27-327-3TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

NOTES:NOTES:

Clearance at each position should be betweenClearance at each position should be between

1/16 inch (1.6 mm) and 1/32 inch (.8 mm).1/16 inch (1.6 mm) and 1/32 inch (.8 mm).

Repeat the above procedure if the clearance isRepeat the above procedure if the clearance is

not as specified. not as specified. Shims should be Shims should be divided asdivided as

evenly as possible between the slide bearings.evenly as possible between the slide bearings.

Replace any slide bearing blocks that becomeReplace any slide bearing blocks that become

cracked, damaged, or worn to 1 - 3/4 inchescracked, damaged, or worn to 1 - 3/4 inches

(44.5 mm)(44.5 mm)thickness (See Illustration 27-3).thickness (See Illustration 27-3).

TroubleshootingTroubleshooting

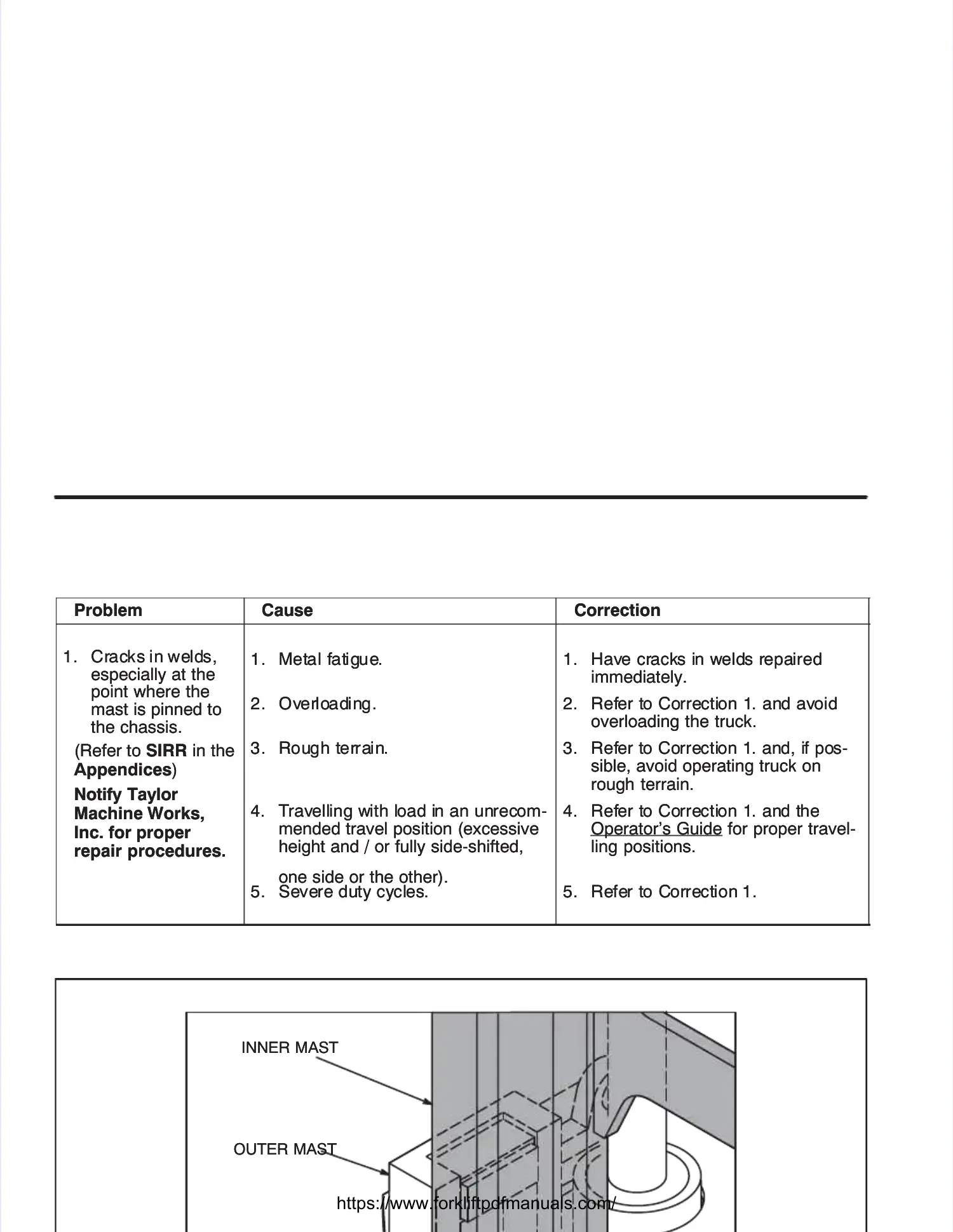

PPrroobblleemm CCaauussee CCoorrrreeccttiioonn

1.1. CrCracacks ks in in weweldlds,s,

especially at theespecially at the

point where thepoint where the

mast is pinned tomast is pinned to

the chassis.the chassis.

(Refer to(Refer to SIRRSIRRin thein the

AppendicesAppendices))

Notify TaylorNotify Taylor

Machine Works,Machine Works,

Inc. for properInc. for proper

repair procedures.repair procedures.

