RETROREFLECTIVE TYPE SEN-

SOR WITH POLARIZING FILTERS

(CX-491š)

8

٨ As light is polarized by a transparent film or mem-

brane, CX-491غ may not detect an object covered

or wrapped by transparent film. In that case, take

the following measures.

<Example of sensing objects>

Can wrapped by clear film

Aluminum sheet covered by plastic film

Gold or silver color (glossy) labels or wrapping

paper

<Measures>

Tilt the sensor with respect to the sensing object

upon fitting.

Reduce the sensitivity.

Increase the distance between the sensor and the

sensing object.

How to mount

SLIT MASK (OPTIONAL)

(Exclusively for thru-beam type sensor)

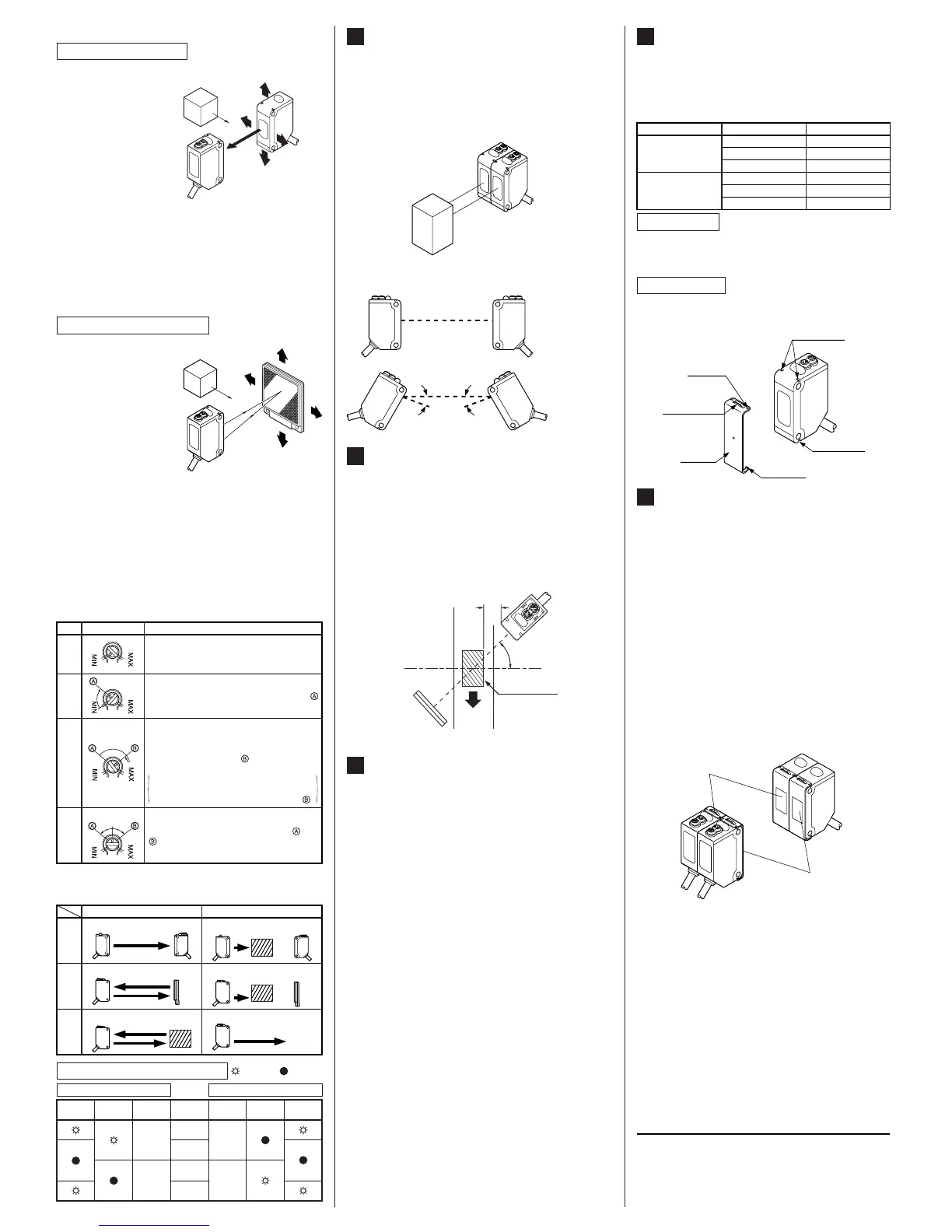

9

٨ With the slit mask (OS-CX-غ), the sensor can

detect a small object.

However, the sensing range is reduced when

the slit mask is mounted.

