144

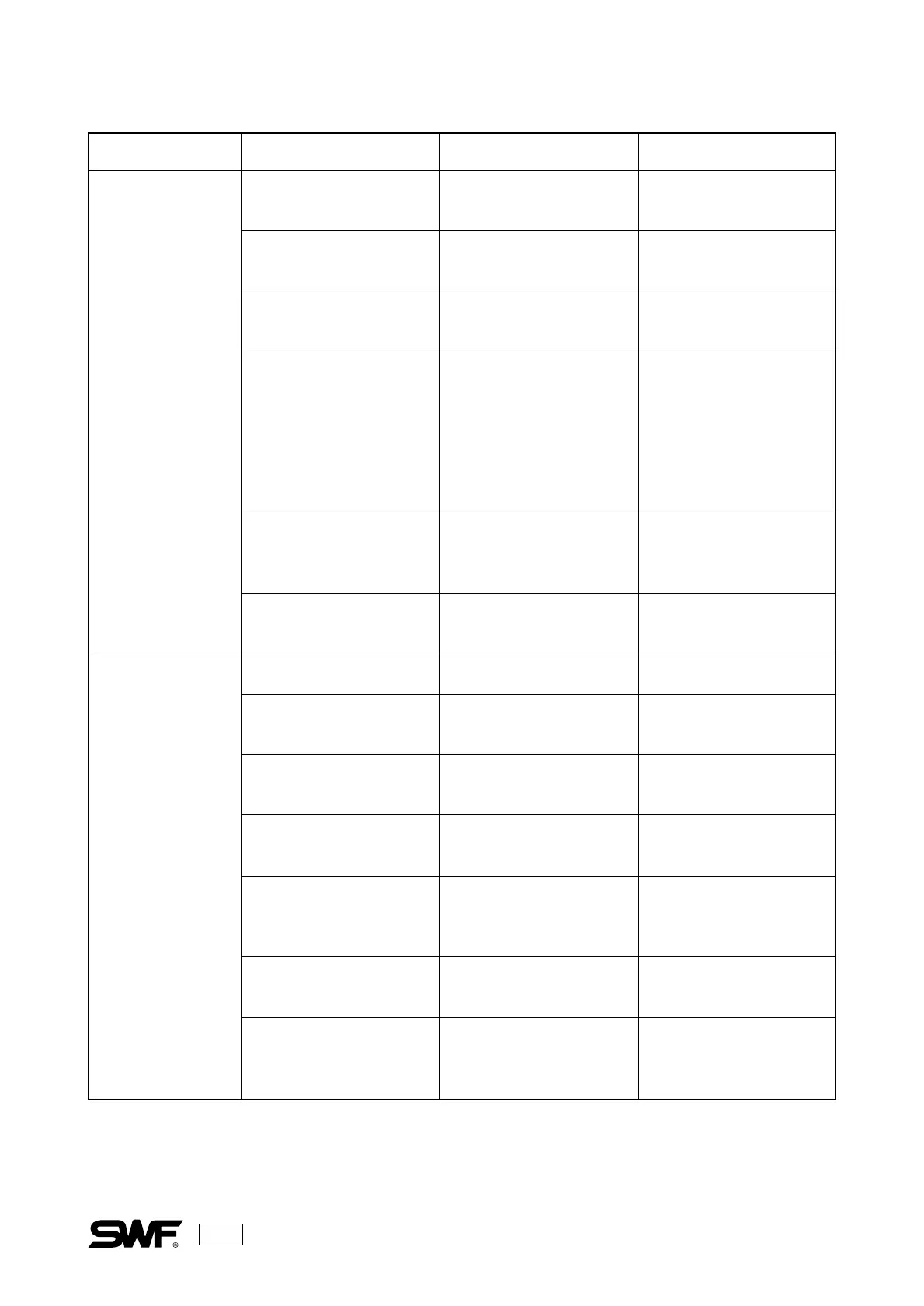

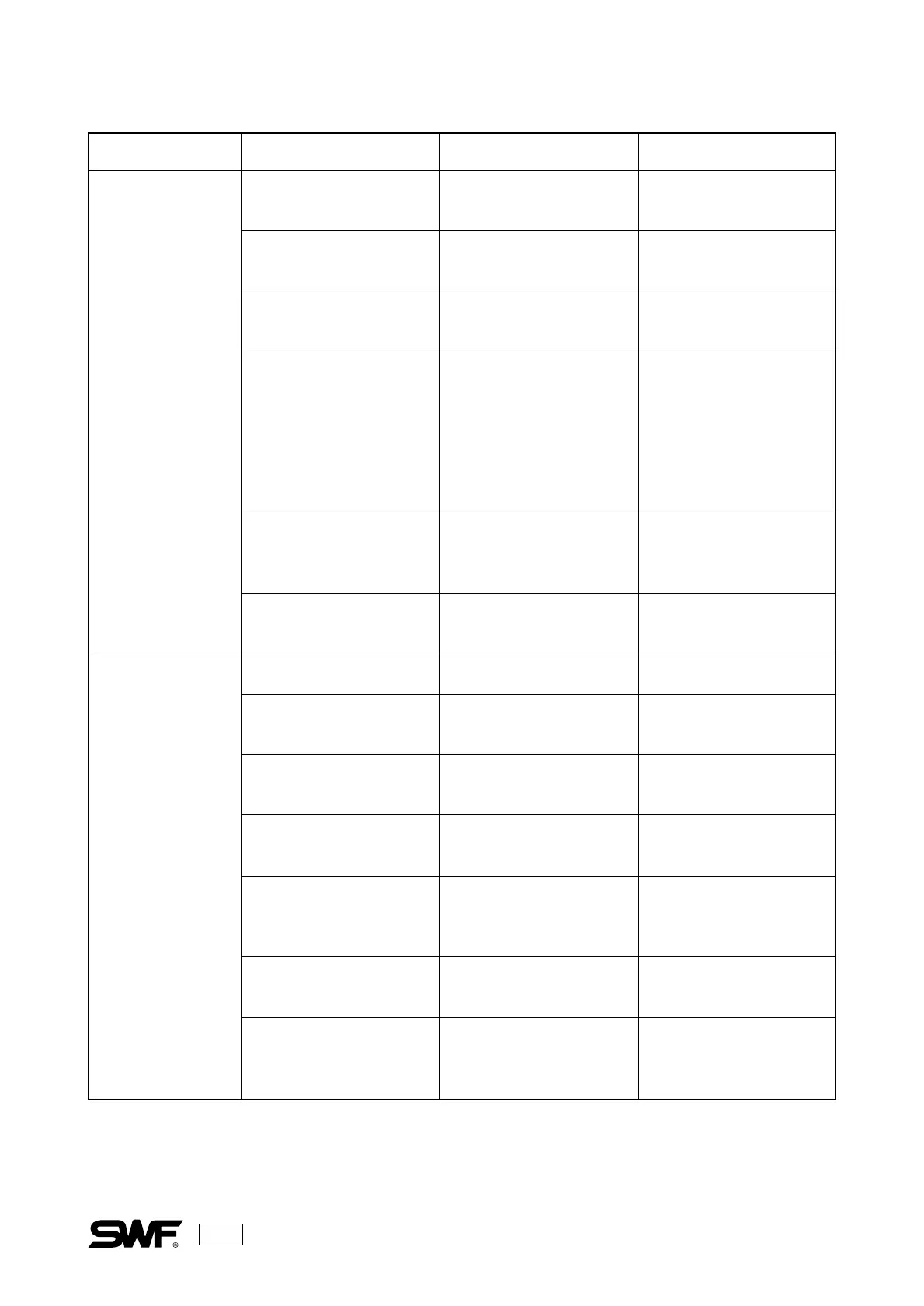

PROBLEM TIP or PAGEREMEDYPROBABLE CAUSE

Frequent thread

breaks.

Skipped stitches.

Oil the raceway of the hook

assembly.

Adjust the timing.

Readjust lower dead stop on

the needle bar.

Check the presser foot

where the thread passes, the

needle hole on the throat

plate, the thread guides on

the sewing head and the

tension discs for nicks and

burrs.

Correct hooped material so

it is held taut for stitching.

Adjust the height of the

presser foot.

Change the needle.

Change the needle or use a

different thread.

Install needle correctly.

Readjust the timing between

the needle and hook.

Adjust the distance between

the needle and the hook

point.

Readjust the lower dead

stop on the needle.

Use crocus cloth to smooth

out the point of the hook or

replace the hook.

Not enough oil in the hook.

Timing between the needle

and the hook is incorrect.

Incorrect lower dead stop

on the needle bar.

Thread is damaged on its

way through the thread

path.

Too much movement in the

material in the embroidery

hoop.

Incorrect presser foot

height.

The needle is bent.

Incorrect needle size for

thread.

The needle is installed

incorrectly.

Timing between the needle

and the hook is incorrect.

Too much distance between

the groove of the needle and

the point of the hook.

Incorrect lower dead stop

on needle.

Damage to the point of the

hook.

Loading...

Loading...