9-79-7TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

2.2. EnsEnsure ture that that the inhe inchiching vang valve ilve is not es not engangagedged

nor sticking.nor sticking.

Hydraulic Checks.Hydraulic Checks. Before checking the torqueBefore checking the torque

converter, transmission, and associated hydraulicconverter, transmission, and associated hydraulic

system for pressures and rate of flow, it is essen-system for pressures and rate of flow, it is essen-

tial that the following preliminary checks be made.tial that the following preliminary checks be made.

NOTE:NOTE: Do not attempt these checkDo not attempt these checks with cold oils with cold oil..

1.1. CheCheck ck the the oil oil levlevel iel in thn the tre transansmismissiosion. n. ThiThiss

should be done with the oil temperatureshould be done with the oil temperature

between +180between +180°°F and +200F and +200°°F (+82F (+82

F toF to

+93+93

F), and the engine operating at idle.F), and the engine operating at idle.

quarter throttle for 30 seconds, let off accelera-quarter throttle for 30 seconds, let off accelera-

tor for 10 seconds.tor for 10 seconds.

5.5. RepRepeat steat step 4. untep 4. until the deil the desirsired coned conververter outer out-t-

let temperature is reached.let temperature is reached.

Full throttle stall speeds for anFull throttle stall speeds for an

excessive length of time will overheat theexcessive length of time will overheat the

converter.converter.

6.6. WheWhen checn checkinking the prg the pressessureures, als, alwayways checs checkk

the charge pump and converter out pressuresthe charge pump and converter out pressures

first.first.

