TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

22-1022-10

(14-16 N(14-16 N⋅⋅m).m).

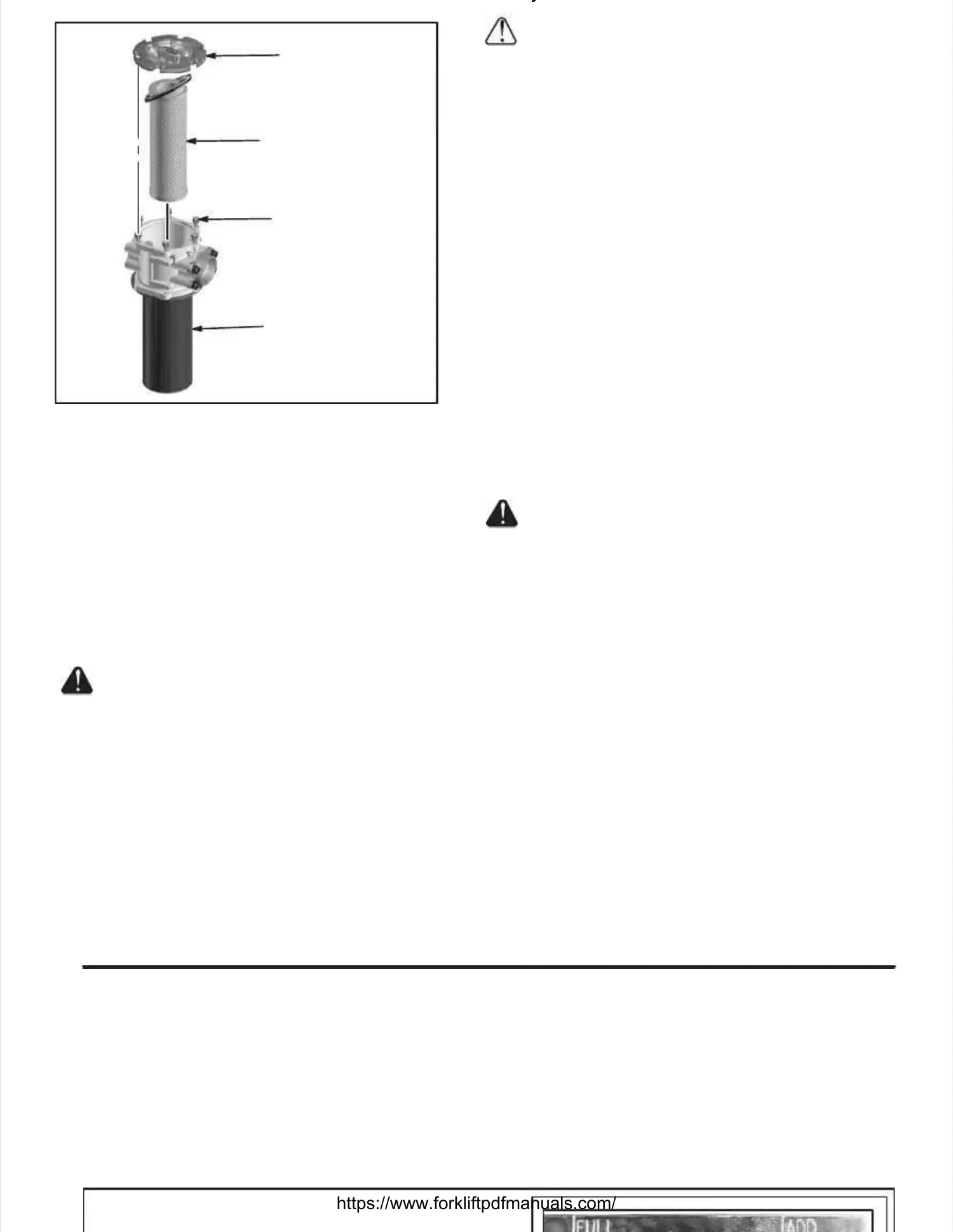

FILTERFILTER

HEAD / BOWLHEAD / BOWL

ASSEMBLASSEMBLYY

BOLTBOLT

RETURNRETURN

FILTERFILTER

COVERCOVER

Illustration 22-15. Illustration 22-15. Hydraulic Hydraulic Return Return FilterFilter

Changing The Hydraulic FluidChanging The Hydraulic Fluid (Illustration(Illustration

