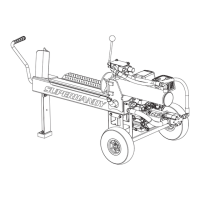

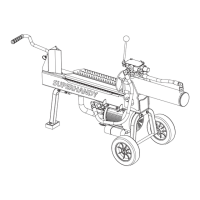

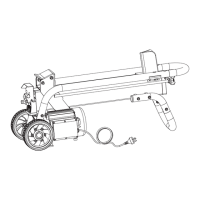

The SuperHandy 20 TON Gas Powered Hydraulic Log Splitter is a robust and efficient machine designed for splitting logs. Its primary function is to convert hydraulic pressure into linear force, allowing users to split wood with ease and speed. The log splitter is powered by a 7.0HP/209CC 4-stroke, air-cooled engine, ensuring reliable performance for various wood-splitting tasks.

Usage Features:

Operating the SuperHandy log splitter requires careful attention to safety guidelines and proper procedures to ensure efficient and safe use. Before starting, users must thoroughly read and understand the operator's manual. The machine is designed for outdoor use only, in well-ventilated areas, to prevent exposure to toxic engine exhaust, which contains carbon monoxide. It is crucial to keep all objects and other individuals at least 10 feet (3m) away from the machine during operation.

When loading logs, users should always hold them on the sides, keeping hands and feet clear of the cylinder, wedge, and partially split logs. The log splitter is specifically designed to split wood with the grain; attempting to split logs against the grain or perpendicular to it is strictly prohibited and can be dangerous. Only one log should be split at a time, unless the ram is fully retracted and a second log is needed to complete the splitting of the first. If logs are not squared, the longest portion should be rotated down, and the most squared end placed against the ram.

The control valve handle allows users to control the movement of the thrust plate. The detent (auto-return) feature of the control valve simplifies operation. Users should only use their hand to operate the controls and never kick the handle with their feet. The machine should always be operated on a level surface, with tires blocked and the support leg secured to prevent unintended movement. It is not intended to be towed behind a vehicle; its handle and wheels are solely for moving the log splitter by hand on the work site. Any modifications to allow towing by other means will void all warranties.

Before starting the engine, ensure the gasoline cap, air filter, spark plug, fuel lines, and exhaust system are properly in place. Any spilled gasoline must be allowed to evaporate fully. The engine should be turned off and allowed to cool for at least two minutes before removing the gasoline cap or refueling. Refueling should only occur outdoors in a well-ventilated area, using an approved container. Overfilling the gasoline tank should be avoided, and gasoline must be kept away from sparks, open flames, pilot lights, heat, and other ignition sources. Smoking while fueling is strictly forbidden.

The log splitter is equipped with a low oil shut-off feature, which helps protect the engine. If the engine starts to run roughly or shuts down during operation, common issues like low oil level, incorrect choke position, or loose spark plug wires should be checked. If the wedge movement is slow or erratic, it may indicate air in the hydraulic oil system, which can be purged by extending and retracting the cylinder several times until motion is smooth.

Maintenance Features:

Regular maintenance is essential for the longevity and safe operation of the SuperHandy log splitter. Before any repair or adjustment, the power source must be shut off. The engine cylinder, cylinder head fins, recoil starter cover, and muffler areas should be regularly cleaned of debris. If the engine is equipped with a spark arrestor muffler, it should be cleaned and inspected regularly according to the manufacturer's service instructions, and replaced if damaged.

The hydraulic oil level should be checked regularly using the dipstick. The dipstick should be inserted into the fill neck until it stops, then removed and read without threading it in. If the hydraulic oil level is low, AW32 or AW46 hydraulic oil should be added. The hydraulic system should be inspected regularly for leaks, as high-pressure hydraulic fluid can cause severe injury. Leaks can be detected by passing cardboard or wood over suspected areas, looking for discoloration. If injured by escaping fluid, immediate medical attention is necessary.

All nuts and bolts should be checked regularly to ensure they are tight, as engine motor vibration can cause them to loosen over time. This ensures the equipment remains in safe working condition. The log splitter should not be stored indoors with fuel in the tank, as fumes can reach open flames or sparks. It should be allowed to cool before storing in any enclosure. Debris should be cleared from movable parts only when the power source is shut off.

For safety reasons, hydraulic oil, engine oil, and fuel are not included in the package and must be added by the user before initial operation. If the cylinder thrust is insufficient, hydraulic oil may need to be added. The engine oil level should also be checked using the engine oil fill cap/dipstick, and SAE 15W-40 is recommended for general use, with other viscosities suitable for specific environmental temperatures. If using ethanol-blended fuel, a fuel stabilizer mixed to manufacturer specifications is recommended.

The log splitter should be stored away from sparks, open flames, pilot lights, heat, and other ignition sources. It should not be stored near furnaces, water heaters, or any other appliances that produce heat or have automatic ignitions. When transporting or servicing, ensure the fuel valve is in the OFF position, the gasoline tank is empty, and the spark plug wire is disconnected.