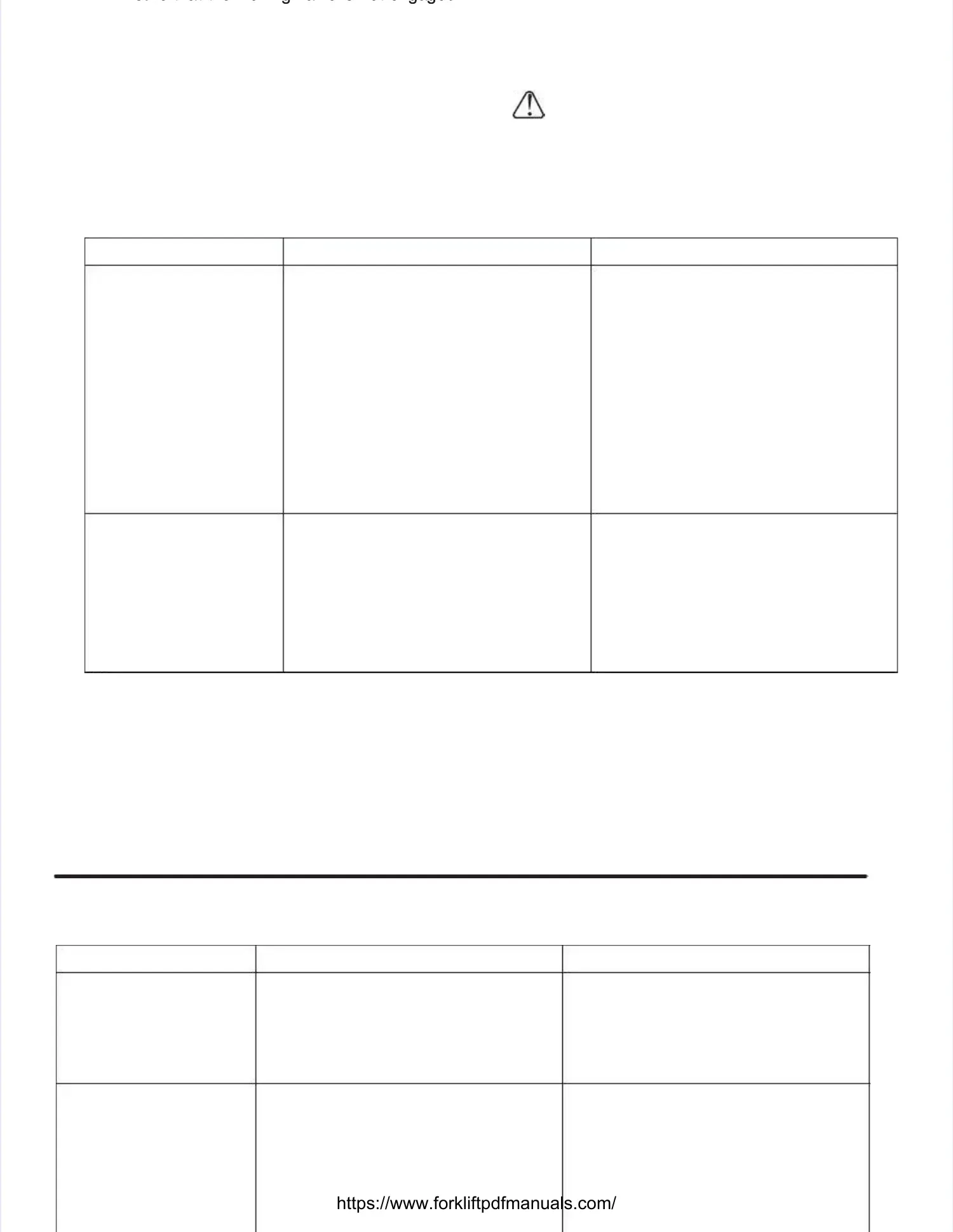

PPrroobblleemm CCaauussee CCoorrrreeccttiioonn

11.. LLow ow cclluuttcchh

pressurepressure

1.1. LoLow ow oil il lelevvelel..

2.2. CluClutch tch prepressussure rre reguegulatlating ing valvalveve

spool is stuck open.spool is stuck open.

3.3. DefDefectective ive chachargirging ng pumpump [p [240 240 --

300 psi (16.6 - 20.7 bar) normal300 psi (16.6 - 20.7 bar) normal

operating pressure].operating pressure].

4.4. BroBroken ken or or worworn cn clutlutch ch shashaft ft oror

piston sealing rings.piston sealing rings.

5.5. CluClutch tch pispiston ton blebleed ved valvalve ste stuckuck

open.open.

1.1. FiFill ll to to propropeper r lelevevel.l.

2.2. CleClean an valvalve ve spospool ol and and houhousinsing.g.

3.3. ReReplplacace ce chahargrgining pg pumump.p.

4.4. RepReplaclace see sealialing ng rinrings ogs or cr clutlutchch

shaft.shaft.

5.5. CleClean ban bleeleed vad valvelves ts thorhorougoughlyhly..

2.2. LoLow cw cononvvererteterr

charging pumpcharging pump

outputoutput

continuedcontinued

1.1. LoLow ow oil il lelevvelel..

2.2. SuSuctctioion scn screreen pen pluluggggeded..

3.3. Air Air leakleaks at s at pumpump inp intaktake hoe hose ase andnd

connections or collapsed hose.connections or collapsed hose.

4.4. DeDefefectctivive che charargiging png pumump.p.

1.1. FiFill ll to to propropeper r lelevevel.l.

2.2. ClCleaean sn sucuctition on scscrereenen..

3.3. TTighighten aten all coll connecnnectiotions or ns or repreplaclacee

hose if hose if necessarynecessary..

