____________________________________________________________________________________

Operating Manual access/eco/peak/power/silent Page

10

2 O

PERATION

2.1. Placement of snowmaker:

It is advisable to put the snowmaker in an area which is as level as possible.

After the snowmaker is placed, it is fastened safely on the ground by the locking

jacks.

When transporting the snowmaker make sure that the horizontal swivel mechanism

is well fixed and cannot move by itself anymore.

For the wheel chassis and the construction on tripod with carrying device there is

the possibility to increase the width of the trail to 280 mm (at each side 140 mm)

According to the nature of the terrain this must be done before putting the machine

on the piste. Also take care of the maximum tyre pressure. If no other description

is on the tyre, there will be a maximum pressure of 2,7 bar.

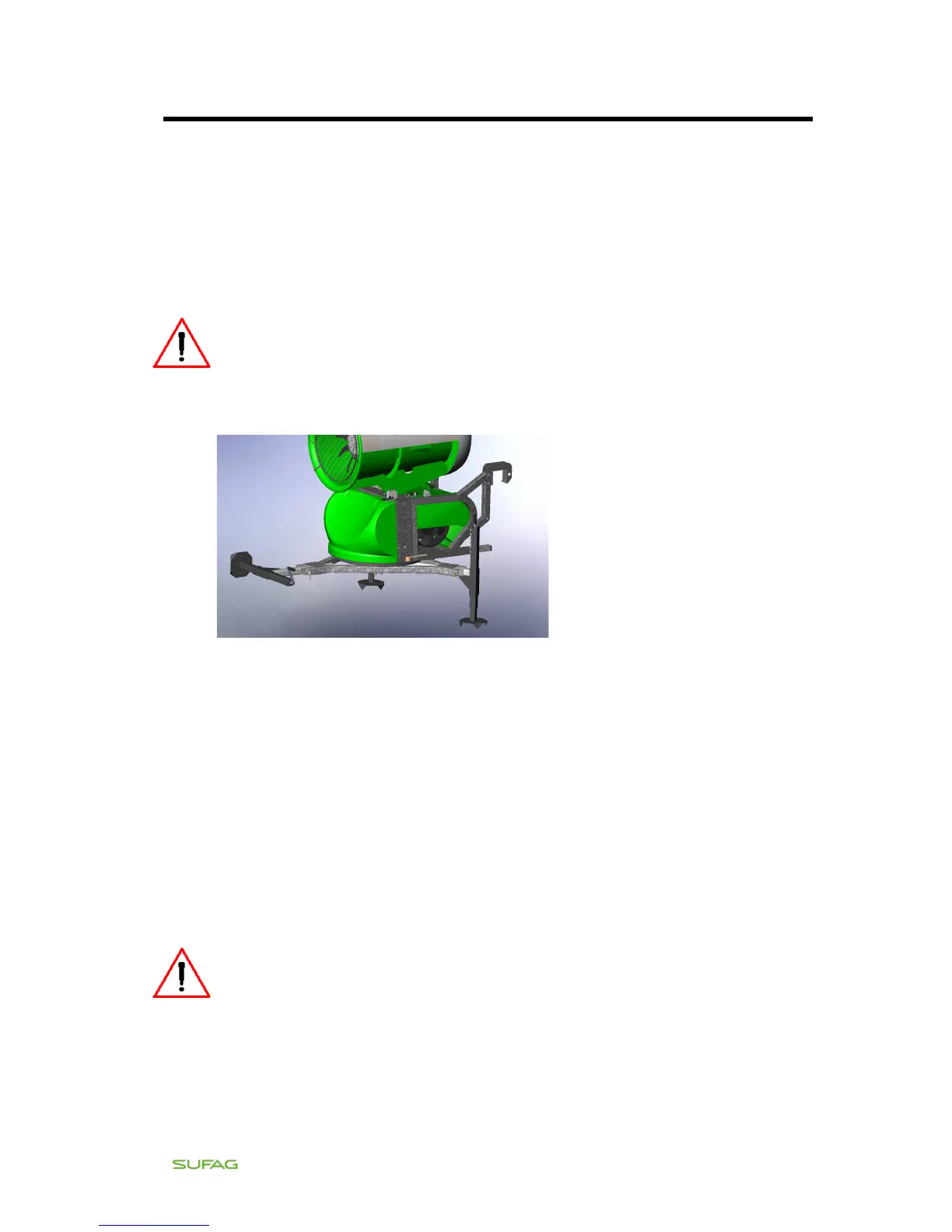

When transporting the machine on a tripod, we recommend rotating the front leg to

90°. See the picture below.

When transporting the machine, pay attention to the general security

regulations.

2.2. Water connection:

For the water connection there is a central turnable adapter with 2“ quick coupling

at the snowmaker.

The snowmaker is connected to the tapping station by a 2“ hose. For granting easy

handling, this hose should not be longer than 20m. In case of longer distance to the

tapping station, several hoses are used.

We recommend the approved snowmaking hose from SUFAG

®

.

2.3. Power connection:

IMPORTANT:

Check all electrical power connections inside the cabinet before taking the

snowmaker in use for the first time - they might have become loose during

transport. Check and tighten may only be done by authorized personnel.

The supply voltage of the snowmaker is 3x400/230 VAC (3L+N+PE) with a

tolerance of +5%/-10%. Therefore the admissible tension during operation ranges

from 378 VAC to 420 VAC.

Loading...

Loading...