22-1522-15TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

ssteetee g sg s otot estoesto ed ated at t st s po t,po t, ep acep acee

the orbitrol.the orbitrol.

Troubleshooting Common Brake Problems.Troubleshooting Common Brake Problems.

Should brake pressure drop below 1,500 psi (104Should brake pressure drop below 1,500 psi (104

bar), a warning will be generated by the TICS.bar), a warning will be generated by the TICS.

Should the brake pressure continue to drop atShould the brake pressure continue to drop at

1,000 psi (69 bar), the parking brake will automati-1,000 psi (69 bar), the parking brake will automati-

cally applycally apply. . The parking The parking brake is brake is spring-appliedspring-applied

and hydraulic pressure to release (1,250 psi / 86and hydraulic pressure to release (1,250 psi / 86

bar minimum).bar minimum).

1.1. StStarart t ththe te truruckck..

2.2. The BThe Brakrake pree pressussure care can be obn be obtaitained fned from trom thehe

TICS module display (refer to the Trans-TICS module display (refer to the Trans-

mission Measure Group list illustration ofmission Measure Group list illustration of TICSTICS

inin Section 6Section 6).).

3.3. TTo enso ensure ture the prehe pressure ssure transdtransducerucer, w, whichhich

communicates brake pressure to the TICS, iscommunicates brake pressure to the TICS, is

5.5. ShuShut the trt the truck ouck off anff and turn td turn the ignhe ignitiition swon switcitchh

to it’s to it’s ignition position (1st ignition position (1st click). click). Continue toContinue to

monitor the brake pressure from the TICSmonitor the brake pressure from the TICS

module module displaydisplay..

Death or serious injury couldDeath or serious injury could

result from removal of a component underresult from removal of a component under

pressure. pressure. The brake The brake circuits storcircuits store pressuree pressure

after the enafter the engine has gine has been shut been shut down. down. AlwaysAlways

bleed the brake pressure to 0 psi prior tobleed the brake pressure to 0 psi prior to

removal of any brake component.removal of any brake component.

6.6. Shut Shut off off the the engineengine. . TuTurn rn the the ignitiignition on switcswitch th too

it’s ignition it’s ignition position (1st position (1st click). click). Bleed the brakeBleed the brake

pressure to zero by repeatedly depressing onepressure to zero by repeatedly depressing one

of the service brake pedals and monitoring theof the service brake pedals and monitoring the

brake pressure at the TICS module display.brake pressure at the TICS module display.