Ԙ

ԙ

Insert the fixing hook into the fixing groove.

Then, pressing the slit mask against the main

unit, insert the fixing tab into the fixing groove.

Ԙ

ԙ

Insert a screwdriver into the removing tab.

Pull forward while lifting the removing tab.

How to remove

Type Model No. Slit size

Round slit mask

OS-CX-05 Ǿ0.5mm

OS-CX-1 Ǿ1mm

OS-CX-2 Ǿ2mm

Rectangular slit

mask

OS-CX-05g6 0.56mm

OS-CX-1g6 16mm

OS-CX-2g6 26mm

Fixing groove

Fixing tab

Removing tab

Slit mask

Fixing groove

Fixing hook

INTERFERENCE PREVEN-

TION FILTER (OPTIONAL)

(Exclusively for CX-411š)

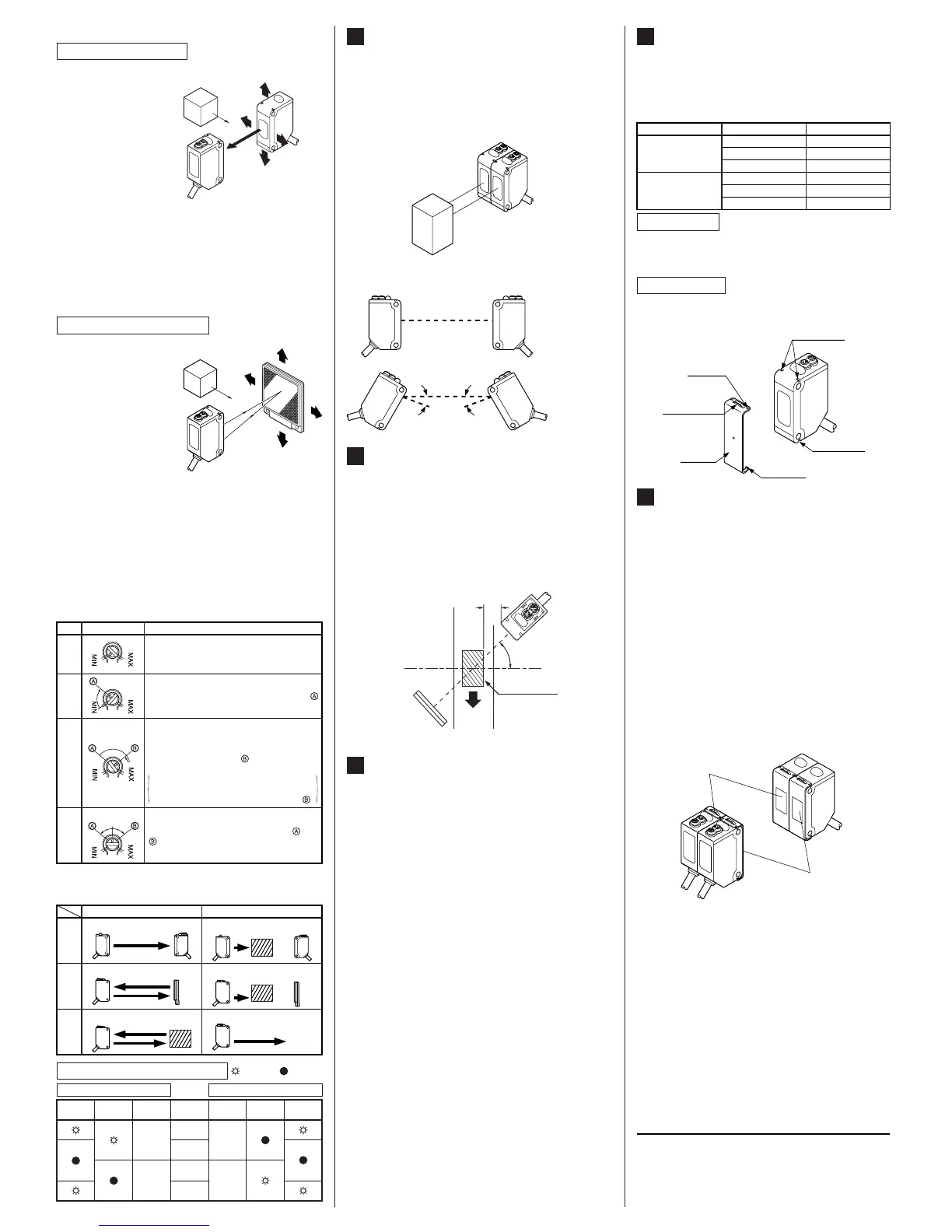

10

٨

٨

٨

By mounting the interference prevention filters

(PF-CX4-غ), two sets of the CX-411غ can be

mounted close together.

