STEALTH DIGI-CUT100

4 PRODUCT DESCRIPTION

4.1 The voltage of the output ends is very high. Don’t touch with the output ends, cutting

torch and other conductive parts while setting up an electric circuit.

4.2 For the safety of the equipment and the persons, the customer must correctly make

grounding or protection according to the power supply system:using 4 mm2 lead to

connect the protection grounding of the cutting machine.

4.3 Cutting operating should be carried out in dry and good ventilating area. The

surrounding objects should be not less than 0.5m away from the cutting machine.

4.4 Before cutting , the operator should read the operation instructions carefully and use

the machine correctly.

5 PANEL FUNCTION DIAGRAMS

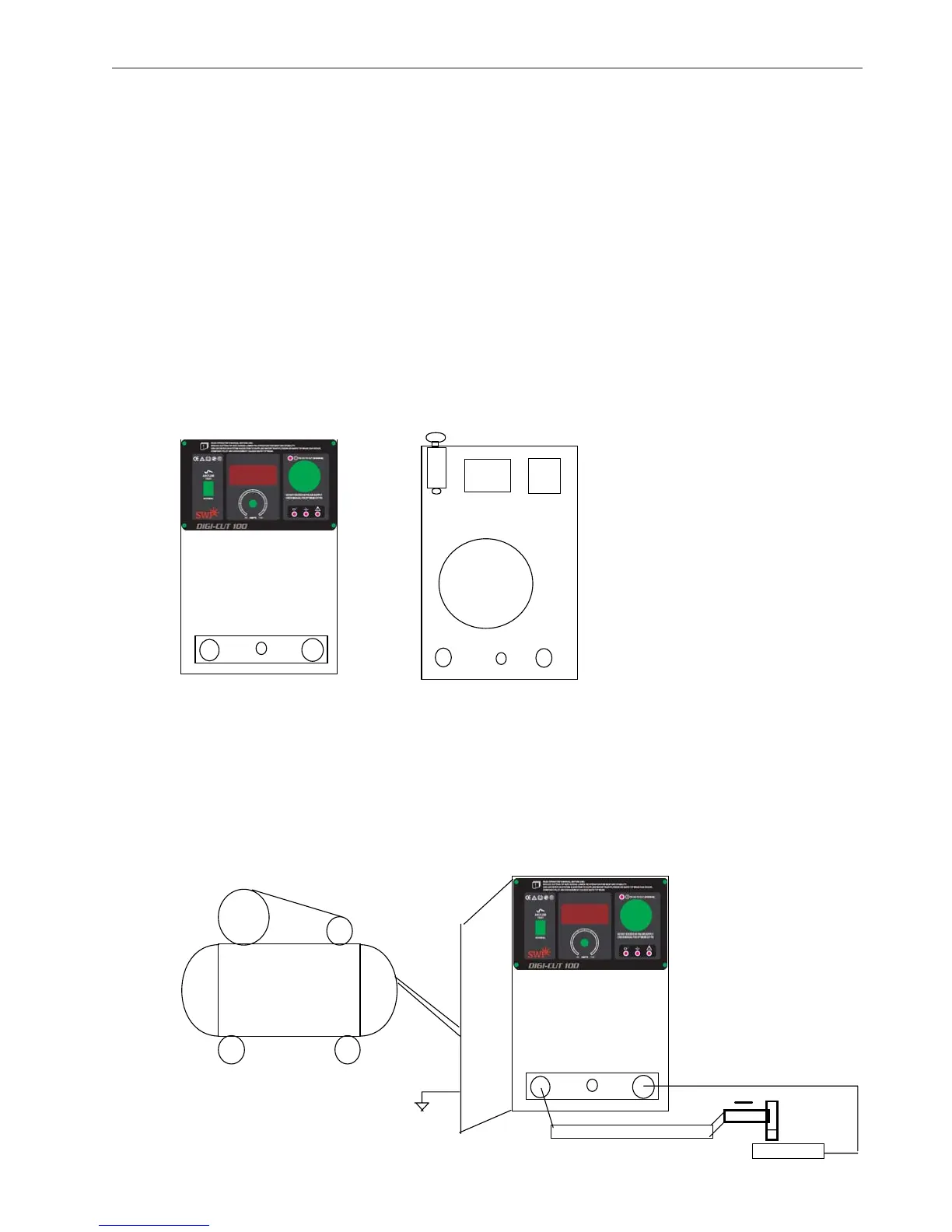

FRONT PANEL

BACK PANEL

torch and other conductive parts while setting up an electric circuit.

2. For the safety of the equipment and the persons, the customer must correctly make

grounding or protection according to the power supply system:using 4 mm

2

lead to

connect the protection grounding of the cutting machine.

3. Cutting operating should be carried out in dry and good ventilating area. The surrounding

objects should be not less than 0.5m away from the cutting machine.

4 . Before cutting , the operator should read the operation instructions carefully and use the

machine correctly.

