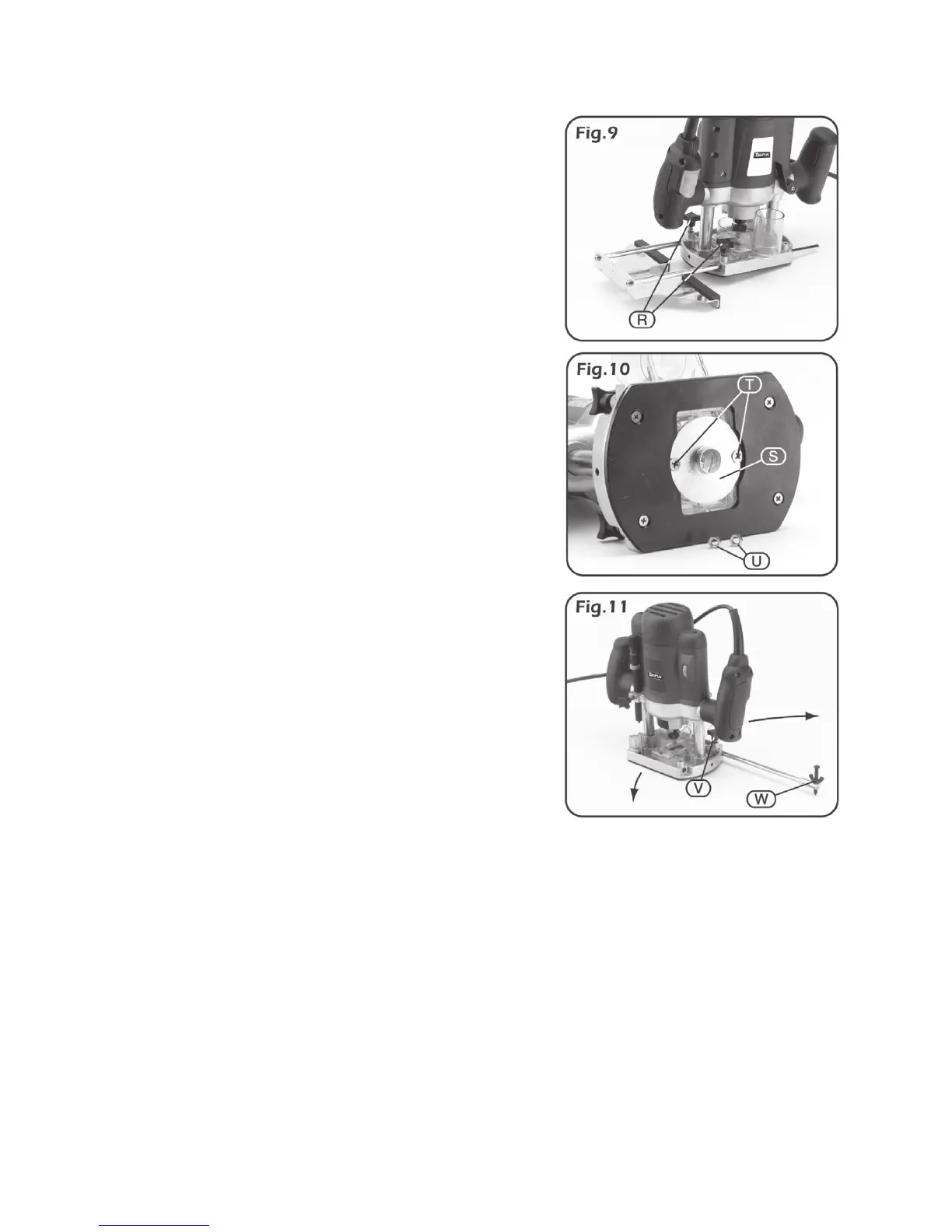

PARALLEL

GUIDE

ROUTING

(Fig.9)

Ensure the edge along which the guide is going to travel is

smooth and true as any inconsistencies will translate into

the cut.

Pass the parallel guide rods through the four pointes in the

router’s base and secure in place with lock knobs ®. When

using the parallel guide an even pressure should be applied

to each face except on a leading/trailing edge of a work

piece. When leading on to a work piece apply the pressure

to the forward face until both faces are on. When trailing off

a work piece apply the pressure to the rear face until the cut

is complete.

