MG & SG Series Boilers – Installation and Service Manual

15

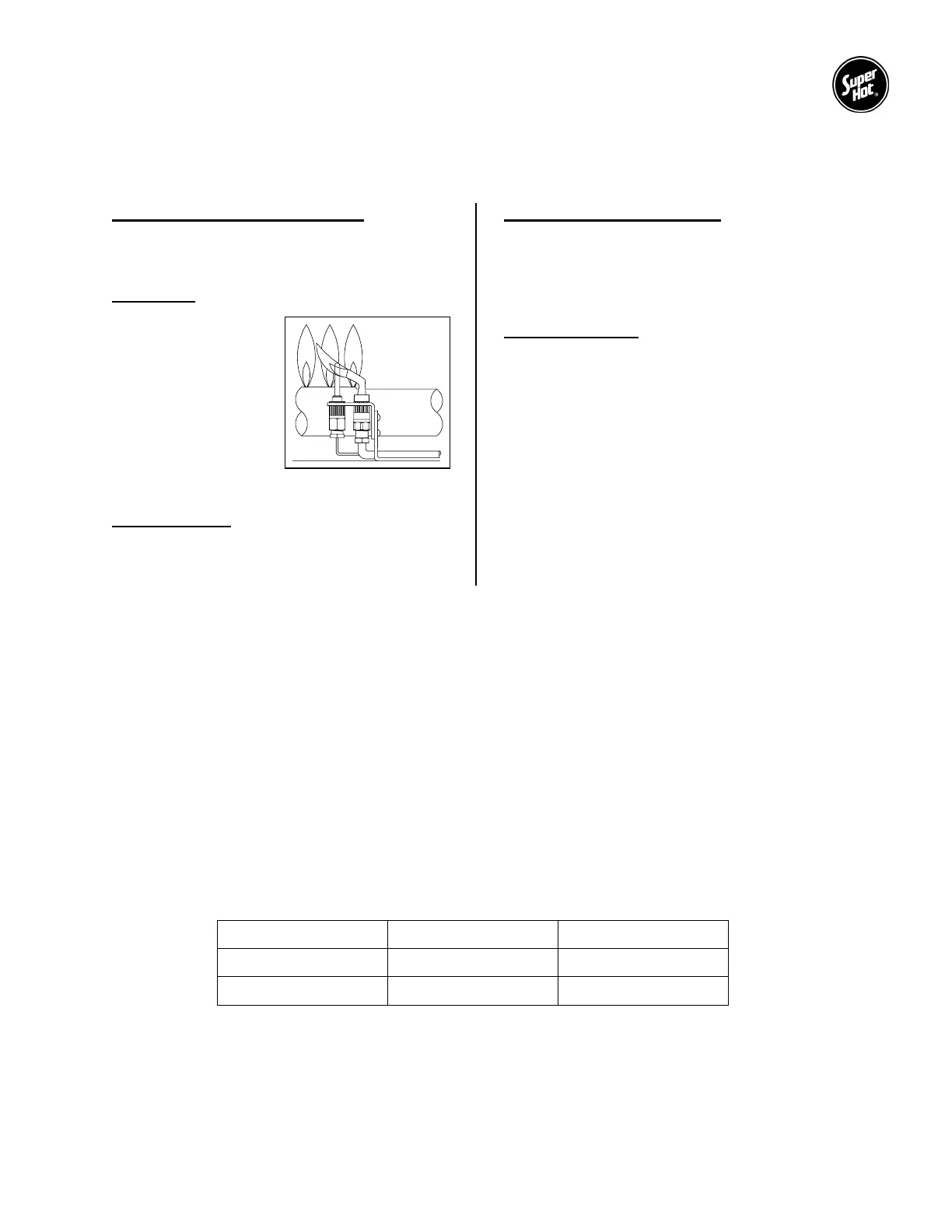

FIGURE 2 - PILOT FLAME

ADJUSTMENT

3.3 CHECK BURNER SYSTEM

To maintain safe and efficient operation, examine the burner system regularly through the inspection hole

near the pilot tube.

Check condition of burner system

It is possible for parts of the burners system to

become plugged, cracked, eroded and/or

dislodged resulting in unsafe operation.

Pilot Flame

Remove cap screw

cover on gas valve,

then adjust gas flow to

the point where the

thermocouple tip or

sensor rod is

completely enveloped

by the flame (Figure 2),

but not necessarily

glowing red. Replace

and tighten cap.

Check for lifting

Flames should not lift excessively from the

burner ports. The flames may lift slightly during

ignition or when the burners are cold.

Check ignition and extinction

Ignition should flow quickly and smoothly across

all the burners. Popping noises or explosions

from the burners during ignition, extinction or

normal burner operation indicates the need for

service.

Check flame color

An extremely yellow flame, as seen on a burning

candle or match, is an indication of incomplete

combustion and is usually accompanied by the

formation of soot and carbon monoxide (carbon

monoxide is a lethal, colorless and odorless

gas). If soot is allowed to accumulate, it will

partially restrict free passage of products of

combustion to the flue. Under typically

operating conditions, the flame should have a

distinct bright blue inner cone and a blue/orange

outer cone.

