/07.2016/G20

21

1.50

1.45

1.40

1.35

1.30

1.25

1.20

1.15

1.10

1.05

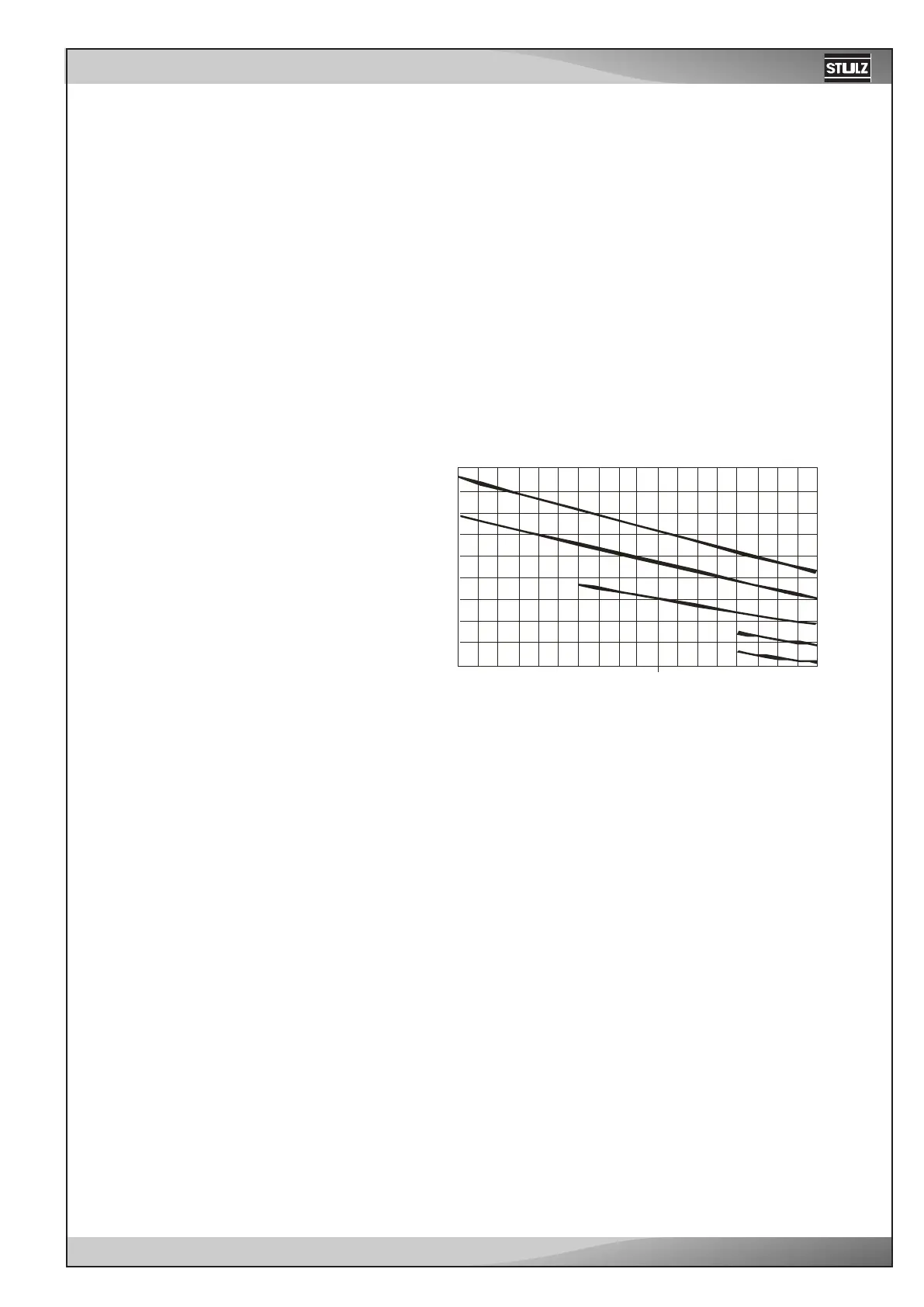

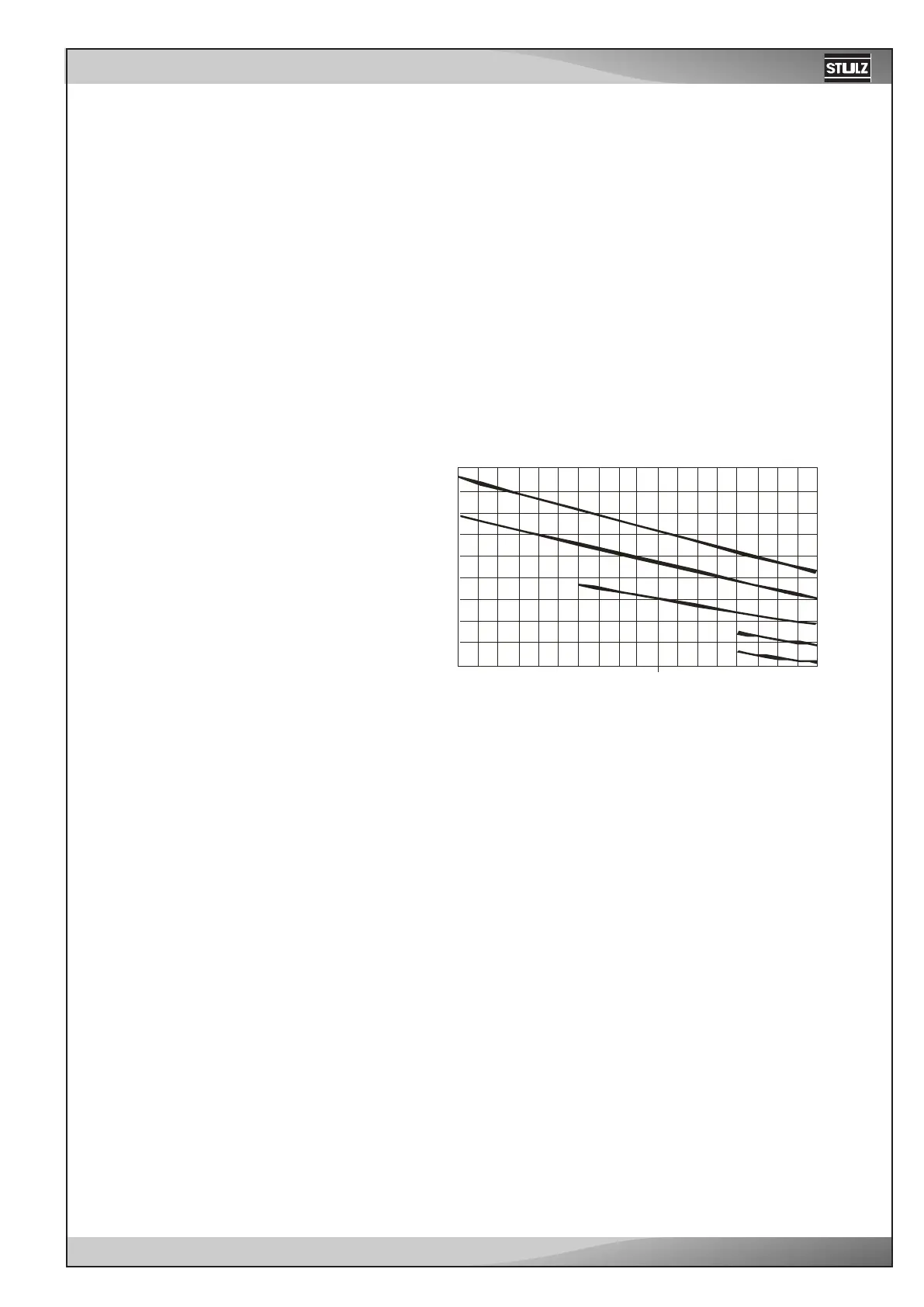

50%

40%

30%

20%

10%

-10 -8 -6 -4 -2 0 2 4 6 8

EN

External water circuit

To seal the water circuit you must connect the unit to a chilled water ring mains, which contains for the generation of

cold water either a chiller or a dry cooler or cooling tower. Moreover the water circuit must be provided with a pump

and an expansion tank with safety valve to convey the cooling water. If the water quality is insufficient, we recommend

the additional installation of a fine mesh strainer.

For an efficient protection against corrosion, the anti-freezing agent is mostly sufficient, which should be used if

the water temperature passes under 5°C or if the outside temperature is less than 0°C. We recommend to add the

following quantities of ethylenglycol (indicated as percentage of weight of the water quantity) :

water or outside air temperature ethylenglycol

from +5 to -5°C 10%

from -5 to -10°C 20%

from -10 to -15°C 28%

from -15 to -20°C 35%

from -20 to -25°C 40%

average chilled water temperature (°C)

correction coefficient for the pressure

drop in the water circuit when using

ethylenglycol

6.3.2 Water piping

Recommendation for Condenser Water Systems

On new or renovated condenser water systems, ensure that the external pipework is thoroughly flushed, to remove

construction debris and other particulate matter, before connecting to the new Stulz cooling units. A strainer should

be fitted at the unit inlet, to protect the heat exchangers from fouling and possible blockage.

The strainer should have a mesh size of 0.5 mm. Be aware that any fouling or blockage of the heat exchanger result

in a reduced water flow, loss of efficiency, possible damage to the heat exchanger and subsequent unit failure.

Loading...

Loading...