5

PERFORMANCE

Your winch is a very powerful

machine. Treat it with respect, use it

with caution and always follow these

safety guidelines.

The responsibility

for safeinstalla-

tion and operation of the winch and

prevention of personal injury and

property damage ultimately rests

with you, the operator. There is

no substitute for the use of good

judgement and caution in operating

a winch.

The wire rope

may break before

the winch stalls. For heavy loads, use

a pulley block to reduce the load on

the wire rope.

1. Do not maintain power to the

winch if the motor stalls. Overloads

can damage the winch and/or the

wire rope and create unsafe oper-

ating conditions. FOR LOADS OVER

2/3 RATED CAPACITY, WE

RECOMMEND THE USE OF A

PULLEY BLOCK TO DOUBLE LINE

THE WIRE ROPE (Figure 1). This

reduces the load on the winch and

the strain on the wire rope by

approximately 50%. If attaching

back to vehicle, attach to the frame

or other load bearing part.

The

vehicle engine should be run-

ning during winch operation to

minimize battery drain and

maximize winch power and

speed.

If considerable winching is

performed with the engine off, the

battery may be too weak to restart

the engine.

2. AFTER READING AND

UNDERSTANDING THIS

MANUAL, LEARN TO USE

YOUR WINCH. After installing the

winch, practice using it so you will

be familiar with it when the need

arises.

3.

DO NOT “move” your vehicle to

assist the winch in pulling a load.

The combination of the winch and

vehicle pulling together could

overload the wire rope and the

winch itself.

4. KEEP WINCHING AREA CLEAR. Do

not allow people to remain in the

area during winching operations.

ALWAYS STAND CLEAR OF WIRE

ROPE/HOOK AND WINCH. IN THE

UNLIKELY EVENT OF ANY COMPO-

NENT FAILURE IT‘S BEST TO BE OUT

OF HARM‘S WAY.

5. INSPECT WIRE ROPE AND EQUIP-

MENT FREQUENTLY.

A FRAYED

WIRE ROPE WITH BROKEN

STRANDS SHOULD BE REPLACED

IMMEDIATELY.

Always replace

wire rope with the manufacturer‘s

identical replacement part (see

Replacement Parts List). Periodically

check the winch installation to

ensure that all bolts are tight.

6. USE HEAVY LEATHER GLOVES when

handling wire rope. DO NOT LET

WIRE ROPE SLIDE THROUGH YOUR

HANDS EVEN WHEN WEARING

GLOVES.

