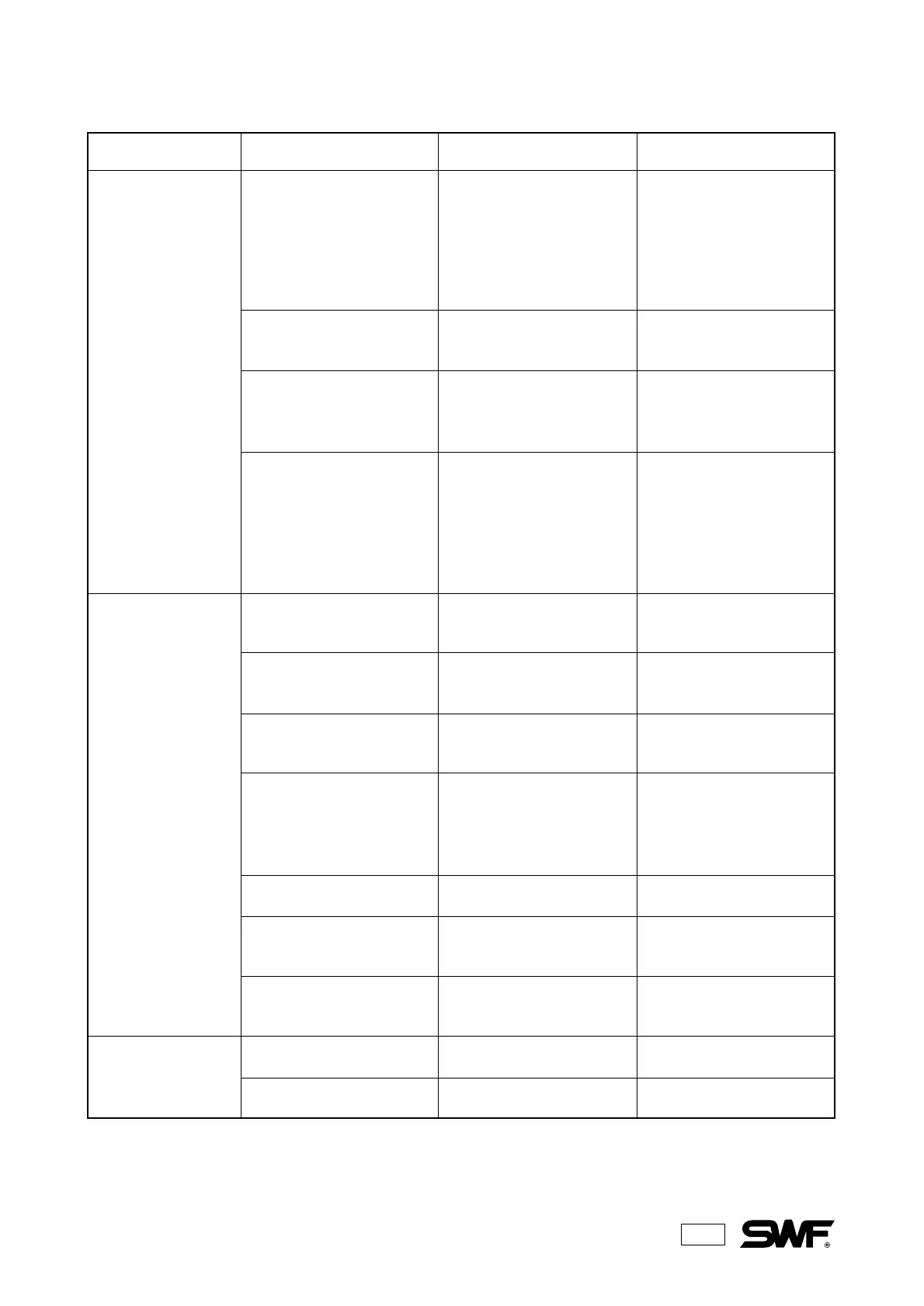

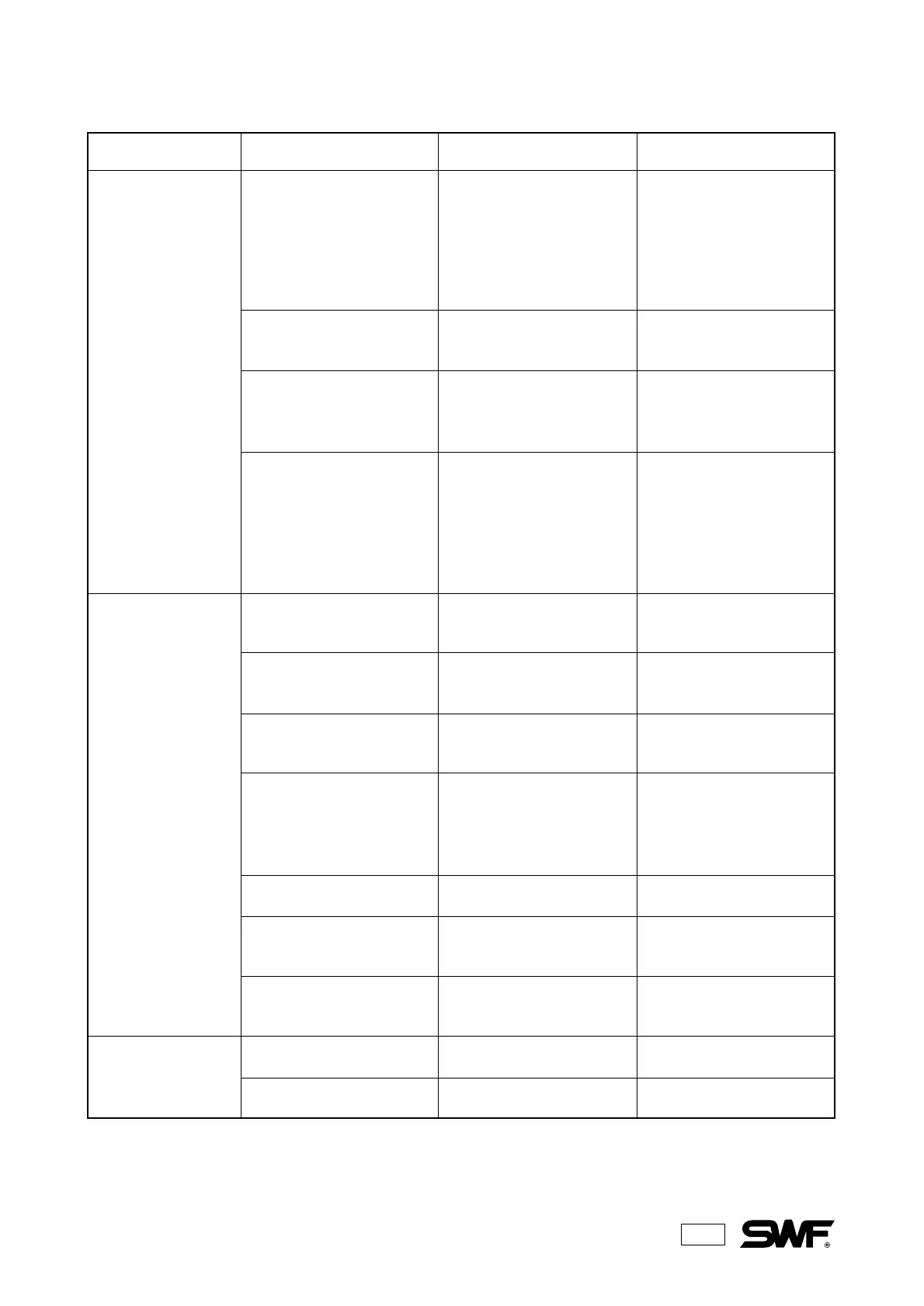

145

PROBLEM TIP or PAGEREMEDYPROBABLE CAUSE

Skipped stitches.

Stitches pull out of

material.

Needle Breaks.

Readjust the upper and

lower thread tension.

If the problem is only on the

lower thread. Replace the

bobbin or the bobbin case.

Select the proper thread for

the job.

Adjust the take-up spring

stroke and tension.

Replace the tension spring

on the presser foot.

Adjust upper thread tension.

Clean discs of the pre-

and main tensioners.

Adjust bobbin thread

tension.

Clean the bobbin case,

being careful to clean any

lint from under the

adjustment spring.

Use good quality thread.

Adjust the timing.

Oil the raceway of the hook

assembly.

Replace the needle.

Buy good needle.

Frequent stops in the supply

of the upper and lower

thread.

The thread is too thick or

has too much stretch.

Take-up spring is adjusted

incorrectly resulting in

tension that is too tight.

Fabric moves in the hoop

when the needle enters or

exits because the tension of

the presser foot is too weak

or the tension spring on the

presser foot is damaged.

Upper thread tension is too

loose.

Upper thread is dirty which

is affecting the tension.

Lower thread tension is too

loose.

Uneven bobbin tension.

Thread is too thick.

Incorrect timing between

the needle and the hook.

Not enough oil in the

raceway of the hook.

Needle is bent.

Needle is poor quality.

Loading...

Loading...