OWNERS MANUAL

14

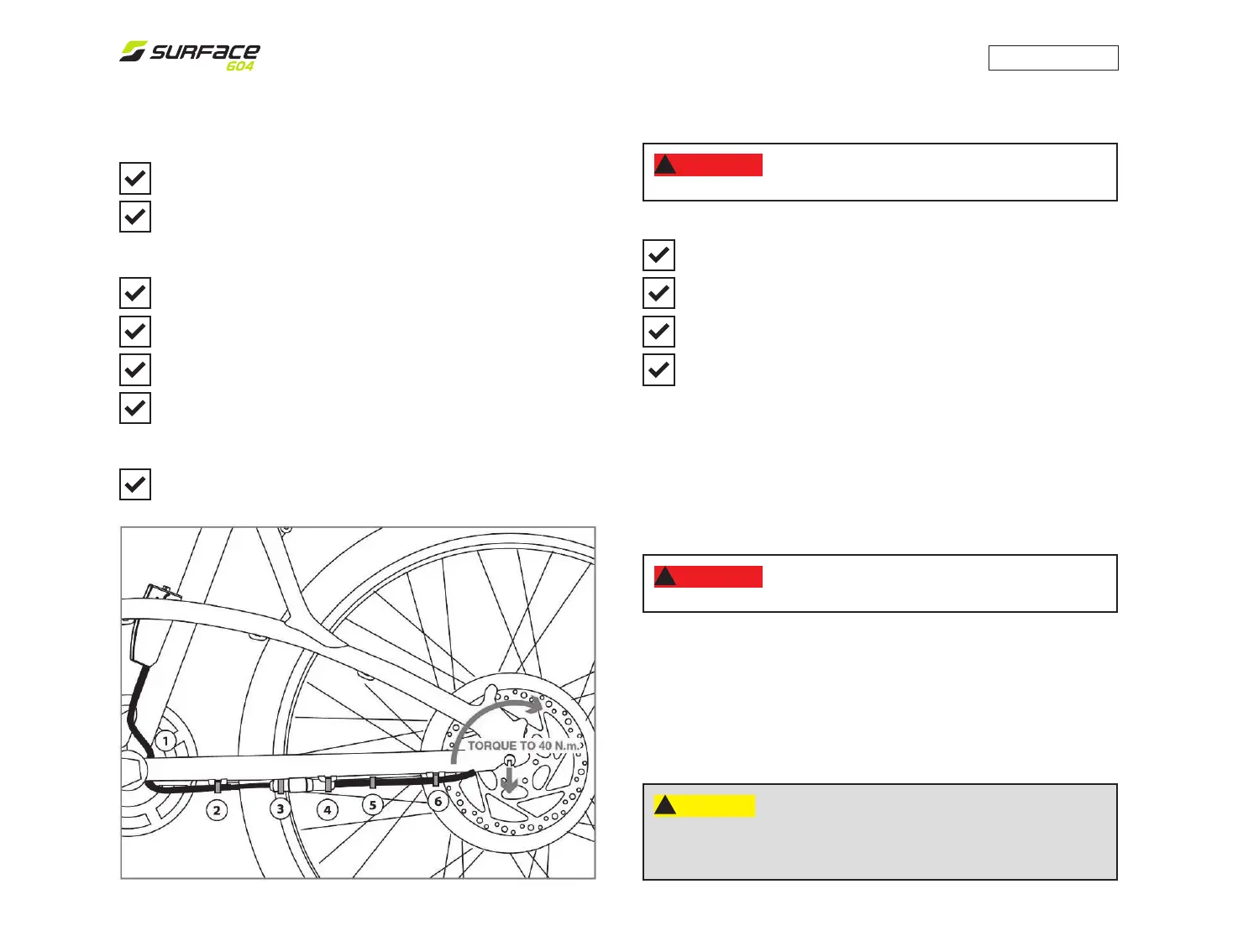

REMOVING AND INSTALLING BOLT-ON REAR WHEEL

TO INSTALL - Shift the rear derailleur to its outermost position

and pull the derailleur back with your right hand.

Put the chain on the smallest sprocket. Then, insert the wheel

into the frame dropouts and pull it all the way in to the dropouts.

The axle nut washers should be on the outside, between the

frame and the axle nut.

Make sure that the axle groove is pointing directly toward the

oor (6 o’clock).

Using the correct size wrench (15mm), tighten the axle nuts as

tightly as you can. Torque to 40 N.m. (30 ft/lbs)

Push the rear derailleur back into position.

Re-engage the brake quick release mechanism to restore correct

brake pad to disc clearance; spin the wheel to make sure it is cen-

ter in the frame and clears the brake pads; then squeeze the brake

lever and make sure that the brakes are operating correctly.

Reconnect the electric motor cables and fasten with zap- straps

in the required locations.

REMOVING AND INSTALLING BOLT-ON REAR WHEEL

TO REMOVE - Disconnect the electric motor cables and zap-

straps (located on the bottom left hand chain stay).

Shift the rear derailleur to high gear (the smallest rear sprocket)

and pull the derailleur body back with your right hand.

Using the correct size wrench, loosen the two axle nuts.

Lift the rear wheel o the ground a few inches and, with the

derailleur still pulled back, push the wheel forward and down

until it comes out of the rear dropouts.

WARNING:

!

The motor acts as a rear hub and should not

be adjusted once the rear wheel is properly mounted.

WARNING:

!

Riding with an improperly tightened seat post can

allow the seat to turn or move and cause you to lose control and fall.

SEATPOST QUICK RELEASE

The seat post quick release clamp works exactly like the front wheel

quick release. While a quick release looks like a long bolt with a lever

on one end and a nut on the other, the quick release uses a cam action

to rmly clamp the seat post.

The quick release cam squeezes the seat collar around the seat post to

hold the seat post securely in place. The tension- adjusting nut controls

the amount of clamping force. Turning the tension-adjusting nut clockwise

while keeping the cam lever from rotating increases the clamping force;

turning it counterclockwise while keeping the cam lever from rotating re-

duces clamping force. Less than half a turn of the tension-adjusting nut

can make the dierence between safe and unsafe clamping force.

CAUTION:

!

Your Surface604 bicycle is equipped with

disc brakes. Be very careful not to damage the disc, caliper or brake

pads when re-inserting the disc into the caliper. Never activate a disc

brakes control lever unless the disc is correctly inserted in the caliper.

Loading...

Loading...