GENERAL SAFETY

INFORMATION

1 6,000 2722

2 5,465 2477

3 5,000 2268

4 4,670 2118

INTERMITTENT DUTY

SPECIFICATIONS

4

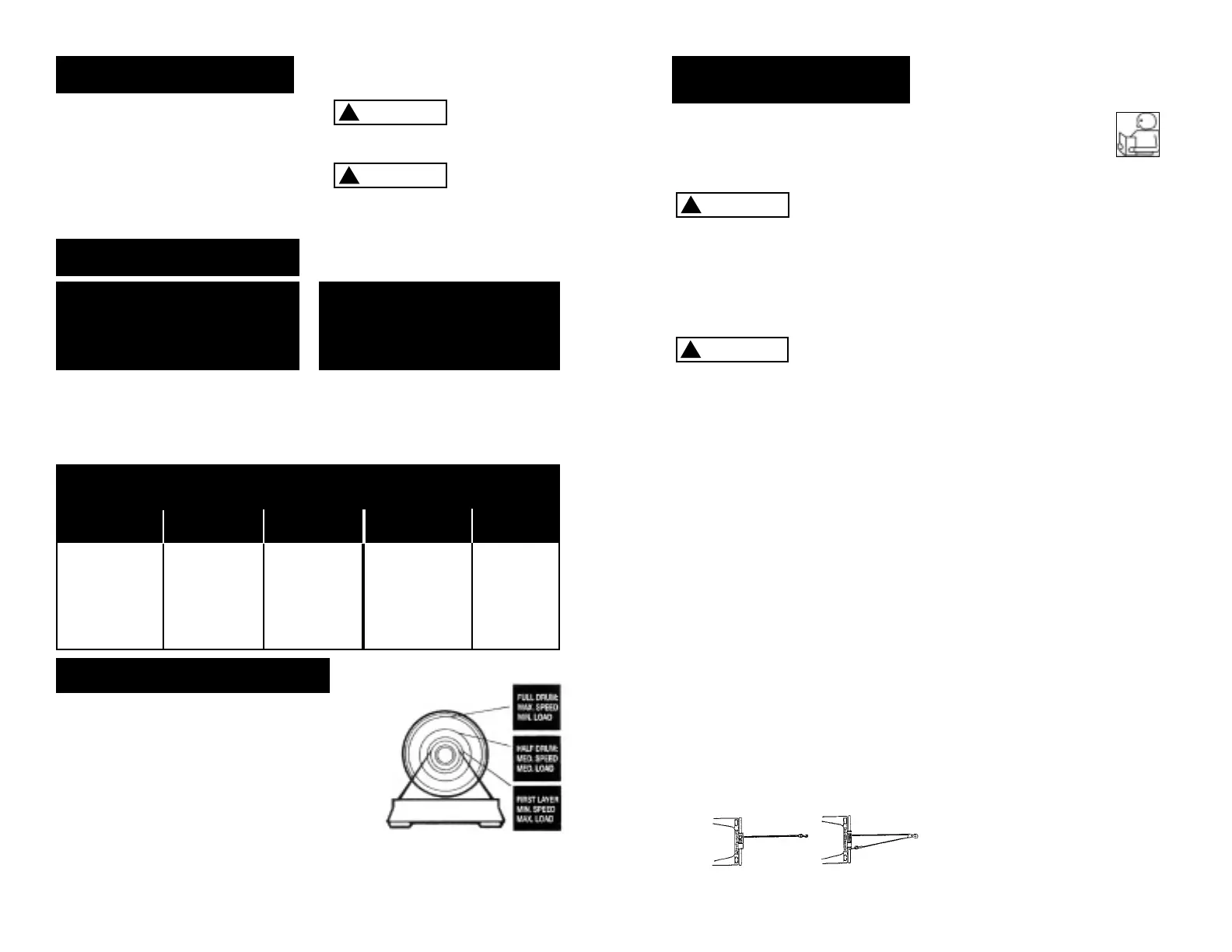

Figure 1

Single Line

Double Line

0 0 48 14.6 60 24 44.0 13.4 55 30

2,000 907 23 7.0 170 102 15.0 4.6 110 65

4,000 1814 13 4.0 320 210 11.0 3.4 200 100

6,000 2722 10 3.1 400 264 9.0 2.7 230 130

8,000 3629 NA NA NA NA 7.5 2.3 260 170

9,000 4082 NA NA NA NA 6.4 2.0 350 210

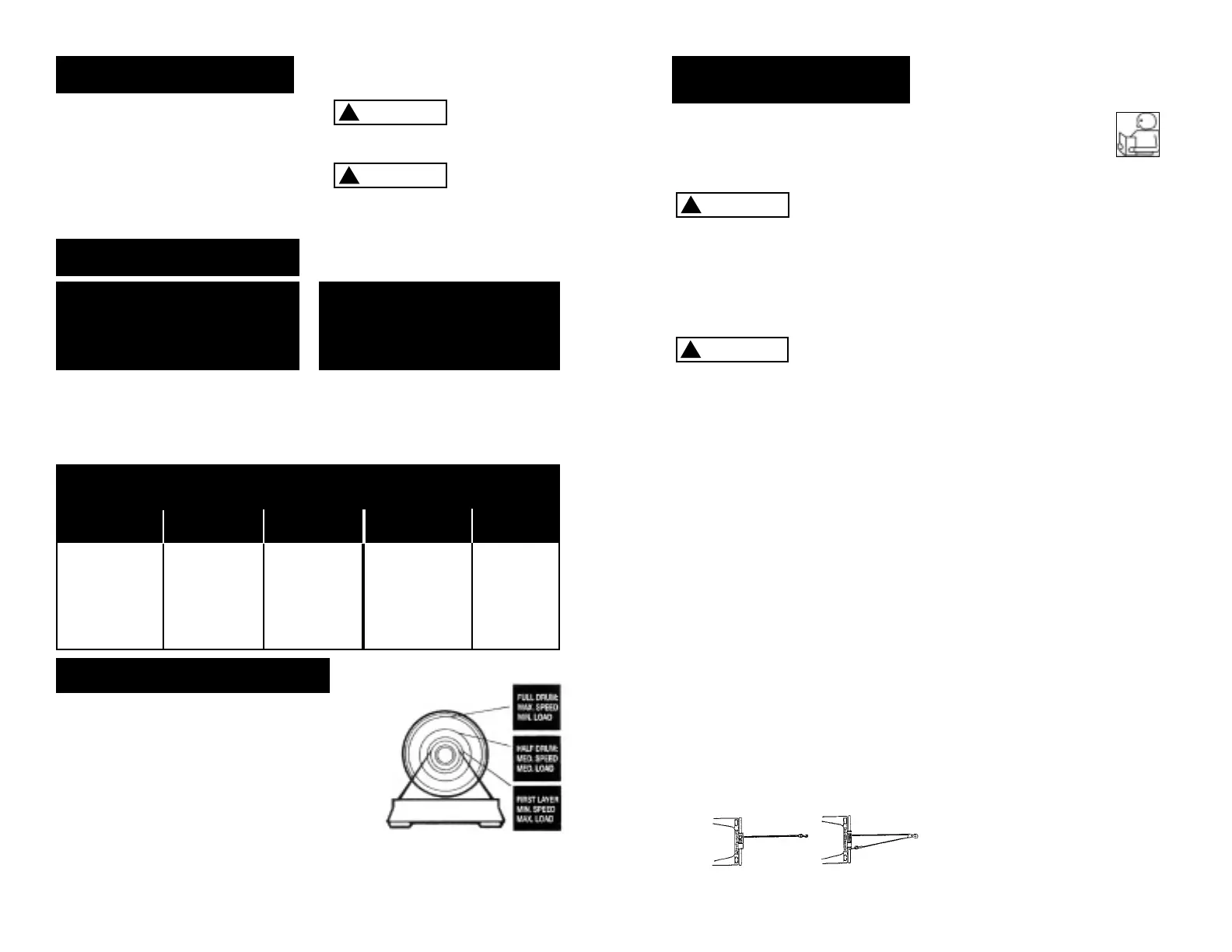

An electric winch is like any othe motor

driven power tool such as an electric drill

or saw. The electric motor should not be

allowed to become excessively hot.

Normal,precautions will extend the life

of your motor. Keep the duration of pulls

as short as possible. If the end of the

motor becomes uncomfortably hot

to touch, stop winching and allow the

motor to cool down.

If the winch

motor stalls,

