- 18 -

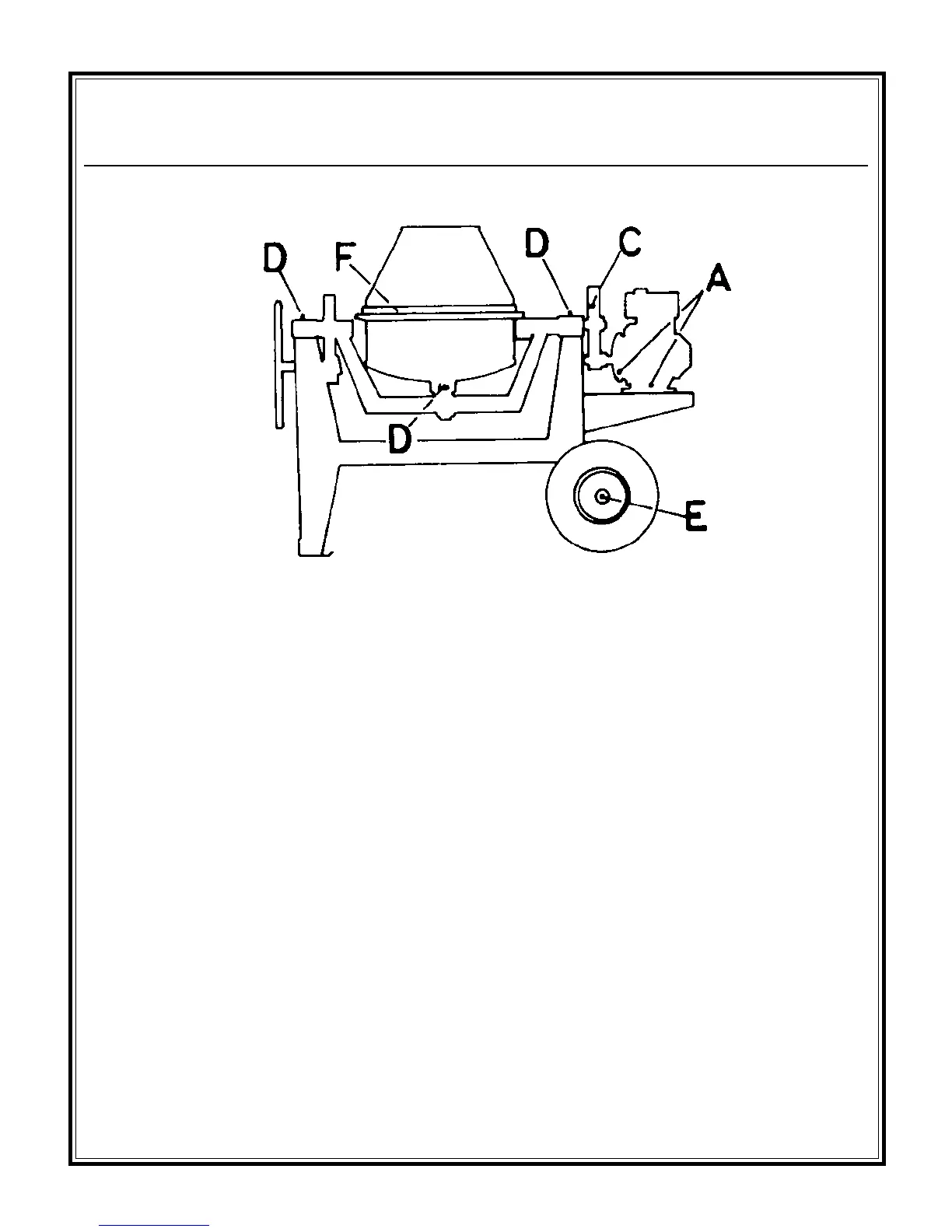

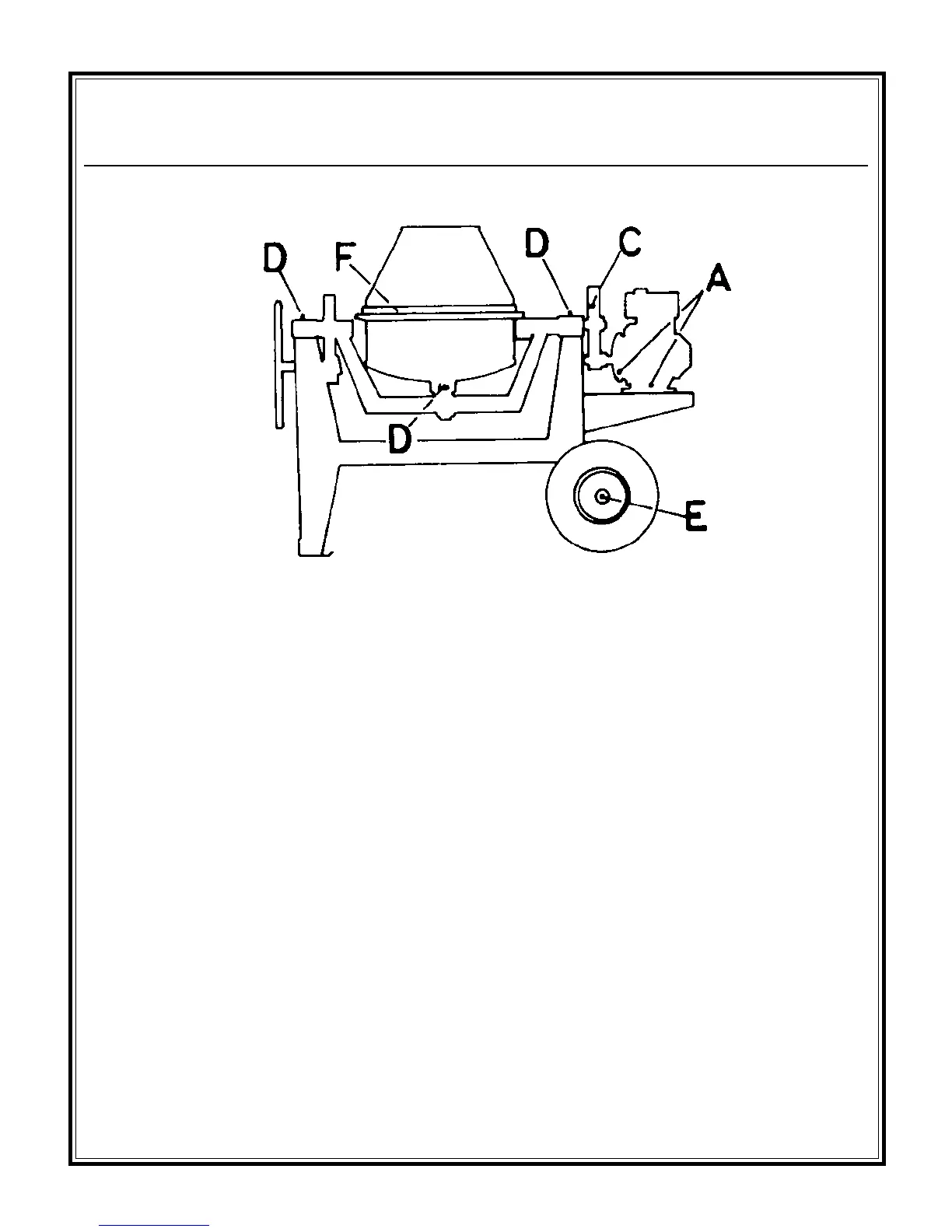

MAINTENANCE

Schedule

A. ENGINE--Daily check the oil levels in the engine and engine reduction unit. The engine warranty is VOID if run

without oil . Since there are many engine options available on this mixer, consult the ENGINE MANUAL for

specific recommendation as to oil level, oil type required and frequency of oil changes required. For maximum

service life from the engine, follow those recommendations.

B. PILLOW BLOCK BEARINGS--*WEEKLY - Grease idler shaft pillow block bearings on electric drive

models.

C. CHAIN & SPROCKETS--WEEKLY - Lubricate chain and sprockets on chain drive models with a few drops of

SAE 30 motor oil or any spray chain lube.

D. TRUNNIONS & DRUM SPINDLE--MONTHLY - Grease trunnions (2) places and drum spindle (1) place.

E. WHEEL HUBS--EARLY - Repack (4) tapered roller bearings in wheel hubs and replace wheel seals. Install

washer and nut. Torque to 20 ft. lbs., back off one turn, torque to 7 ft. lbs., back off to first slot in nut and insert

cotter key.

F. PINION & RING GEAR--DO NOT lubricate pinion and ring gear. They will collect abrasive materials which

will accelerate wear.

NOTE: Cowl removed

for clarity. Do not operate

mixer with cowl removed.

* See Exploded Views in the Service/

Parts Manual for exact location.

Loading...

Loading...