Section 3

SPECIFICATIONS

9

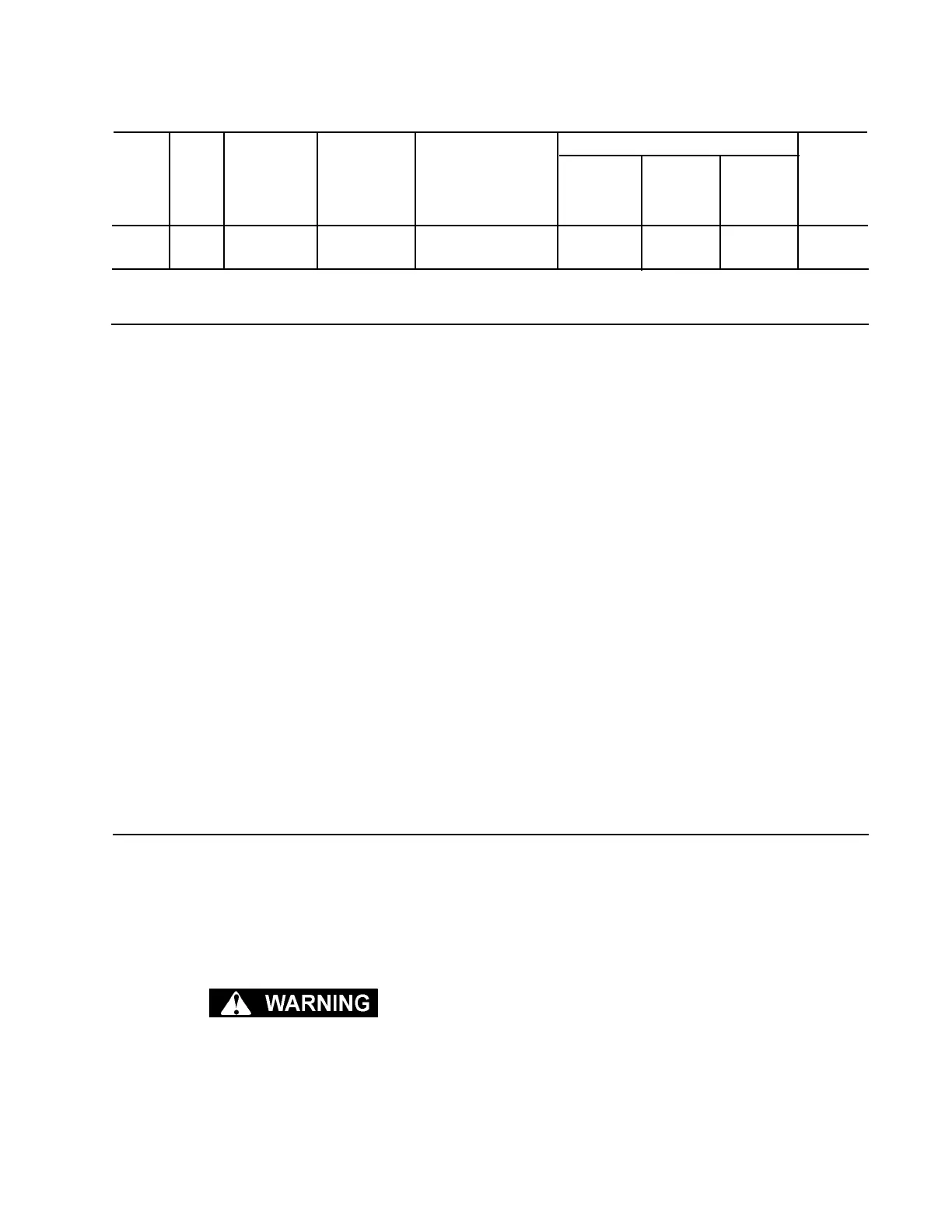

3.1 SPECIFICATIONS- ES-6 (I)

DIMENSIONS

50Hz KW Capacity Maximum dBA Length Width Height Weight

Model M

3

/Min Pressure with canopy/ mm mm mm kg

BAR without canopy

ES-6 4.1 .049 10 (II) 775 579 518 127

5.5HH

(I) For additional specifications, consult Figure 3-3 Dimensions in this Section.

(II) Note: dBA measurements unavailable at time of print. Consult Factory.

COMPRESSOR

Type: Single Stage Fluid Injected Screen Compressor

Minimum Full Load Operating Pressure: 4.1 bar

Maximum Full Load Operating Pressure: 9.5 bar

Bearing Type: Anti-friction

Cooling: Pressurized Fluid

Lubricant: See Lubrication Guide (Section 3.2)

Sump Capacity: 4.35 liters

MOTOR

Type: 4.1 kw

Synchronous Speed: 1500 RPM for 4.1 kw

Voltage: 380/415 3 Phase

Type: Totally Enclosed Air Over

Insulation Class: “F"

Maximum Ambient Temp.: 45ºC/ 113ºF

Shaft Diameter Fan: Nominal 5/8"

Key Size Fan: Nominal 3/16" x 3/16" x 1 1/4"

FLUID FILTER

Type: Spin on, Sullair Proprietary

Micron: 23 Microns Abs.

Internal Bypass Valve Set at 1.7 bar.

FLUID SEPARATOR ELEMENT

Type: Push In Cartridge, Sullair Proprietary

Efficiency at Maximum Capacity: 5PPM Maximum

3.2 COMPRESSOR LUBRICATION GUIDE

See Figure 3-1. For best value and longest uninter-

rupted service, the ES-6 compressor is factory filled

with Sullube, a long life lubricant, unless a different

lubricant is requested.

If, due to availability or other reasons, other fluids

are required, follow Table 3-1, Lubrication Guide.

“The Plastic Pipe Institute recommends against

the use of thermoplastic pipe to transport com-

pressed air or other compressed gases in

exposed above ground locations, e.g. in exposed

plant piping." (I)

Sullube should not be used with PVC piping sys-

tems. It may affect the bond at cemented joints.

Certain other plastic materials may also be affect-

ed.

(I) Plastic Pipe Institute, Recommendation B,

Adopted January 19, 1972.

Maintenance of all other components is still recom-

mended as indicated in the Operator's Manual.

For light-duty high-humidity service where con-

densed moisture and emulsification (mayonnaise)

may occur, the fluid change interval must be

reduced to 300 hours maximum. A non-detergent

fluid with rust, oxidation and foam inhibitors and

good water separation characteristics should be

used.

Loading...

Loading...