2

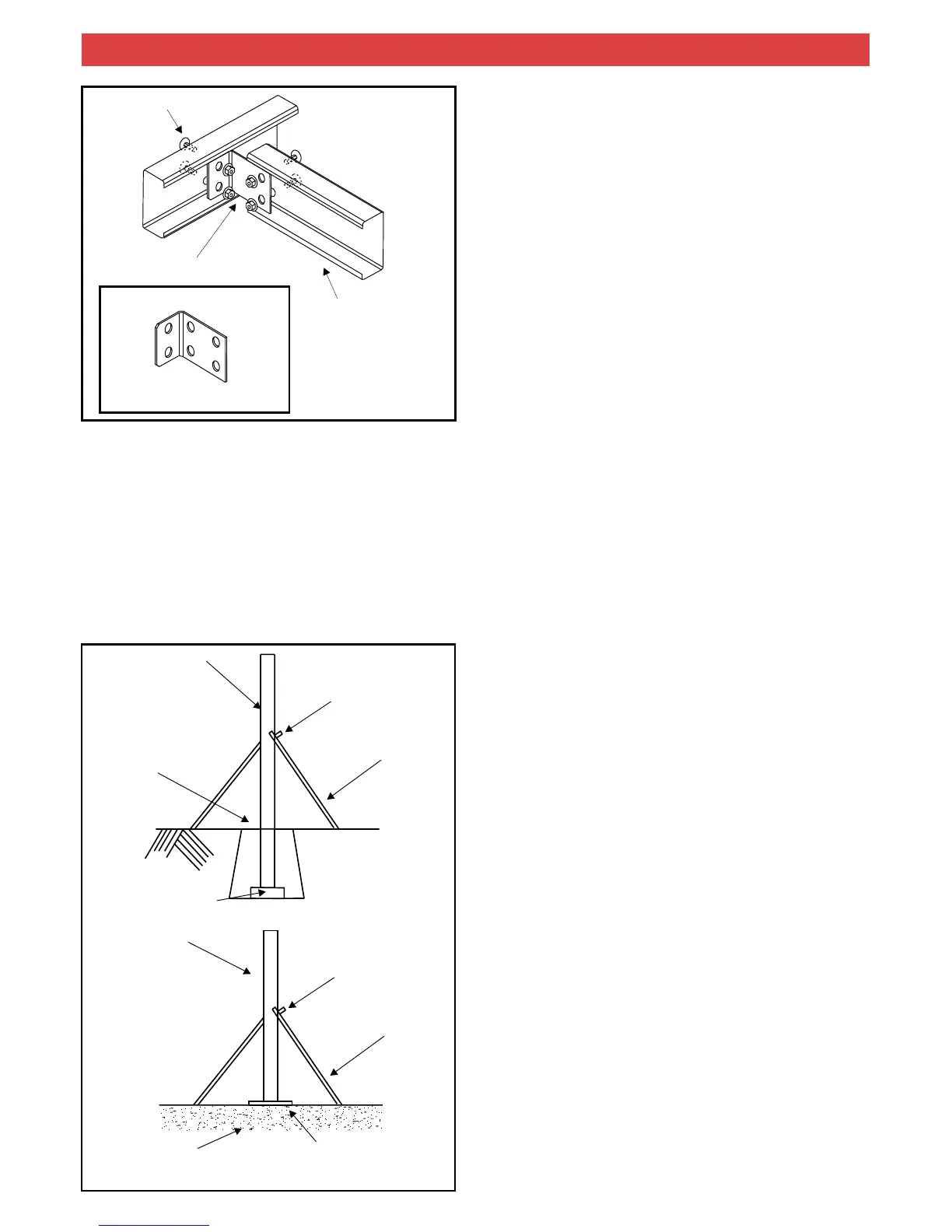

BRACES

BRICK

POST

PRE-DUG HOLE

CLAMP

4A

POST

CLAMP

BRACES

CONCRETE

FOOTING

PLATE

4B

Note:

Note:

The type of carport will determine whether or not

intermediate beams and purlins are present. Figure 1

indicates how to identify intermediate beams and purlins.

Before predrilling any holes it is recommended a

smaller pilot hole be drilled to make the job easier.

Stand the posts in the appropriate footing locations and

brace in position with clamps and struts (Figure 4).

3.2 POSTS

Note:

Note:

Note:

Note:

For in concrete carports, posts need to be cut to allow

for a 1° fall towards the gutter and downpipe end.

For on concrete carports, two different post heights

will have been supplied to allow for a slight fall toward one

end of the unit at which the gutter and downpipe will be

located. Ensure that the two posts at each end of the unit

are the same height and that the gutter and downpipe will

be located in the correct location.

Bolt holes should have been pre-drilled at the ends of the

perimeter beams.

Lift the perimeter beams into place and support on

adjustable construction props. Bolt these beams to the

posts using the M12 bolts and washers supplied (Figure 2).

The side beams should sit on the inside face of the

posts while the front and rear beams should sit on the

outside face of the posts.

