button. The following test parameters are

shown on the screen: test mode, test duration,

test cycles (completed or remaining), turntable

speed, and vacuum suction level (%).

60 / 72 RPM Turntable Rotation Speed*

Models 5135 and 5155 offer both 60 rpm and 72

rpm turntable rotation speed. This enables the

operator to select the speed referenced in the

test standard.

NOTE: The turntable speed on previous versions of

the Taber Abraser was dependent on the electrical

line frequency. At 60Hz, the turntable speed was 72

rpm and at 50Hz the turntable speed was 60 rpm.

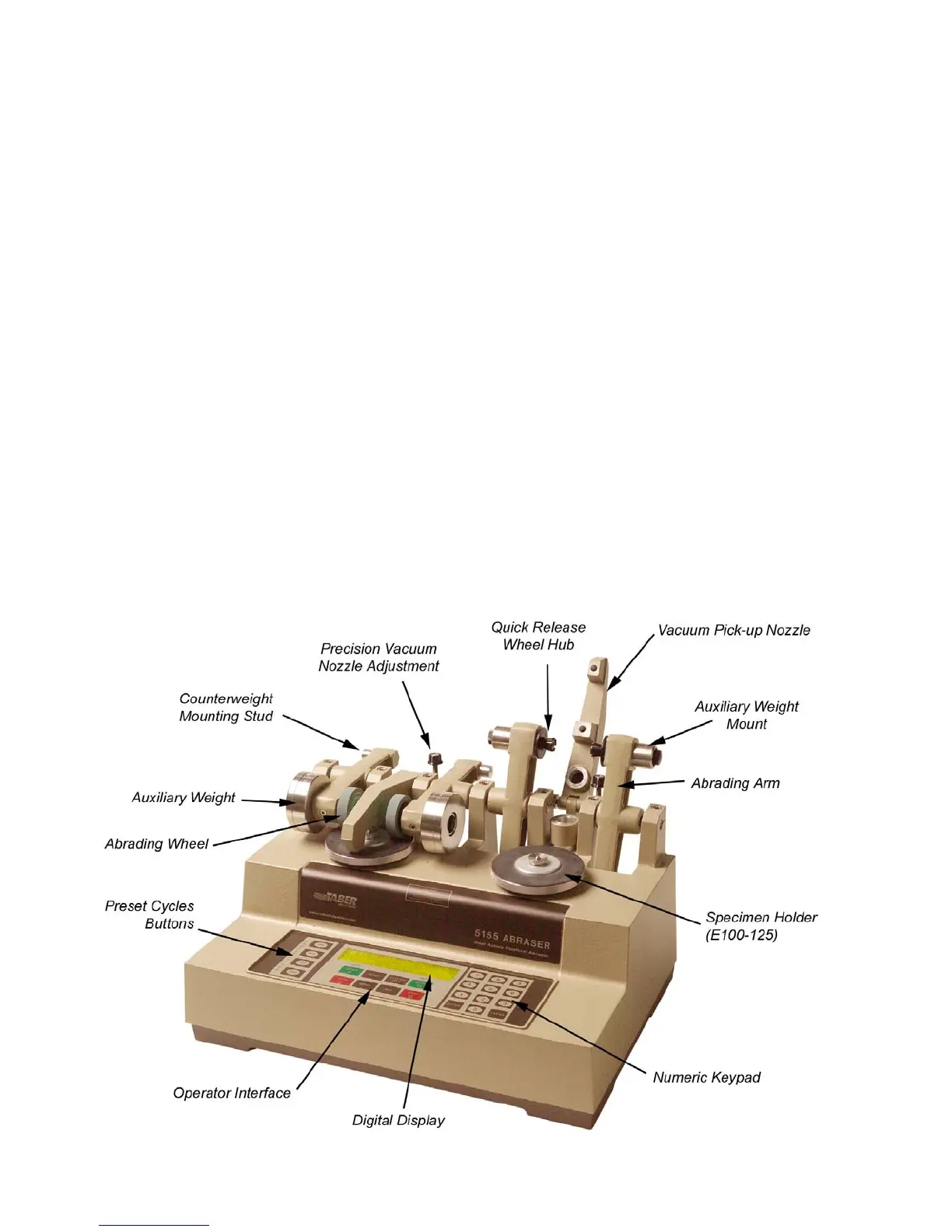

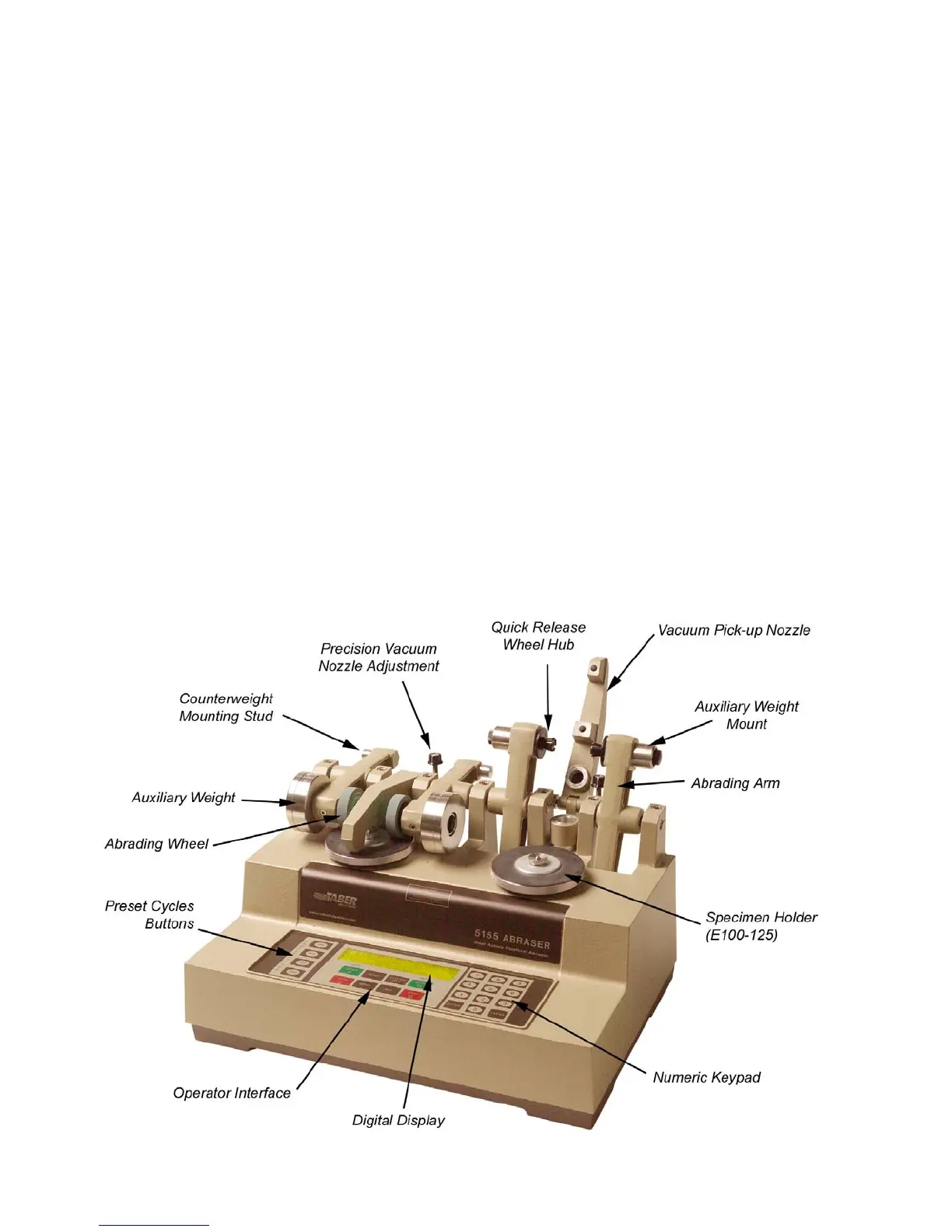

Preset Cycles Buttons*

The operator interface includes four commonly

used preset cycles buttons. This enables the

operator to automatically program 100, 500,

1000 or 2500 test cycles. The buttons may also

be used to “add to” the cycle count by the

corresponding incremental values.

Abrading Head Assemblies

Models 5135 and 5155 have independent

abrading arms of forged aluminum alloy that

pivot on ball bearings. The forward end of the

arm has a quick release wheel-mounting hub to

which the abrading wheel is mounted. The arms

are precision balanced to ensure exacting

results. Each arm applies 250 grams force

against the specimen with the wheel mounting

assembly in place (exclusive of the mass of the

wheels itself).

The outer end of the abrading head assembly

allows the auxiliary weight to be mounted

concentric with the abrading wheel. A stud on

the rear end of the abrading arm may be used to

carry a counterweight when it is desired to

reduce the wheel load to less than 250 grams

when testing delicate materials. It may also be

used to hold an abrading wheel as a

counterweight to compensate for the mass of

the working wheel.

Quick Release Mounting Hub*

An expanding collet hub design with push-button

operation permits quick wheel mounting, without

the need of a locking nut. A spring loaded,

beveled retaining nut provides a positive locking

force on the hub retaining lip making certain the

wheels remain securely fastened until

disengaged. The increased clearance results in

a larger viewing area of the test specimen.

4 5135 / 5155 Operating Instructions ver 1.1

Loading...

Loading...