SUNPOWER CORPORATION

Safety and Installation Instructions - Document 001-15497 Rev U

©September 2020 SunPower Corporation. All rights reserved. Specifications included in this manual are subject to change without notice.

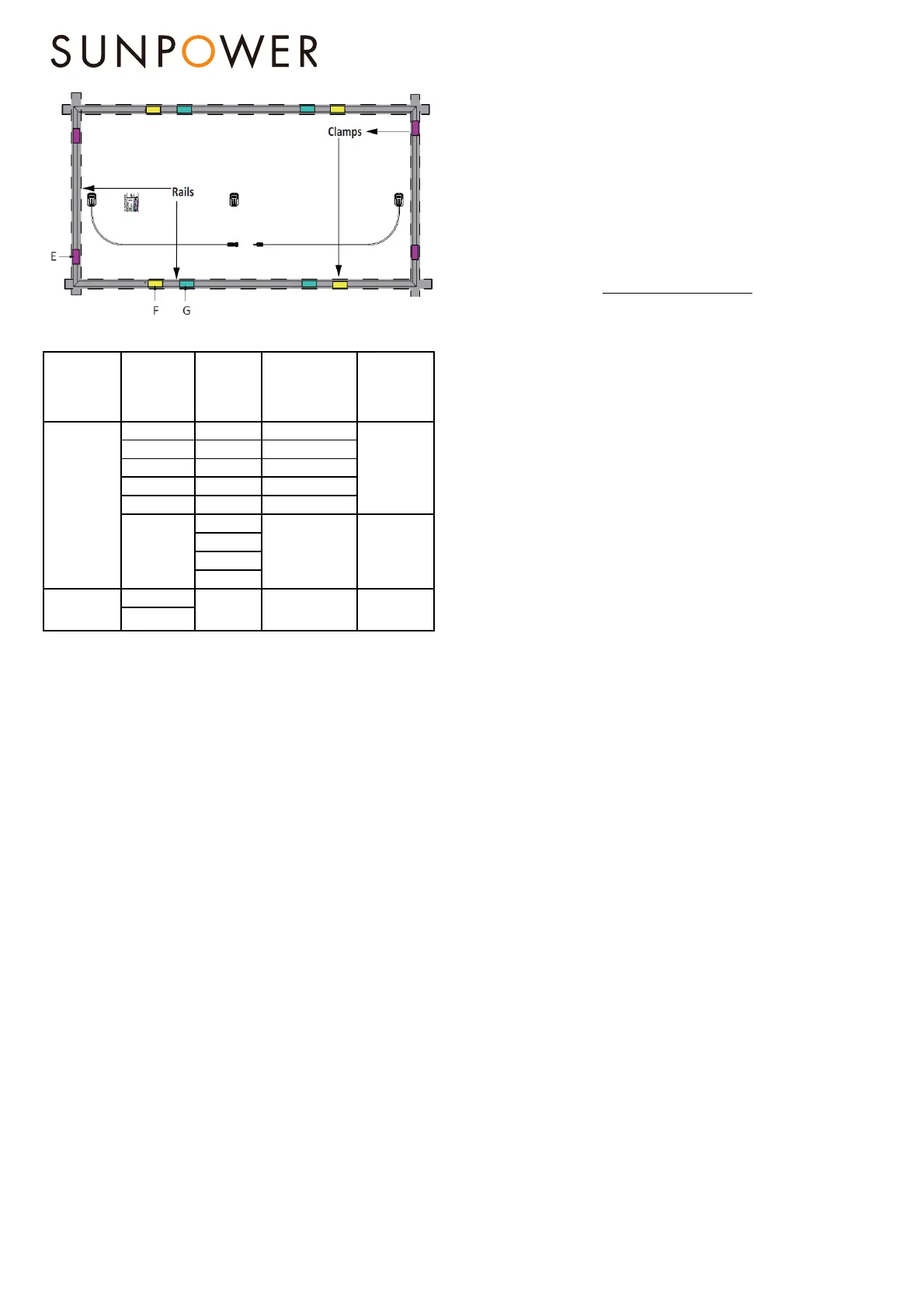

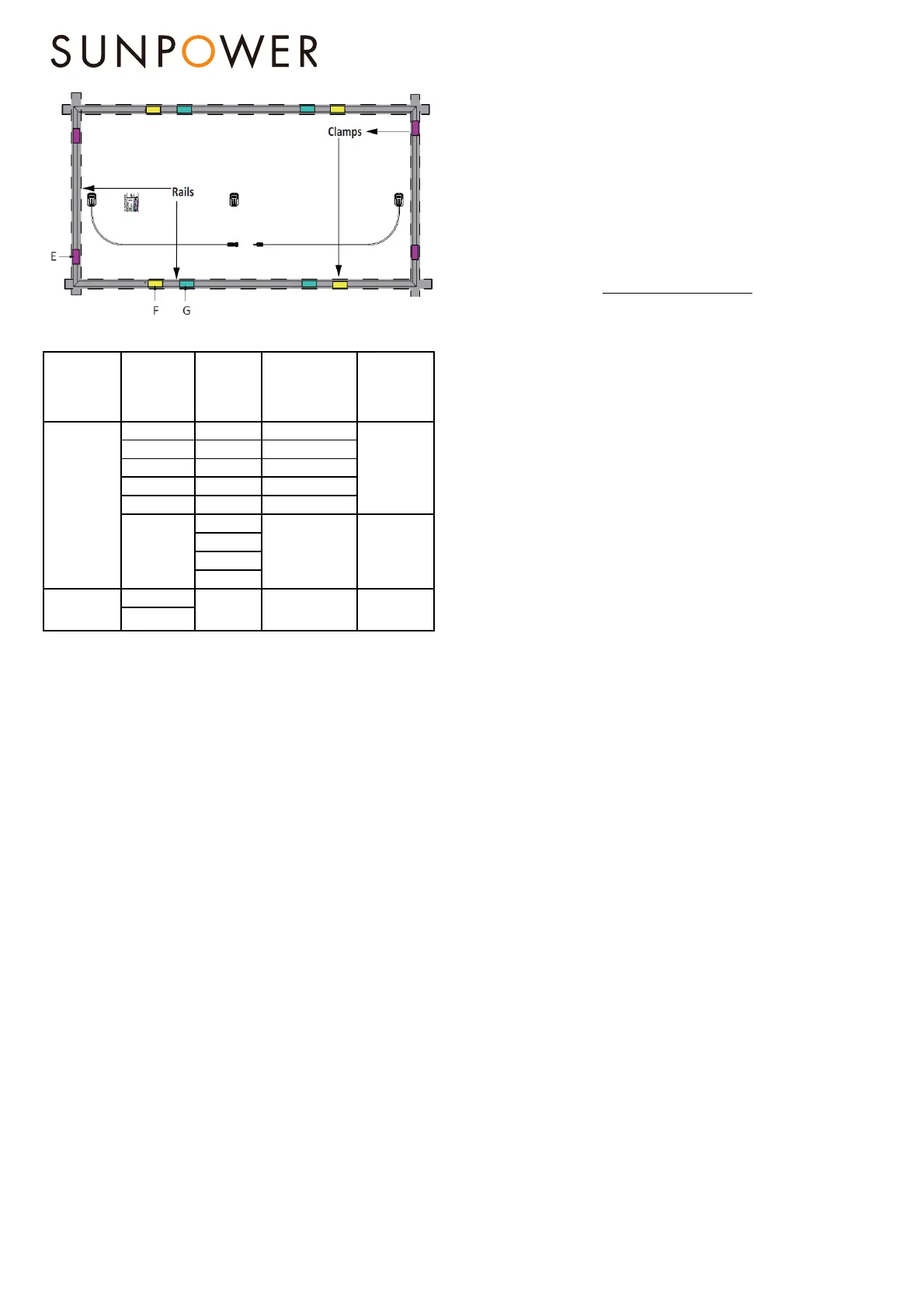

Table 1.4: Mounting Zone Load Ratings for Performance Modules

(Pending IEC Certification)

Applicable

Products

Mounting

Zone

Distance

from

corner

(mm)

Wind (up &

down) /

Snow(down)

(units in Pa)

3

Mounting

Method

P3 UPP

(2066 x 1160 x

35mm)

A 183-283 1600/2400

Clamp

B 466-566 1600/3600

4

D 783- 833 1600/1600

E 300-400 1600/1600

F 465-565 1600/2400

Frame

Holes

2

303

1600/3600 Bolt

504

603

803

P5 UPP

(2362 x 1092 x

35mm)

C

540-640 1600/3600 Clamp

G

2 Refer to Table 2 for different mounting hole locations

3 Safety Factor 1.5 included

4 IEC validated

5.3 Bifacial Gain

Various environmental and installation parameters affect bifacial

gain. Albedo is a measure of the amount of light reflected from the

ground surface. A higher albedo factor will increase irradiance on the

backside and result in higher bifacial gain of the module. The surface

conditions, month of the year, time of day, GHI and DNI both influence

the amount of incident rearside irradiance.