22-16)22-16).. The hydraulic The hydraulic fluid should fluid should be changedbe changed

periodically (refer to theperiodically (refer to the Preventive MaintenancePreventive Maintenance

chart in thechart in the AppendicesAppendicesfor hydraulic fluid changefor hydraulic fluid change

interval). interval). The hydraulic The hydraulic fluid must fluid must also bealso be

changed in the event of a catastrophic failure of achanged in the event of a catastrophic failure of a

hydraulic hydraulic component. component. Refer Refer to theto the Fuel andFuel and

Lubricant SpecificationsLubricant Specificationschart in thechart in the Appen-Appen-

dicesdicesfor the proper type of fluid to be used andfor the proper type of fluid to be used and

perform the following procedures to change theperform the following procedures to change the

hydraulic fluid:hydraulic fluid:

Death or serious injury couldDeath or serious injury could

result from result from a runaway truck. a runaway truck. Park the truck Park the truck onon

a hard, level surface, apply the parking brake,a hard, level surface, apply the parking brake,

block the wheels in both directions to preventblock the wheels in both directions to prevent

movement of the truck and Lock-Out & movement of the truck and Lock-Out & TTag Outag Out

yy

Plug all hoses when they arePlug all hoses when they are

disconnected to prevent foreign matter fromdisconnected to prevent foreign matter from

entering the hydraulic system.entering the hydraulic system.

1.1. Park tPark the trhe truck on a hauck on a hard, lerd, level svel surfurfaceace, blo, blockck

the wheels in both directions, apply the park-the wheels in both directions, apply the park-

ing brake and Lock Out & Tag Out the truck.ing brake and Lock Out & Tag Out the truck.

2.2. ProvidProvide a sue a suitablitable conte containerainer, re, remove move the the draindrain

plug and drain the hydraulic fluid.plug and drain the hydraulic fluid.

3.3. RemRemove tove the ache accescess cap fs cap from trom the hyhe hydradrauliulicc

tank.tank.

4.4. RemRemove ove the the brebreathather er filfilterter..

5.5. RemRemove tove the rehe returturn fin filtelter (rr (refeefer tor to HydraulicHydraulic

Return Filter ReplacementReturn Filter Replacementfor removal pro-for removal pro-

cedures).cedures).

6.6. RemRemove thove the sucte suction stion strairainerners from ts from the hydhe hydraurau--

lic tank and lic tank and clean in solvent. clean in solvent. Dry with comDry with com--

pressed air.pressed air.

7.7. AftAfter aler all the fl the fluiluid has bd has been dreen drainained fred from thom thee

tank, remove the access cover(s) andtank, remove the access cover(s) and

O-ring(s).O-ring(s).

8.8. Steam Steam clean clean the the interiinterior oor of thf the hyde hydraulic raulic tank.tank.

Do Not clean the interior ofDo Not clean the interior of

the hydraulic tank with a flammable solvent;the hydraulic tank with a flammable solvent;

this can create a serious fire hazard.this can create a serious fire hazard.

9.9. InsInstaltall nl new ew retreturn urn filfilterter..

10.10. Re-insRe-install suction straintall suction strainers.ers.

11.11. Re-install accesRe-install access cover(s) s cover(s) and O-ring(s).and O-ring(s).

Inspect O-ring(s) and replace if necessary.Inspect O-ring(s) and replace if necessary.

12.12. Re-insRe-install the draitall the drain plug.n plug.

13.13. Install new Install new breather filterbreather filter..

14.14. Slowly fill tank Slowly fill tank with hydraulic fluid with hydraulic fluid from the fillerfrom the filler

filter port (see Illustration 22-16) while inspect-filter port (see Illustration 22-16) while inspect-

ing for leaks (pay particular attention to theing for leaks (pay particular attention to the

access covers). access covers). If a leak If a leak is detected, is detected, repairrepair

before adding before adding additional hydraulic additional hydraulic fluid. fluid. IfIf

there are no leaks detected, fill the hydraulicthere are no leaks detected, fill the hydraulic

tank to the FULL mark on the fluid level dip-tank to the FULL mark on the fluid level dip-

stick (see Illustration 22-16).stick (see Illustration 22-16).

15.15. Inspect hydraulic Inspect hydraulic tank fittings tank fittings and hoses forand hoses for

leaks. leaks. Tighten Tighten connections / bolts connections / bolts as required.as required.

Hydraulic Hose Assemblies and Fittings.Hydraulic Hose Assemblies and Fittings. AllAll

hydraulic hose assemblies should be checkedhydraulic hose assemblies should be checked

daily for chafdaily for chaffing or fing or cracking. cracking. Check daily Check daily toto

ensure that there are no loose fittings on theensure that there are no loose fittings on the

hydraulic connections.hydraulic connections.

Loading...

Loading...