If any of the above problems are observed or the burner system does not operate properly,

immediately take corrective measures.

3.4 AQUASTAT ADJUSTMENT

The factory mounted aquastat controls main burner firing by sensing outlet water temperature. To set the

temperature of this control, adjust the dial until indicator points to the temperature (setpoint) at which the

gas valve will close. The gas valve will open at setpoint less the differential. The automatic reset safety

high-limit aquastat is either fixed or, if adjustable, should be set a minimum of 20°F (10°C) above the

setting of the aquastat.

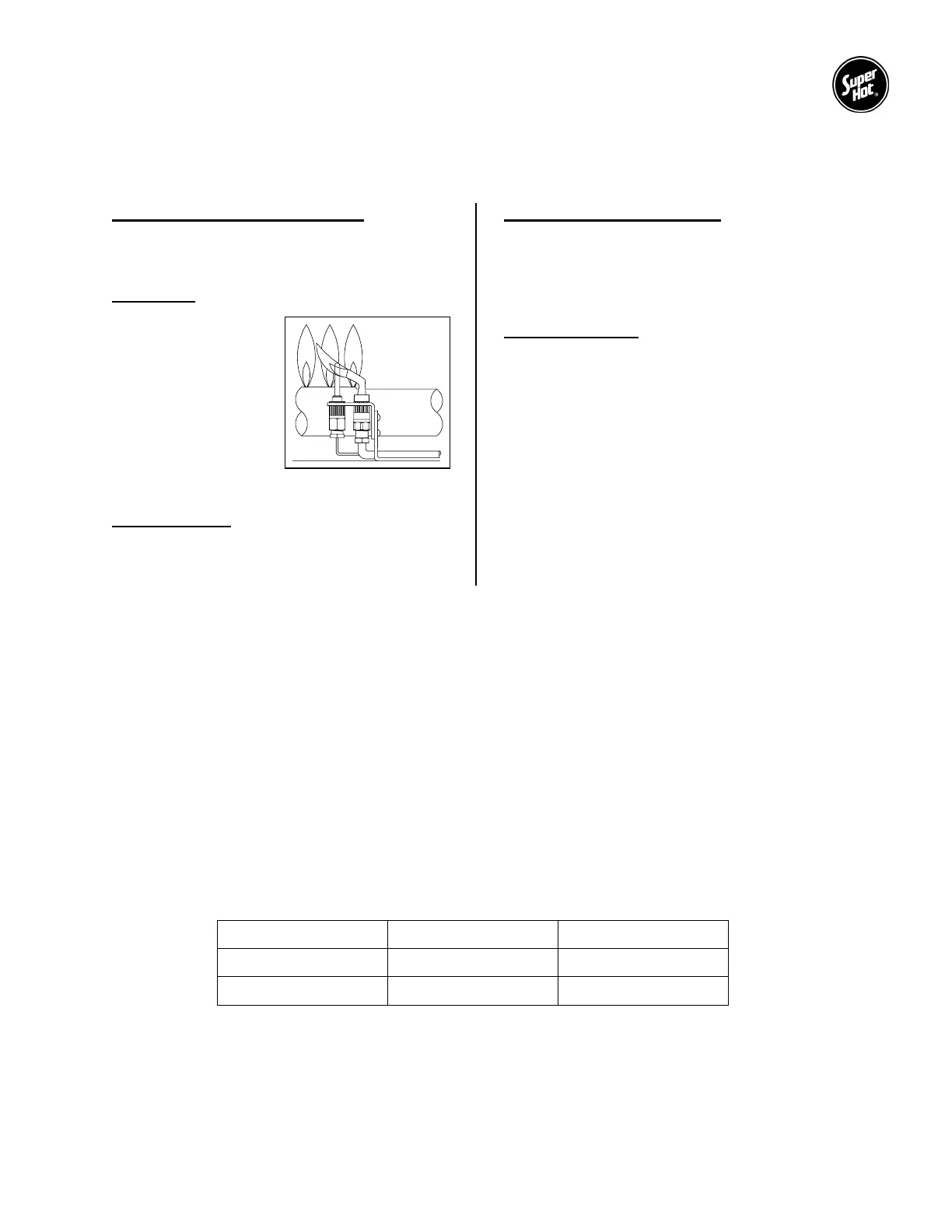

3.5 GAS MANIFOLD PRESSURE

The designated manifold pressures are as shown in the table below. A 1/8” NPT tapping is provided on

the manifold or gas valve for connecting a manometer to check this pressure. Both natural gas and

propane models are furnished with gas valves which have a built in gas pressure regulator. If necessary,

adjust to the proper value by removing cap and turning adjusting screw clockwise to increase manifold

pressure or counterclockwise to decrease manifold pressure.

Model Natural Gas Propane

MG

3.5” W.C. 11.0” W.C.

SG

3.5” W.C. 10.0” W.C.

Loading...

Loading...