4.4. ReReplplacace ce chahargrgining pg pumump.p.

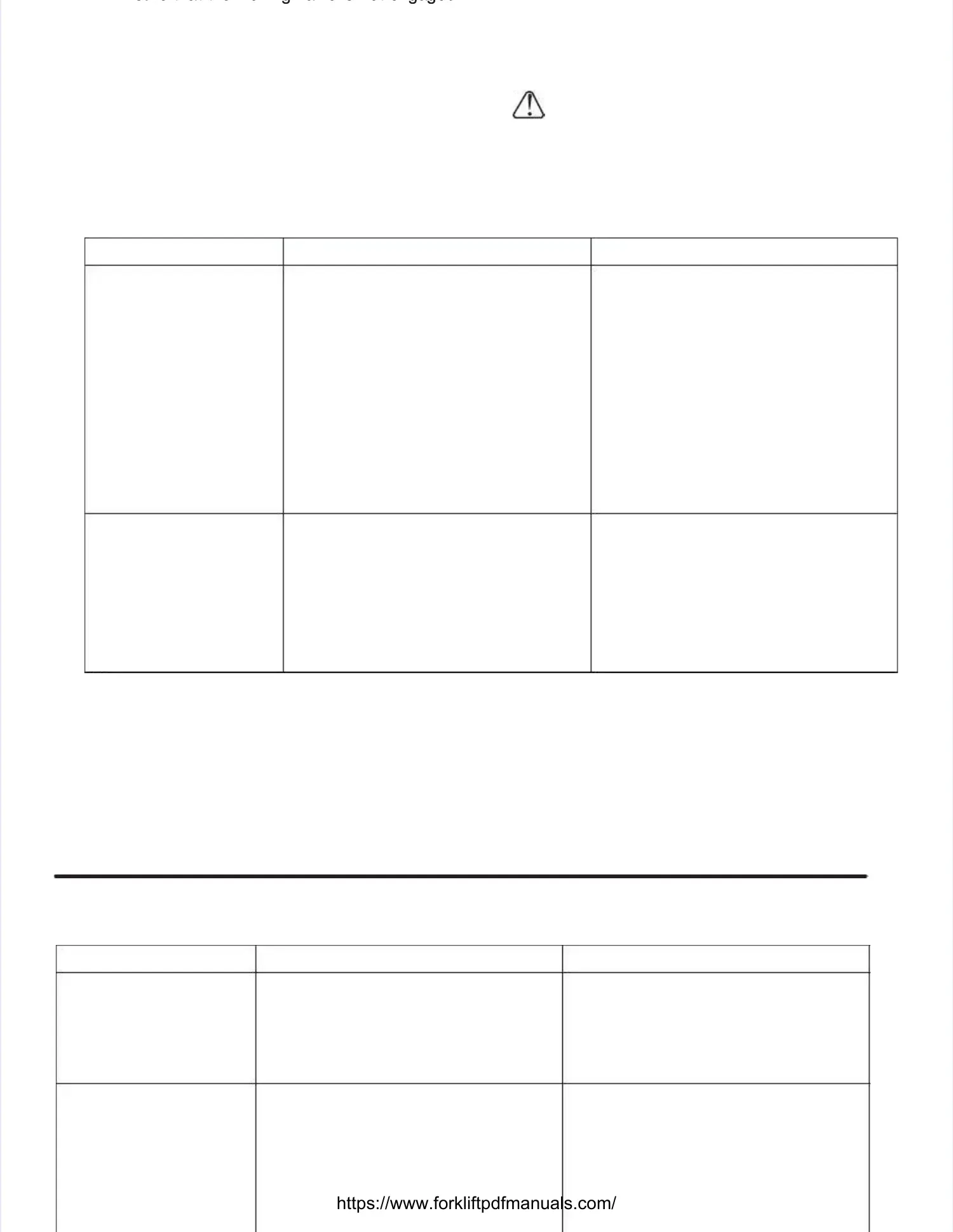

PPrroobblleemm CCaauussee CCoorrrreeccttiioonn

2.2. LoLow cw cononvevertrterer

charging pumpcharging pump

output (Continued)output (Continued)

5.5. CloCloggegged trd transansmismissiosion fin filtelterr..

6.6. DefDefectective ive prepressussure rre reguegulatlatoror..

5.5. RepReplaclace tre transansmismissiosion fin filtelterr..

6.6. RepReplaclace e or or reburebuild ild prepressussurere

regulator.regulator.

3.3. NoNoisisy y coconvnvererteterr

1.1. WoWorn rn cocoupupliling ng gegearars.s.

2.2. WoWorn rn chchargargining g pupumpmp..

3.3. WoWorn orn or dar damamageged bed bearariningsgs..

1.1. ReReplplacace ce coupoupliling gng geaearsrs..

2.2. ReReplplacace ce chahargirging ng pupumpmp..

3.3. A coA complmplete ete disdisassassembembly wly will ill bebe

necessary to determine whichnecessary to determine which

bearing is faulty.bearing is faulty.

Loading...

Loading...