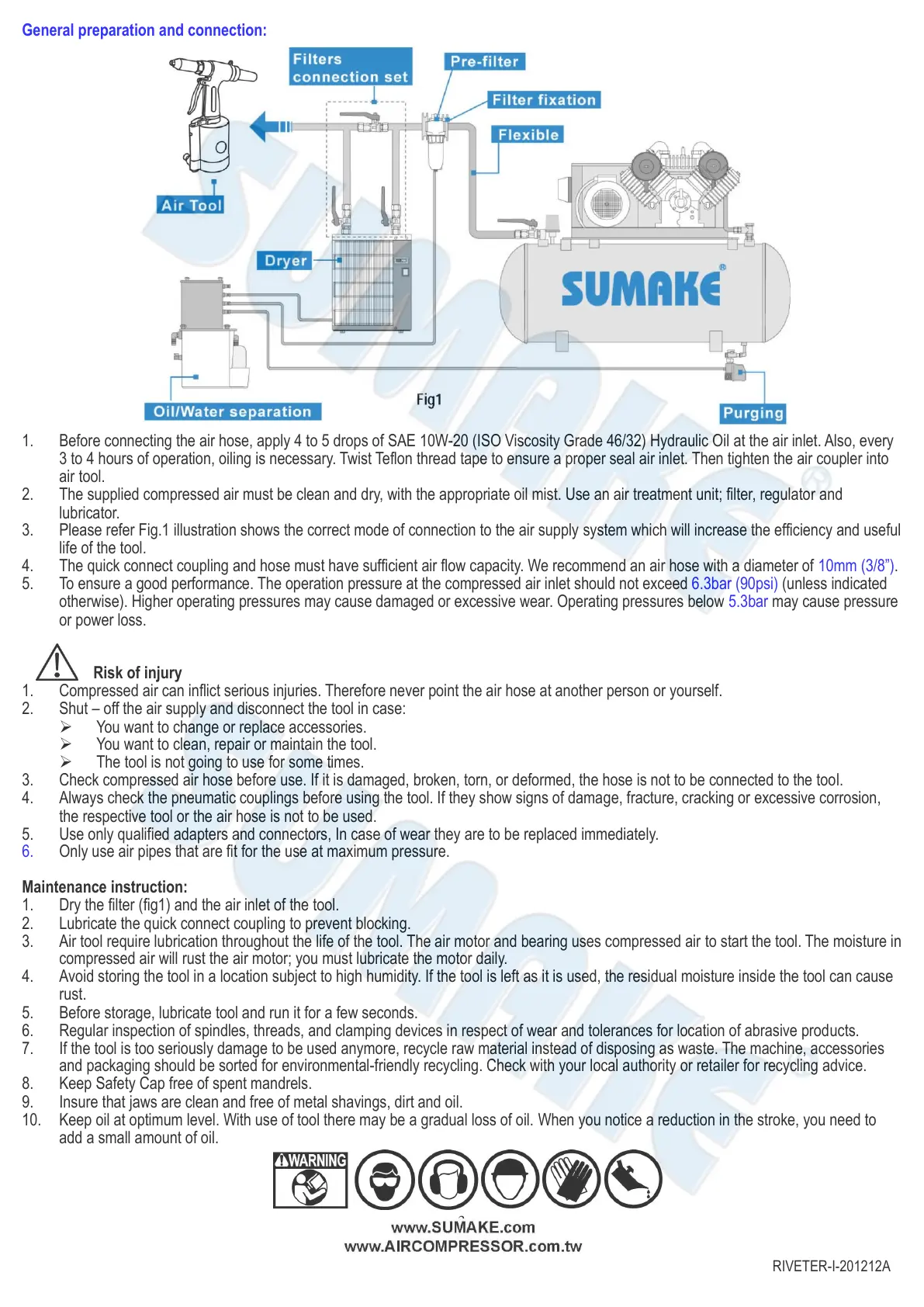

General preparation and connection:

1. Before connecting the air hose, apply 4 to 5 drops of SAE 10W-20 (ISO Viscosity Grade 46/32) Hydraulic Oil at the air inlet. Also, every

3 to 4 hours of operation, oiling is necessary. Twist Teflon thread tape to ensure a proper seal air inlet. Then tighten the air coupler into

air tool.

2. The supplied compressed air must be clean and dry, with the appropriate oil mist. Use an air treatment unit; filter, regulator and

lubricator.

3. Please refer Fig.1 illustration shows the correct mode of connection to the air supply system which will increase the efficiency and useful

life of the tool.

4. The quick connect coupling and hose must have sufficient air flow capacity. We recommend an air hose with a diameter of 10mm (3/8”).

5. To ensure a good performance. The operation pressure at the compressed air inlet should not exceed 6.3bar (90psi) (unless indicated

otherwise). Higher operating pressures may cause damaged or excessive wear. Operating pressures below 5.3bar may cause pressure

or power loss.

Risk of injury

1. Compressed air can inflict serious injuries. Therefore never point the air hose at another person or yourself.

2. Shut – off the air supply and disconnect the tool in case:

➢ You want to change or replace accessories.

➢ You want to clean, repair or maintain the tool.

➢ The tool is not going to use for some times.

3. Check compressed air hose before use. If it is damaged, broken, torn, or deformed, the hose is not to be connected to the tool.

4. Always check the pneumatic couplings before using the tool. If they show signs of damage, fracture, cracking or excessive corrosion,

the respective tool or the air hose is not to be used.

5. Use only qualified adapters and connectors, In case of wear they are to be replaced immediately.

6. Only use air pipes that are fit for the use at maximum pressure.

Maintenance instruction:

1. Dry the filter (fig1) and the air inlet of the tool.

2. Lubricate the quick connect coupling to prevent blocking.

3. Air tool require lubrication throughout the life of the tool. The air motor and bearing uses compressed air to start the tool. The moisture in

compressed air will rust the air motor; you must lubricate the motor daily.

4. Avoid storing the tool in a location subject to high humidity. If the tool is left as it is used, the residual moisture inside the tool can cause

rust.

5. Before storage, lubricate tool and run it for a few seconds.

6. Regular inspection of spindles, threads, and clamping devices in respect of wear and tolerances for location of abrasive products.

7. If the tool is too seriously damage to be used anymore, recycle raw material instead of disposing as waste. The machine, accessories

and packaging should be sorted for environmental-friendly recycling. Check with your local authority or retailer for recycling advice.

8. Keep Safety Cap free of spent mandrels.

9. Insure that jaws are clean and free of metal shavings, dirt and oil.

10. Keep oil at optimum level. With use of tool there may be a gradual loss of oil. When you notice a reduction in the stroke, you need to

add a small amount of oil.

Loading...

Loading...