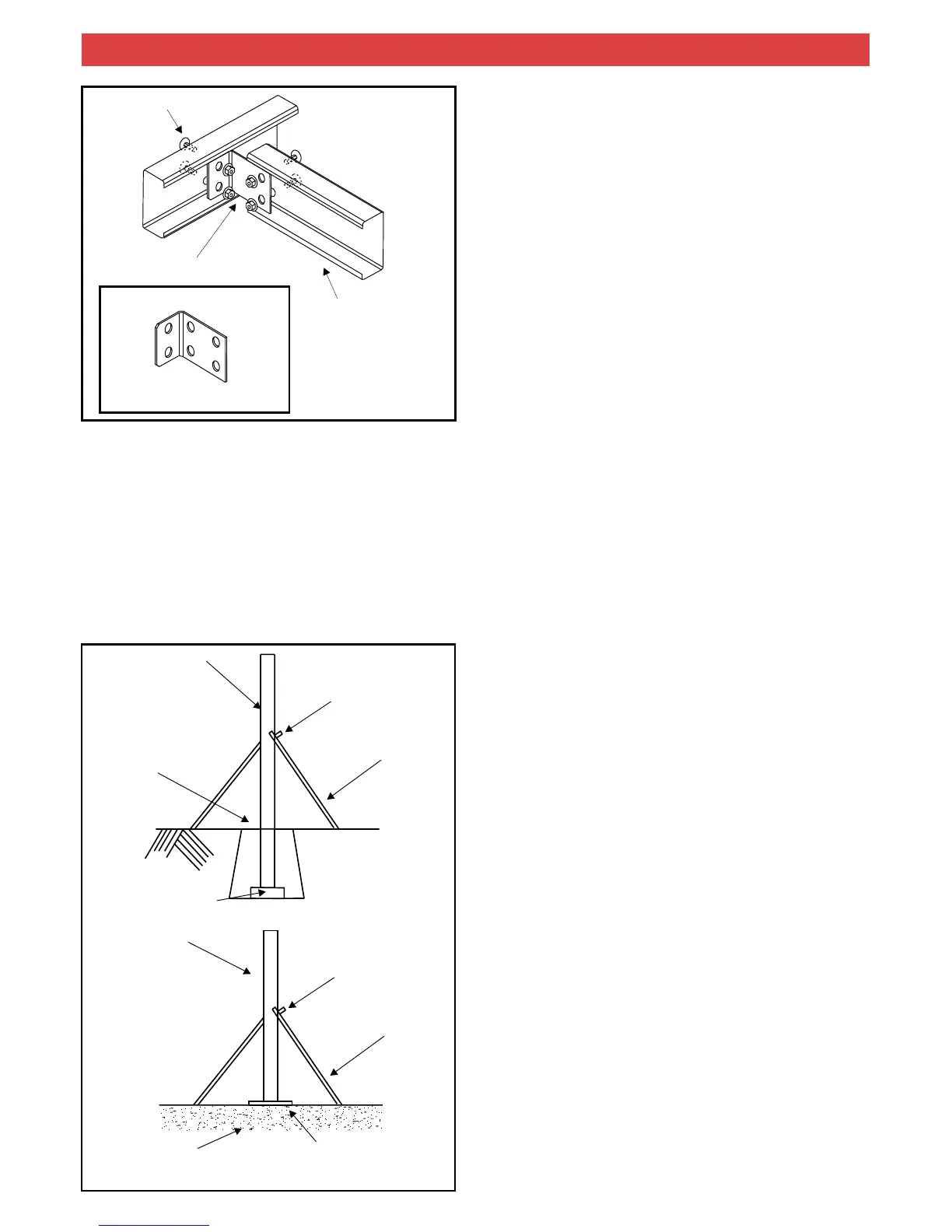

If intermediate beams and purlins are required, bolt holes

should have been pre-drilled at each end to match those

already present in the supplied angle brackets. Attach an

angle bracket to each end of the intermediate beams and

purlins using the M10 bolts and washers supplied (Figure

3). If General Purpose brackets have been supplied, use

M12 bolts and washers.

The supplied drawing will indicate the location of all internal

beams. Lift into position and support on adjustable

construction props

Drill 11mm holes (14mm for General Purpose Bracket) at

the appropriate locations in the adjoining beams to match

the hole locations in the angle brackets. Bolt together using

the M10 bolts and washers supplied (Figure 3) or M12 bolts

and washers for General Purpose Bracket (Figure 3).

Now that the basic framework has beam erected, check all

dimensions are correct and the diagonals for squareness.

Check that the columns are in line and plumb and that the

falls are correct for roof and gutter.

Concrete the footings and leave overnight to cure.

The concrete should be finished slightly raised

towards the column, ensuring water runs away from the

column (Figure 5).

3.3 PERIMETER BEAMS

3.4 INTERMEDIATE BEAMS AND PURLINS

4.0 FOOTINGS

4.1 IN GROUND FOOTING

3

INTERMEDIATE BEAM

ANGLE BRACKET

M10 BOLTS & WASHERS

GENERAL PURPOSE BRACKET MAY BE

USED WITH M12 BOLTS & WASHERS

ALTERNATIVELY,

Loading...

Loading...