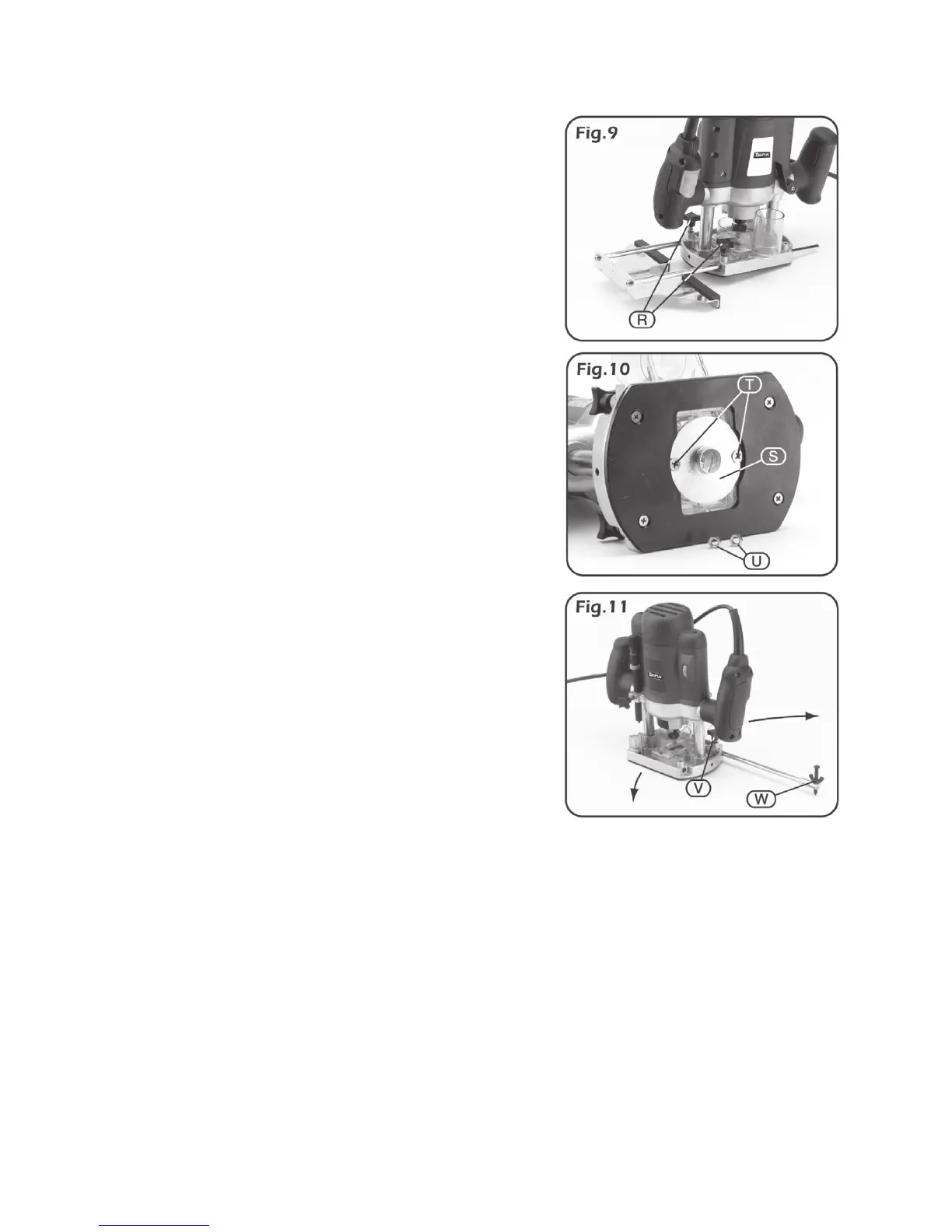

16mm

INNER-18mm

OUTER

DIAMETER

TEMPLATE

FOLLOWER

(Fig.

10)

For detailed information on templates refer to a routing/

woodworking book.

Lay the template follower (S) into the recess. Ensure the

template follower faces downward and secure with the two

countersunk screws (T)

NOTE:

For operations using the template follower without

the dust extraction port tted use the two 8mm nuts (U).

PIVOT

ROD

TRAMMEL

(Fig.11)

Secure one of the parallel guide rods into the rear channel.

Remove the rod locking knob from the front channel and

secure it into the additional rod locking point. Loosen the

wing nut and slide the trammel (W) on to the rod end. Adjust

the point height to suit before locking the wing nut. Adjust

the distance between the router bit and pivot point.

Loading...

Loading...