do not continue to apply power

to the winch.

Brake housing

will get hot

during extended power out operation.

EP/EPi 6.0

Wire Rope Max. Pulling Capacity

Layer

lbs. kg

1 9,000 4082

2 8,190 3715

3 7,500 3402

4 7,010 3180

5 6,570 2980

EP/EPi 9.0

Wire Rope Max. Pulling Capacity

Layer

lbs. kg

Line Speed and Amp Draw

EP/EPi 6.0 EP/EPi 9.0

Load Line Speed* AMP Draw Line Speed* Amp Draw

Lbs. kg FPM MPM 12V 24V FPM MPM 12V 24V

EP/EPi 6.0 EP/EPi 9.0

Working Load* 6000 lbs. (2722 kg) 9000 lbs. (4082 kg)

Wire Rope

EP 6.0/9.0 100' x 21/64" (8.3mm x 30m)

EPi 6.0/9.0 125' x 21/64" (8.3mm x 37.5m)

Motor Type Series Wound Series Wound

Motor Output 12V 3.6 HP (2.7 kW) 4.6 HP (3.4 kW)

Motor Output 24V 2.0 HP (1.5 kW) 2.6 HP (1.9 kW)

Clutch Sliding Ring Gear Sliding Ring Gear

Brake Auto. Load-holding Auto. Load-holding

Gear Ratio 156:1 156:1

* Based on first layer performance

Loading...

Loading...