0 cu. ft. 9.0 cu. ft.

65CMED & 95CMED

Loading...

Loading...