MAINTENANCE

211

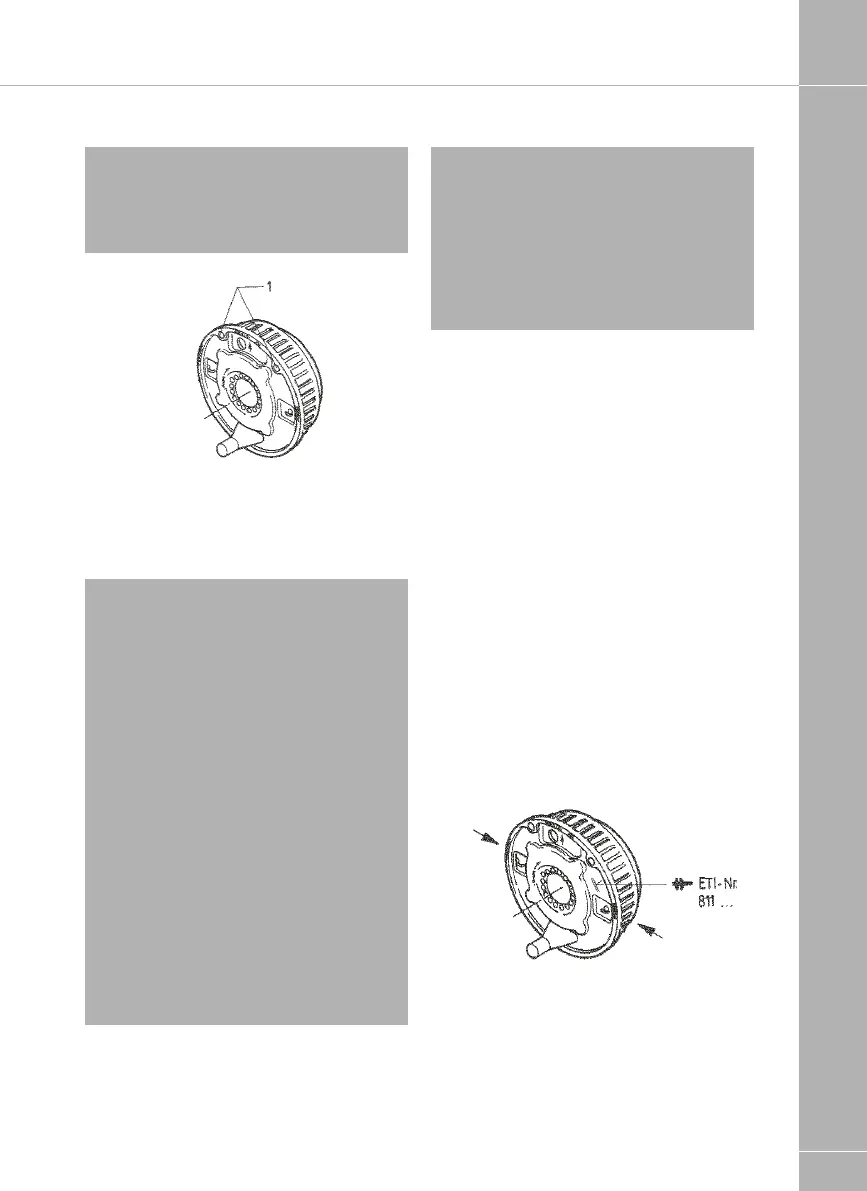

Note: The hub bearing is not protected

against water ingress. Check wheel brake

linings for wear every 10,000 kilometers

(6200 miles) or every 12 months via the

inspection hole

Fig. 5

(Fig. 5/Item 1). Adjust if necessary. Where

continuous travel in hilly regions or high

mileage is experienced, earlier inspection and

adjustment may be necessary.

Note: The flanged hub-nut, located under

the dust cap, used to keep the brake drum

in situ, is a ONE-SHOT NUT (ie. must

only be used once). If removed it must be

replaced with a NEW flanged nut - torqued

to 290 ± 10 Nm (214 +/- 1 7.5 lbs/ft). A

small amount of special mineral grease,

available from AL-KO must be applied to

stub axle thread prior to fitting the new

flanged nut. After fitting excess grease must

be removed with white spirit.

The rear hexagon cap head bolt located

under the black plastic cap MUST NOT BE

DISTURBED under any circumstance. Inter-

ference with this nut will result in immediate

tyre wear and damage to the braking sys-

tem and WILL INVALIDATE ALL WARRAN-

TIES. Should the rear nut accidentally be

disturbed then the complete axle must be

returned to AL-KO for resetting of the toe-in

and camber.