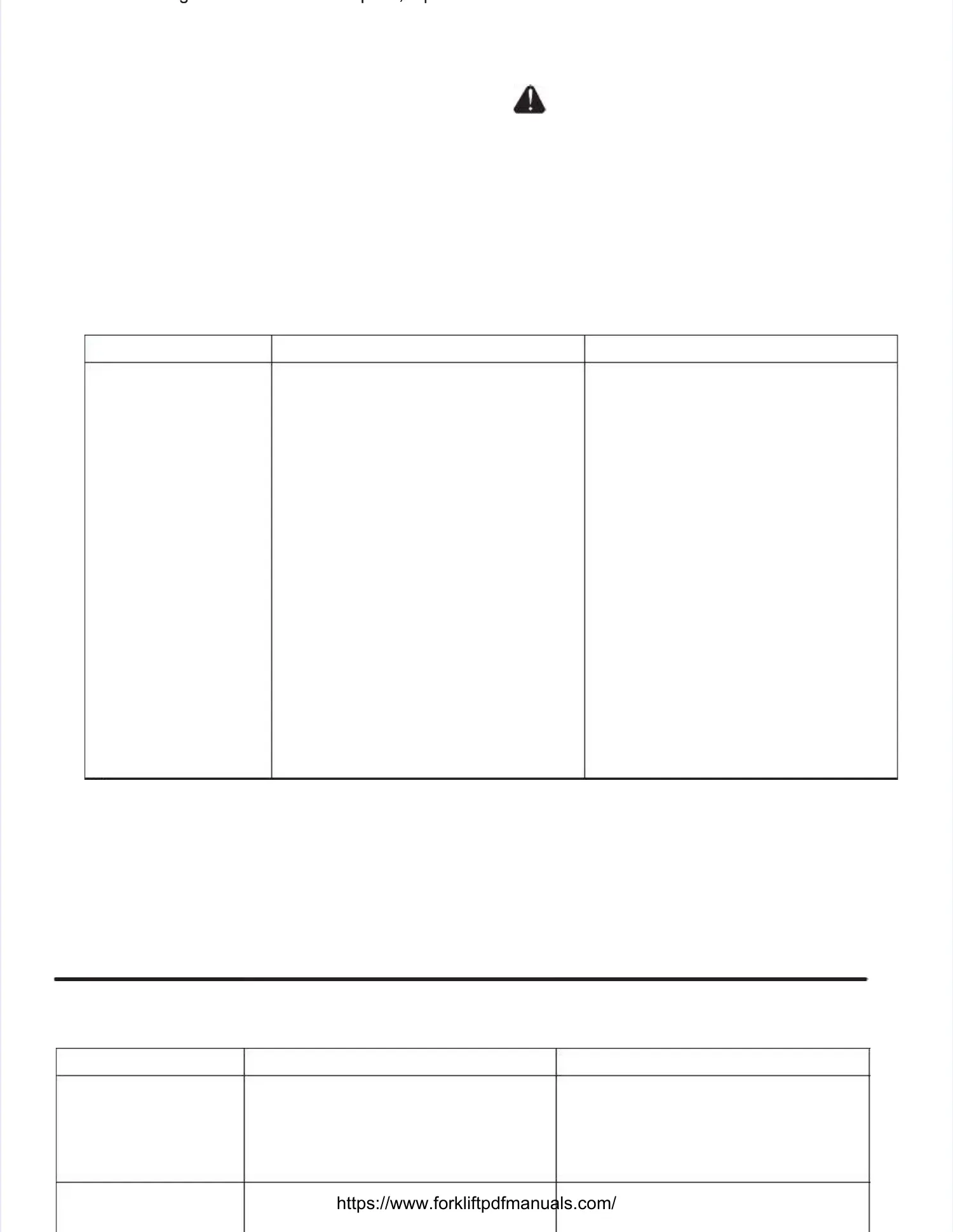

PPrroobblleemm CCaauussee CCoorrrreeccttiioonn

1.1. No No LiLift ft / / LoLowewer /r /

Tilt in / Tilt outTilt in / Tilt out

continuedcontinued

1.1. OpeOperatrator ior is nos not st seateated ied in thn the ope oper-er-

ators seat.ators seat.

2.2. LoLow piw pilolot prt presessusurere..

3.3. No hNo hydydraraululic fic fluluid fid floloww..

4.4. IncIncorrorrect ect prepressussure sere settitting of ng of thethe

main relief (RV1).main relief (RV1).

5.5. DefDefectective ive maimain rn relielief ef (R(RV1)V1)..

6.6. IncIncorrorrect ect prepressussure sre settetting oing of thf thee

accessory valve’s main relief.accessory valve’s main relief.

7.7. DefDefectective aive acceccessossory vary valvelve’s ’s maimainn

relief.relief.

8.8. DefDefectective ive LogLogic Cic Contontrol rol (LC(LC3).3).

9.9. DeDefefectctivive me maiain pn pumump.p.

1.1. RetReturn urn to to the the operoperatoators rs seaseat.t.

2.2. IsIsololatate e and and reprepaiairr..

3.3. IsIsololatate e and and reprepaiairr..

44.. AAddjjuusstt..

55.. RReeppllaaccee..

66.. AAddjjuusstt..

77.. RReeppllaaccee..

88.. RReeppllaaccee..

99.. RReeppllaaccee..

Loading...

Loading...