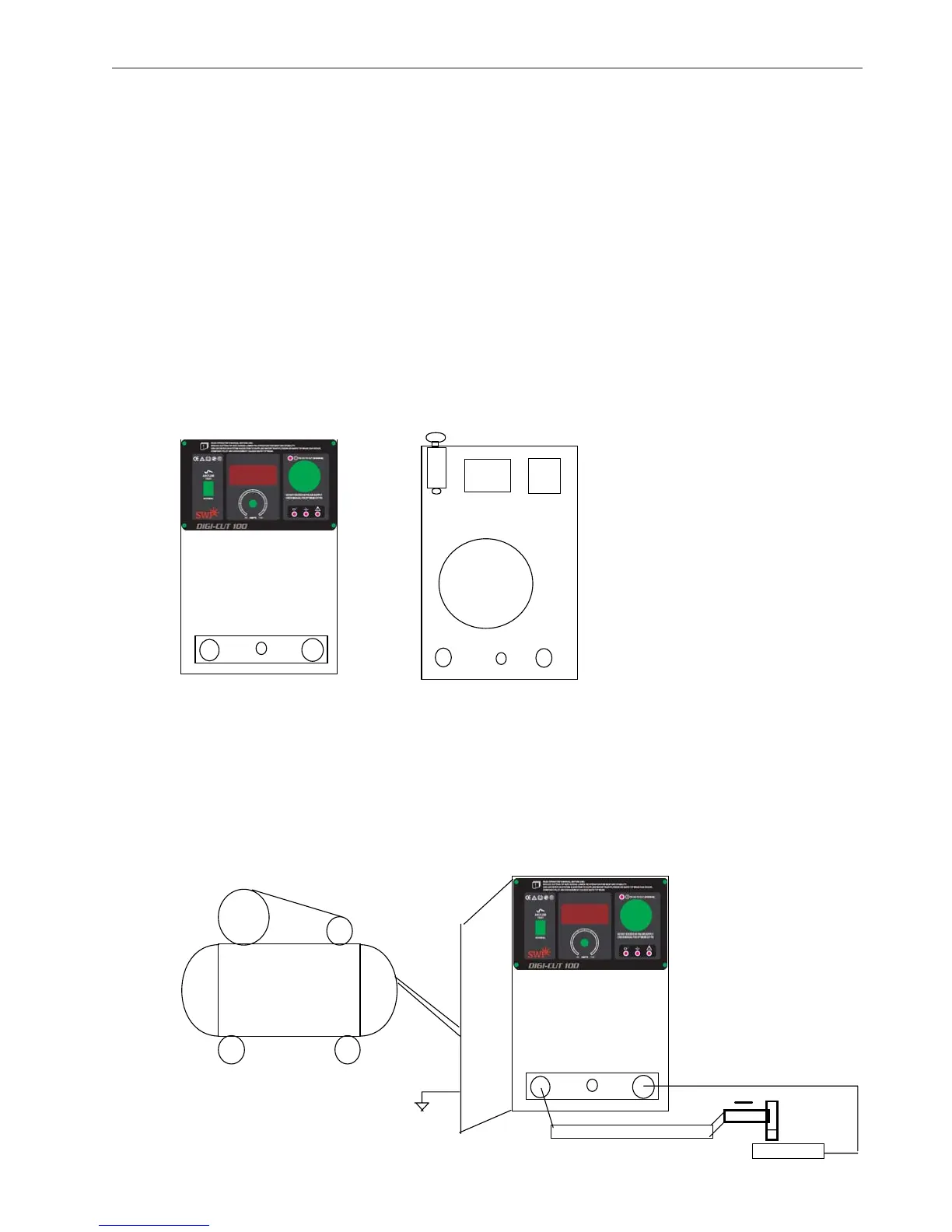

5. THE SKETCH OF FUNCTION AND CONNECT ING

1.

indication of cutting current 2.power indication 3. warning indication 4. cutting/testing gas switch

5. cutting current regulator 6. cutting torch cable 8. workpiece cable 9. nameplate

10. air pressure-reduced valve 11. pressure air entrance 12. fan

13. indication of air pressure-reduced valve 14. grounding column 15. input cable 16,power switch

()

17.indication of lower air 18. indication of PSI OK TO CUT minimum 19.fuse 20A

BACK PANEL

FRONT PANEL

11

12

9

14

15

16

6

19

8

torch and other conductive parts while setting up an electric circuit.

2. For the safety of the equipment and the persons, the customer must correctly make

grounding or protection according to the power supply system:using 4 mm

2

lead to

connect the protection grounding of the cutting machine.

3. Cutting operating should be carried out in dry and good ventilating area. The surrounding

objects should be not less than 0.5m away from the cutting machine.

4 . Before cutting , the operator should read the operation instructions carefully and use the

machine correctly.

5. THE SKETCH OF FUNCTION AND CONNECT ING

1.

indication of cutting current 2.power indication 3. warning indication 4. cutting/testing gas switch

5. cutting current regulator 6. cutting torch cable 8. workpiece cable 9. nameplate

10. air pressure-reduced valve 11. pressure air entrance 12. fan

13. indication of air pressure-reduced valve 14. grounding column 15. input cable 16,power switch

()

17.indication of lower air 18. indication of PSI OK TO CUT minimum 19.fuse 20A

BACK PANEL

FRONT PANEL

1. Cutting current indicator

2. Power ON/OFF

3. Warning light

4. Cutting/testing gas switch

5. Cutting current indicator

6. Cutting torch cable

8. Workpiece cable

9. Nameplate

10. Air pressure-reducing valve

11. Air IN pressure

12. Fan

13. Air pressure-reducing valve

indicator

14. Grounding column

15. Input cable

16. Power switch

17. Low air pressure indicator

18. PSI OK TO CUT (minimum)

indicator

19. Fuse 20A

Loading...

Loading...