SunPower recommends to check with solar module mounting

hardware supplier in order to determine the Structure Shading factor

of your particular installation. The Structure Shading Factor varies

with racking system design, irradiance, albedo and height of module

installation above ground and has an overall impact on the rear side

irradiance mismatch.

The Rearside mismatch losses are proportional to the albedo, height

of the modules above ground and structure shading factor. The

irradiance non-uniformity on the rearside results in mismatch

generally as the albedo increases and installation height of the

modules are lower to the ground

5.4 Bifacial Electrical Considerations

The overall electrical bifacial gain is determined by the combination

of albedo, irradiance, shading losses from the rearside, rearside

mismatch and height of installation above ground. Please refer to

the SunPower datasheet for the electrical outputs with respect to

the overall bifacial gain. Please utilise a suitable performance

software package to simulate the overall bifacial gain.

5.5 Handling of Modules during Installation

Do not place modules face forward in direct contact with abrasive

surfaces like roofs, driveways, wooden pallets, railings, stucco walls,

etc…

The module front surface glass is sensitive to oils and abrasive

surfaces, which may lead to scratches and irregular soiling.

During storage, modules need to be protected from rain or any kinds

of liquids. Required storage temperature is between 10°C to 40°C in a

dry environment (humidity between 30 to 80%). Do not store modules

outdoor to avoid moisture and wet conditions.

Modules that feature antireflective coated glass are prone to visible

finger print marks if touched on the front glass surface. SunPower

recommends handing modules with anti-reflective glass with gloves

(no leather gloves) or limiting touching of the front surface. Any finger

print marks resulting from installation will naturally disappear over

time or can be reduced by following the washing guidelines in Section

6.0 below. Any module coverage (colored plastic tarps or similar)

during installation can lead to permanent front glass discoloration and

is not recommended. The use of vacuum lifting pads can cause

permanent marks on the front glass. Never lift or move the module

using the cables or the junction box under any-circumstances.

Shading incidence need to be avoided during PV system operation.

The system is not supposed to be energized until the mounting

scaffolding, fences or railing have been removed from the roof.

Systems should be disconnected in any cases of maintenance which

can cause shading (e.g. chimney sweeping, any roof maintenance,

antenna/dish installations, etc).

6.0 Maintenance

SunPower recommends visual inspection on a regular basis of all

modules for safe electrical connections, sound mechanical

connection, and freedom from corrosion. This visual inspection should

be performed by trained personnel. The standard frequency is once a

year according to environmental conditions Periodic cleaning of

modules is recommended but is not required. Periodic cleaning has

resulted in improved performance levels, especially in regions with

low levels of annual precipitation (less than 46,3cm (18,25 inches)).

Consult your dealer or supplier about recommended cleaning

schedules for your area.

To clean a module, wash with potable, non-heated, water. Normal

water pressure is more than adequate, but pressurized water up to

100 bar (min.50 cm distance) may be used. SunPower recommends

using a large hosepipe and not to perform cleaning at high outside

temperatures. Fingerprints, stains, or accumulations of dirt on the

front surface may be removed as follows: first rinse off area and let

soak for a short period of time (5 mins). Re-wet and use a soft sponge

or seamless cloth to wipe glass surface in a circular motion.

Fingerprints typically can be removed with a soft cloth or sponge and

water after wetting. Do not use harsh cleaning materials such as

scouring powder, steel wool, scrapers, blades, or other sharp

instruments to clean the glass surface of the module. Use of such

materials or cleaning without consultation will invalidate the product

warranty. As dry cleaning is also risky for Anti-Reflective (AR) coated

module surface, spinning brush is not recommended for module

cleaning.

Loading...

Loading...