TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

20A-220A-2

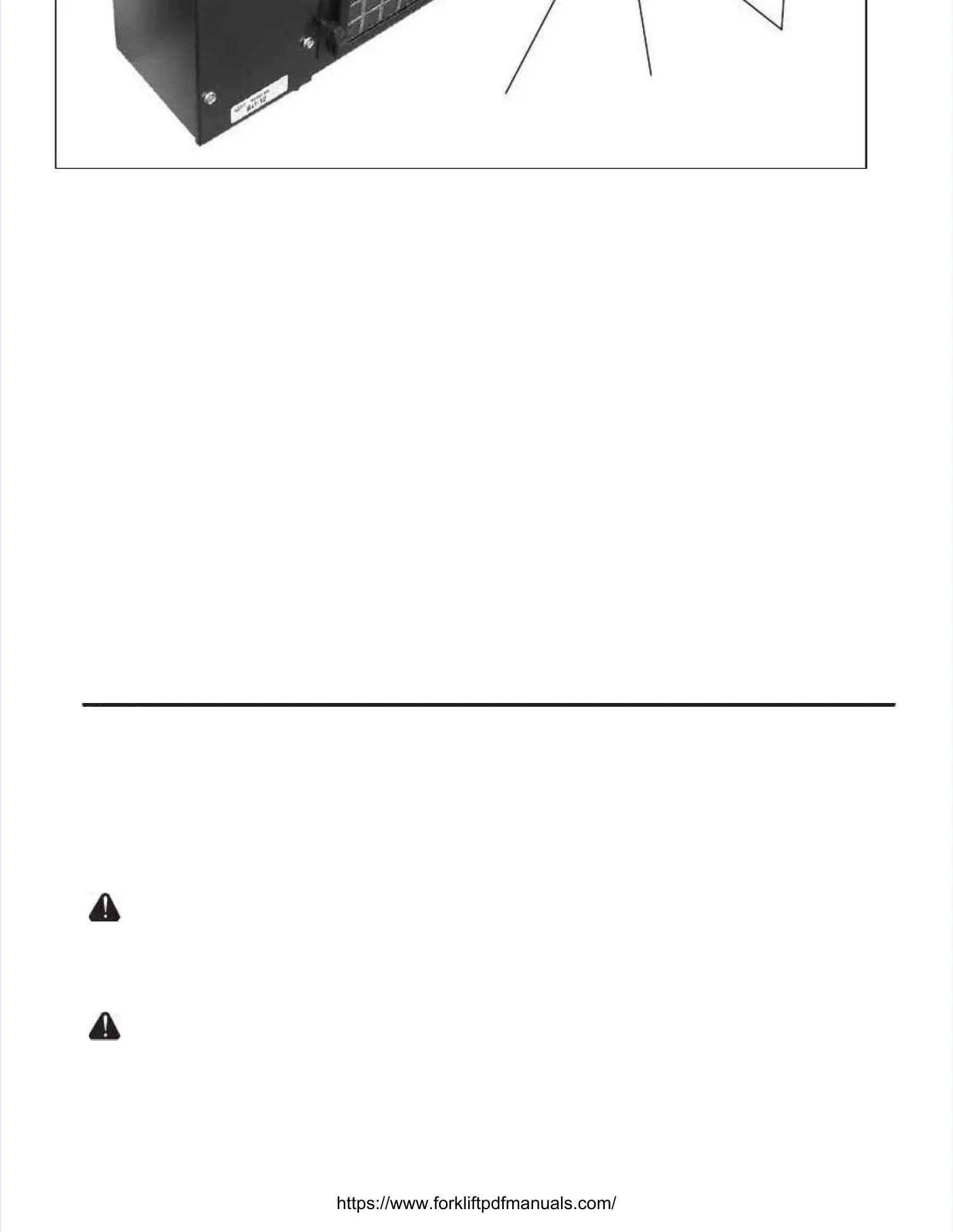

FILTERFILTER

COVERCOVER

FASTENERSFASTENERS

Illustration 20A-1. Illustration 20A-1. Air Conditioner Air Conditioner / Heater / Heater UnitUnit

Heater Shut-off Heater Shut-off VValvealve(Illustration 20A-1)(Illustration 20A-1).. TheThe

heater shut-off valve controls the circulation ofheater shut-off valve controls the circulation of

heated coolant through the air conditioning / heat-heated coolant through the air conditioning / heat-

er unit. er unit. AdditionallyAdditionally, there are t, there are two shut-off wo shut-off valves,valves,

located on the engine, that control the circulationlocated on the engine, that control the circulation

of heated coolant through the heating / defrostingof heated coolant through the heating / defrosting

circuit. circuit. All three shut-ofAll three shut-off valves must f valves must be fully openbe fully open

for maximum for maximum heating. heating. If any of If any of the shut-off the shut-off valvesvalves

are closed, there will be no circulation of heatedare closed, there will be no circulation of heated

coolant through the heating system.coolant through the heating system.