However, the sensing range is reduced when

the interference prevention filter is mounted.

The filters can be mounted by the same method

as for the slit masks.

Since there are two types of the interference

prevention filter, the two sets of sensors should

be fitted with different types of interference pre-

vention filters, as shown in the figure below.

The interference prevention does not work even

if the filters are mounted for emitters only, re-

ceivers only or the same model No. of the inter-

ference prevention filters are mounted on both

the sets of the sensor.

Fitted with

PF-CX4-H

Fitted with

PF-CX4-V

٨ Sensitivity adjustment

Note: Use the 'minus' adjusting screwdriver (please arrange sepa-

rately) to turn the adjuster slowly. Turning with excessive

strength will cause damage to the adjuster.

Ԙ

ԙ

Ԛ

ԛ

Turn the sensitivity adjuster fully counter-

clockwise to the minimum sensitivity posi-

tion, MIN.

In the light received condition, turn the sensitivity

adjuster slowly clockwise and confirm the point

where the sensor enters the 'Light' state operation.

In the dark condition, turn the sensitivity ad-

juster further clockwise until the sensor en-

ters the 'Light' state operation and then bring

it back to confirm point where the sensor

just returns to the 'Dark' state operation.

If the sensor does not enter the 'Light' state

operation even when the sensitivity adjuster is

turned fully clockwise, the position is point .

The position at the middle of points and

is the optimum sensing position.

Step

Sensitivity adjuster

Description

Optimum position

Diffuse

reflective

Thru-beam

Retroreflective

Light received condition Dark condition

Emitter Receiver

Sensing

object

Sensor

Sensor Reflector

Emitter Receiver

Sensing

object

Sensor

Sensing

object

Sensor Reflector

Relation between output and indicators

In case of Light-ON In case of Dark-ON

: Lights up,

: Turns off

Stable light

receiving

Stable dark

receiving

Unstable light

receiving

Unstable dark

receiving

Stability

indicator

Operation

indicator

Output

ON OFF

OFF ON

Stability

indicator

Operation

indicator

Output

Sensing

condition

LONG SENSING RANGE RET-

ROREFLECTIVE TYPE SENSOR

(CX-493š)

7

٨ Please take care of the following points when

detecting materials having a gloss.

Ԙ

ԙ

Make 'L', shown in the diagram, sufficiently

long.

Install at an angle of 10 to 30 degrees to the

sensing object.

* CX-491غ do not need the above adjustment.

L

10 to 30q

Sensing

object

Reflector

Glossy surface

SUNX Limited

٨ Beam alignment

Ԙ

ԙ

Ԛ

ԛ

Ԝ

ԝ

Set the operation mode switch to the Light-ON mode

position (L side).

Placing the emitter

and the receiver face

to face along a straight

line, move the emitter

in the up, down, left

and right directions, in

order to determine the

range of the light re-

ceived condition with

the help of the operation indicator (orange).

Then, set

the emitter at the center of this range.

Similarly, adjust for up, down, left and right angular

movement of the emitter.

Further, perform the angular adjustment for the re-

ceiver also.

Check that the stability indicator (green) lights up.

Choose the operation mode, Light-ON or Dark-ON, as

per your requirement, with the operation mode switch.

Sensing object

Emitter

Receiver

Thru-beam type sensor

Ԙ

ԙ

Ԛ

ԛ

Ԝ

ԝ

Set the operation mode switch to the Light-ON mode

position (L side).

Placing the sensor

and the reflector

face to face along a

straight line, move

the reflector in the

up, down, left and

right directions, in

order to determine

the range of the

light received condition with the help of

the operation indicator (orange). Then, set the re-

flector at the center of this range.

Similarly, adjust for up, down, left and right angular

movement of the reflector.

Further, perform the angular adjustment for the

sensor also.

Check that the stability indicator (green) lights up.

Choose the operation mode, Light-ON or Dark-ON, as

per your requirement, with the operation mode switch.

Retroreflective type sensor

Reflector

Sensor

AUTOMATIC INTERFERENCE

PREVENTION FUNCTION

(Excluding thru-beam type sensor)

6

Note: If two diffuse reflective type sensor are mounted facing each

other, they should be angled so as not to receive the beam

from the opposing sensor or to detect its front face.

٨ Retroreflective type sensor and diffuse reflective

type sensor incorporate this function. Up to two

sets of sensor can be mounted closely.

(Thru-beam type sensor does not have this function.)

Close mounting of two sensors

No good

ǰ ǰ

Good

Loading...

Loading...