5 Running without Needle

4) Check vibration from machine.

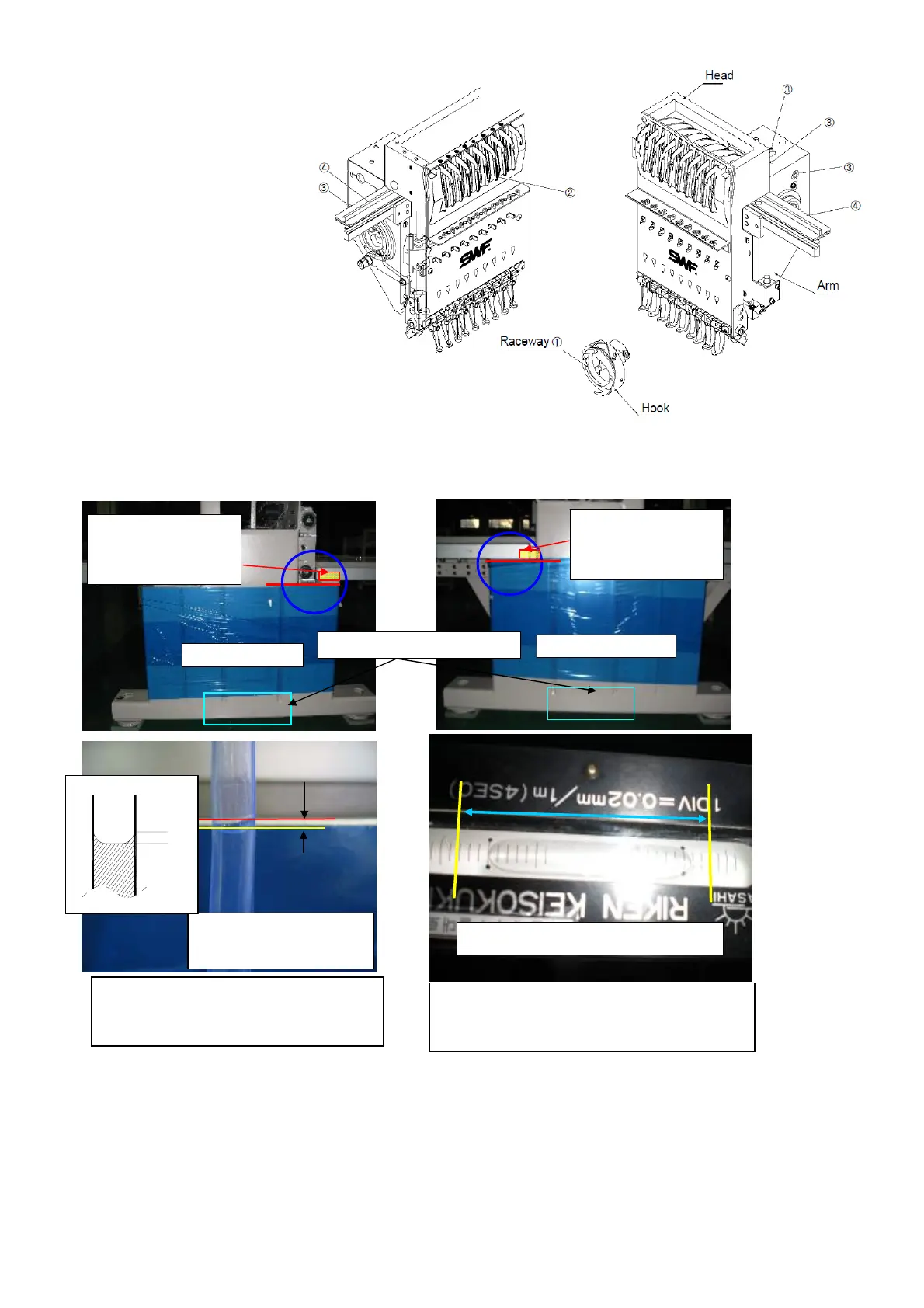

6 How to check level status and instal Table Support

(1) Leveling L/R :With water Hose, adjust less than error scope 0.5mm .

(2) Leveling F/R :Use error scope 2/100 level (by the central, left and right, within three grid )

2) With normal sewing wroking

test design,run the machine at

600 RPM

3) Check Point: Bearing Bushing

seperation, Shaft heat, noise

from frame/each belt part.

5) After finishing Running Test,

check status of machine.