Refrigerant Hoses.Refrigerant Hoses. Periodically Periodically check check the hosesthe hoses

and fittings and fittings for chafing for chafing or cracking. or cracking. Replace asReplace as

conditions require.conditions require.

Cleaning and / or Changing The Air Condition-Cleaning and / or Changing The Air Condition-

er / Heater Unit Filterser / Heater Unit Filters (Illustration 20A-1)(Illustration 20A-1).. The The

air conditioner filters should be cleaned everyair conditioner filters should be cleaned every

3 months 3 months or as conditions or as conditions warrant. warrant. The filtersThe filters

must be replaced yearly or as conditions warrant.must be replaced yearly or as conditions warrant.

If filters are not cleaned regularly, they mayIf filters are not cleaned regularly, they may

become partially clogged with lint, dirt, grease orbecome partially clogged with lint, dirt, grease or

other debris. other debris. The filters The filters should be cshould be cleaned orleaned or

changed as changed as conditions warrant. conditions warrant. Perform the Perform the fol-fol-

lowing procedures to remove filters for cleaning orlowing procedures to remove filters for cleaning or

replacement:replacement:

1.1. RemovRemove file filter ter covercovers frs from tom the aihe air conr conditionditioner /er /

heater unit’s housing by removing fasteners.heater unit’s housing by removing fasteners.

2.2. RemovRemove fie filters lters from from filtefilter covr covers aers and cnd clean lean withwith

low pressure airlow pressure air. . Replace old filters Replace old filters with newwith new

filters if filters are damaged.filters if filters are damaged.

3.3. InstaInstall the fll the filterilters in ts in the filhe filter coter covers vers and and secsecureure

filter covers to air conditioner / heater unit withfilter covers to air conditioner / heater unit with

fasteners.fasteners.

Inspection.Inspection. In the In the event of event of a cooling a cooling problem,problem,

perform the following inspection procedures.perform the following inspection procedures.

Death or serious injury couldDeath or serious injury could

result from result from a runaway truck. a runaway truck. Park the truck Park the truck onon

a hard, level surface, apply the parking brakea hard, level surface, apply the parking brake

and block the wheels in both directions toand block the wheels in both directions to

prevent movement of the truck.prevent movement of the truck.

Rotating fan and belts canRotating fan and belts can

cause severe injury. cause severe injury. Stay clear Stay clear of fan of fan andand

belts when engine is running.belts when engine is running.

1.1. CheCheck thck the come comprepressossor drivr drive belt te belt tensension anion andd

pulley alignment. pulley alignment. TTension on the drive ension on the drive beltbelt

should be such that a firm push with the thumbshould be such that a firm push with the thumb

at a point midway between the two pulleys willat a point midway between the two pulleys will

deflect the belt deflect the belt approximately 3/8” (9.approximately 3/8” (9.5 mm). 5 mm). IfIf

the deflection of the belt is more than 3/8” (9.5the deflection of the belt is more than 3/8” (9.5

mm), adjust the belt tension.mm), adjust the belt tension.

22 CheCheck thck the cone condendenser fser for debor debris aris and clnd clean ifean if

engage the clutch of the compressor (refer toengage the clutch of the compressor (refer to

DrierDrierin this section).in this section).

7.7. CheCheck thck the air coe air conditnditionioning hoing hoses ases and fitnd fittintingsgs

for leaks. for leaks. If a leak If a leak is detected, is detected, the refrigerantthe refrigerant

must be recovered prior to making repairs.must be recovered prior to making repairs.

NOTE:NOTE: The Clean Air The Clean Air Act, passed Act, passed in 1992, speci-in 1992, speci-

fies that anyone who works on vehicle air condi-fies that anyone who works on vehicle air condi-

tioning systems must be certified by an EPAtioning systems must be certified by an EPA

approved approved agencyagency..

8.8. For aFor any fny further urther repairrepairs, cs, contacontact a t a certicertified fied airair

conditioning repair technician.conditioning repair technician.

https://www.forkliftpdfmanuals.com/

Loading...

Loading...