No attempt should be made to remove

the bearing. In the event of damage to the

bearing or drum, only the drum complete

with bearing and circlip will be available as

a spare. No grease is used in the hub other

than the mineral grease on the stub axle.

No grease should be placed in the DUST

cap. This is not a grease cap as used in all

previous hubs

Spare parts

Spare parts are safety critical parts! For

this reason when fitting spare parts we

recommend the use of original AL-KO

parts or those parts that they have explicitly

approved. The reliability, safety and suitability

of parts designed especially for their products,

has been determined using a special test

procedure. In spite of constantly monitoring

the market they are unable to assess or vouch

for other products.

If repair work or servicing is required, AL-KO

have a large network of AL-KO service stations

throughout Europe.

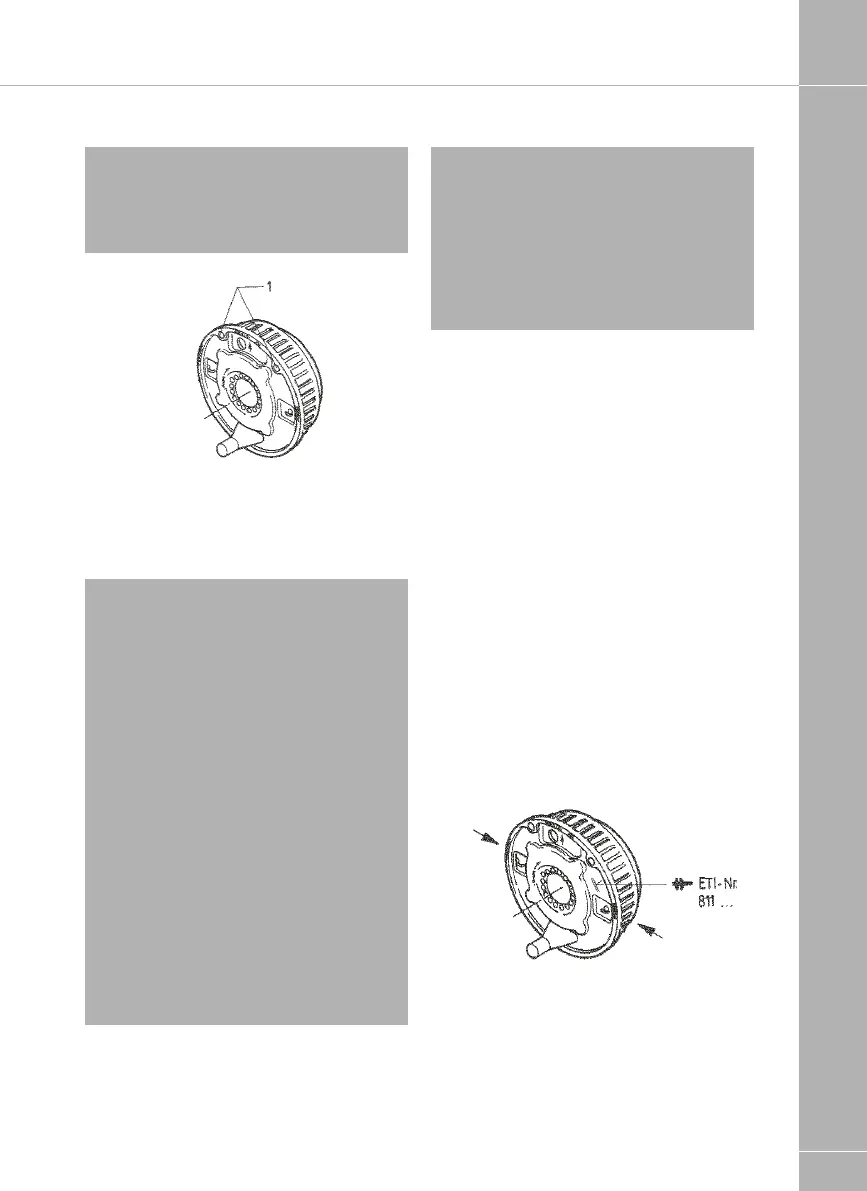

To establish the correct spare parts required

for your axle you should always quote the axle

type (axle identification plate Fig. 1, page 209)

and Spare Part Identification no. (ETI No.),

which will be stamped onto the wheel brake

or on the identification plate (Fig. 6). Please

establish these numbers before contacting

AL-KO or a Service Agent.

Fig. 6

The AL-KO rubber suspension axle has been

designed and developed to suit all types of

road conditions and is maintenance free.

Three rubber elements are contained within

an hexagonal axle tube. These provide

suspension and have inherent damping

characteristics.

Loading...

Loading...