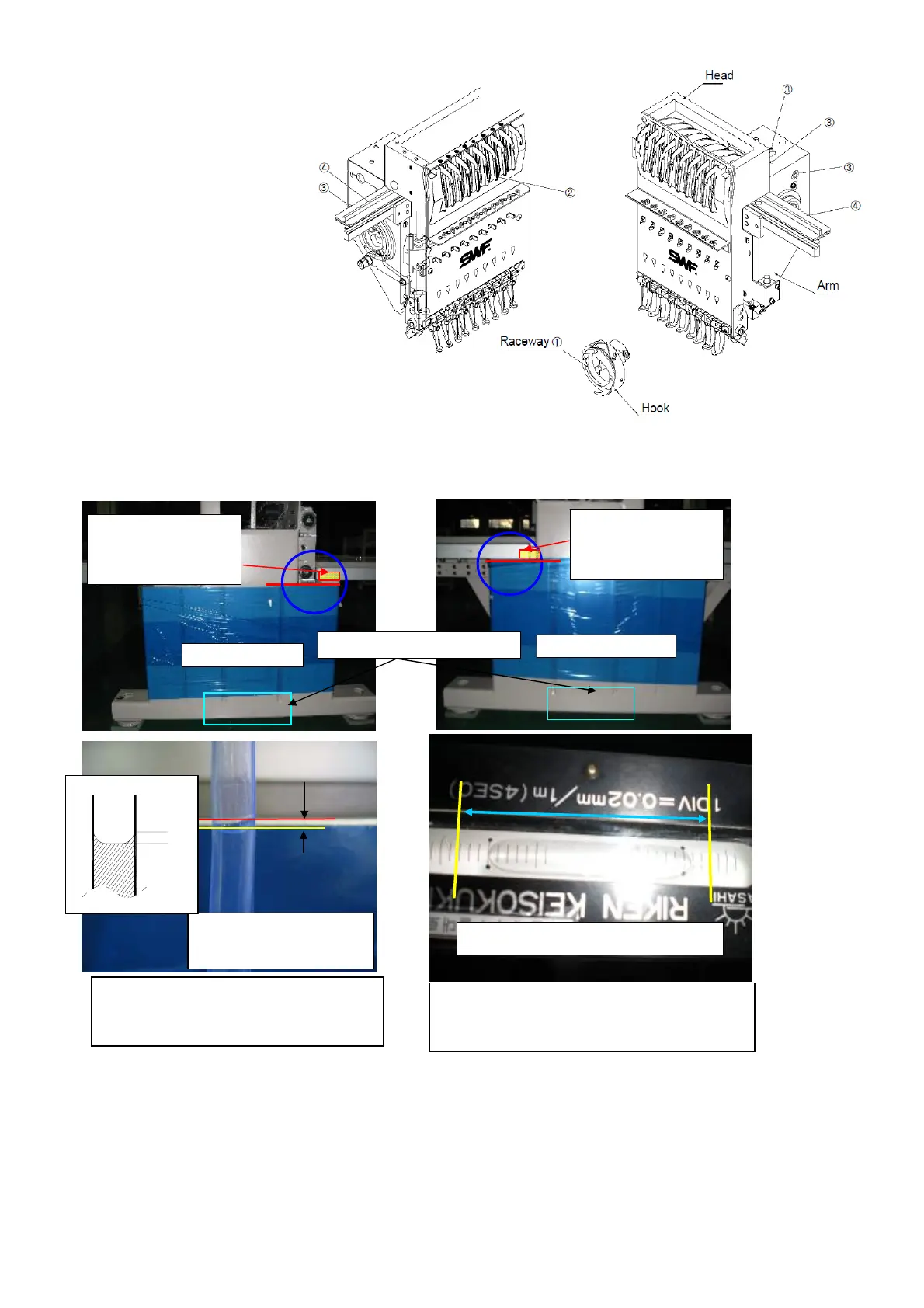

1) Oiling the essential part

Arm,Head,Rotary Hook,(Pic

1~4)

Levelitlessthan0.5mmerror

scopeforequalingtheheightof

0markandBod

side

Whenleveling(F/R),withintolerances.

Whenlevelingthewater,Hex.Boltwillgetalotof

loads,so,putuptheBeamBodywithliftingtoolsfor

adjustingtheheightandthenputdownthe

InstallitbottomoftheLevelingBaseandBody

within10MM,ifthedifferenceisbig,

Addtheironplateforadjusting.

(Attach the picture of this in the report

Beam Body

Beam Body side(right)

Adjusting the height with lifting

Asindicatedbynoted,

Levelingitwitha

waterlevelL/R,F/R.

Asindicatedbynoted,

Levelingitwitha

waterlevelL/R,F/R.

X

O

Page 11 Of 17 (주)SUNSTAR SWF CS Center

Loading...

Loading...