1.1. MMetetal fal fatatigigueue..

2.2. OvOvererloloadadining.g.

3.3. RRouough tgh tererrarainin..

4.4. TTravravellelling wing with lith load ioad in an unn an unrecrecom-om-

mended travel position (excessivemended travel position (excessive

height and / or fully side-shifted,height and / or fully side-shifted,

one side or the other).one side or the other).

5.5. SeSevevere re duduty ty cycyclcleses..

1.1. HavHave cre crackacks is in wn weldelds rs repaepairedired

immediately.immediately.

2.2. RefRefer ter to Coo Correrrectiction 1on 1. an. and avd avoidoid

overloading the truck.overloading the truck.

3.3. RefRefer ter to Coo Correrrectiction 1on 1. an. and, id, if pof pos-s-

sible, avoid operating truck onsible, avoid operating truck on

rough terrain.rough terrain.

4.4. RefRefer ter to Coo Correrrectiction 1on 1. an. and td thehe

Operator’s Guide for proper travel-Operator’s Guide for proper travel-

ling positions.ling positions.

5.5. ReRefefer tr to Co Cororrerectction ion 1.1.

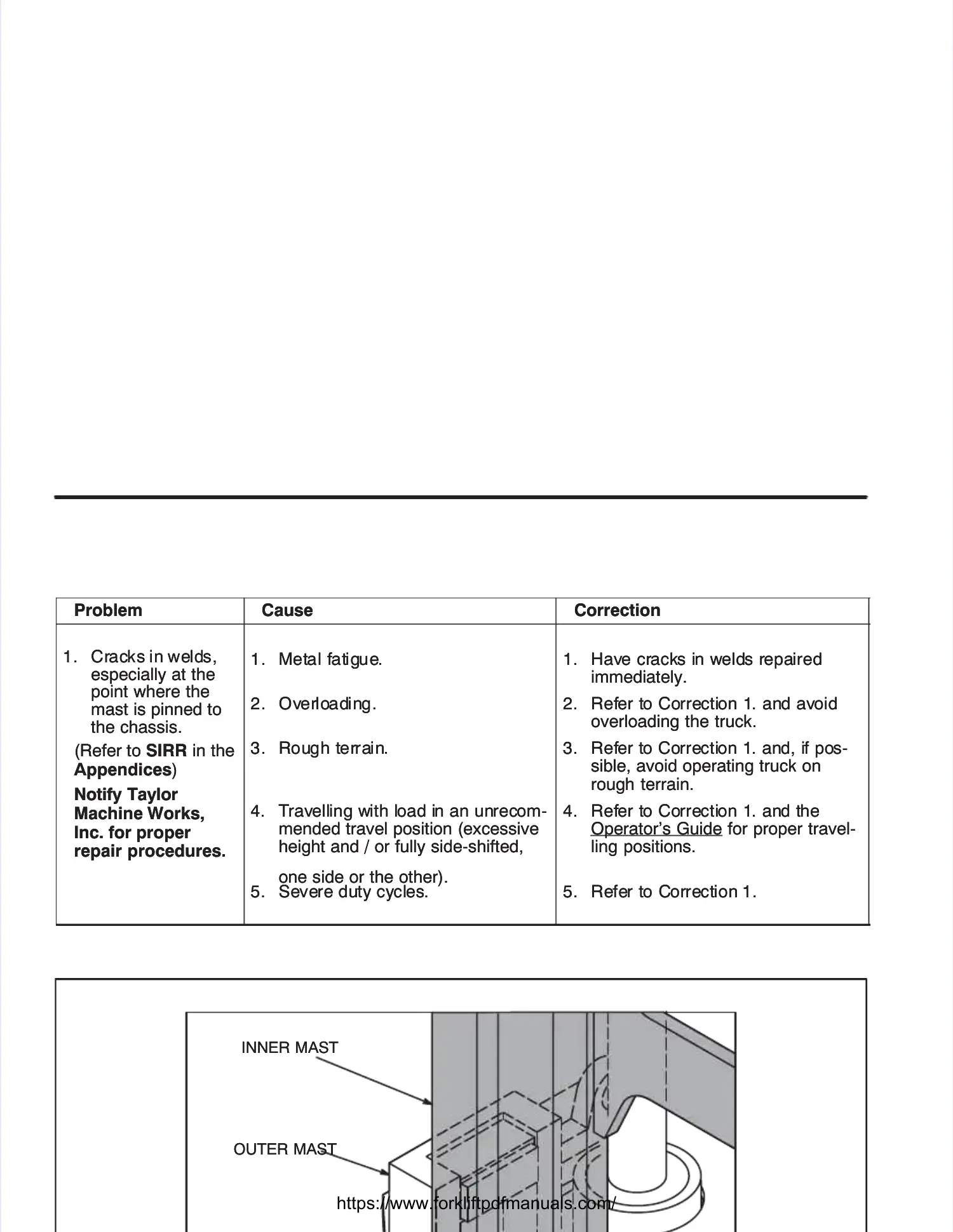

OUTER MASTOUTER MAST

INNER MASTINNER MAST

Loading...

Loading...