Section 28

Section 28

CarriageCarriage

Introduction.Introduction. Described in this section is the main-Described in this section is the main-

tenance required for the standard “C” carriage,tenance required for the standard “C” carriage,

optional fork positioning, and optional side shiftoptional fork positioning, and optional side shift

carriage.carriage.

NOTE:NOTE: Some trucks Some trucks may be may be equipped with equipped with bothboth

fork positioning and side shifting capabilities.fork positioning and side shifting capabilities.

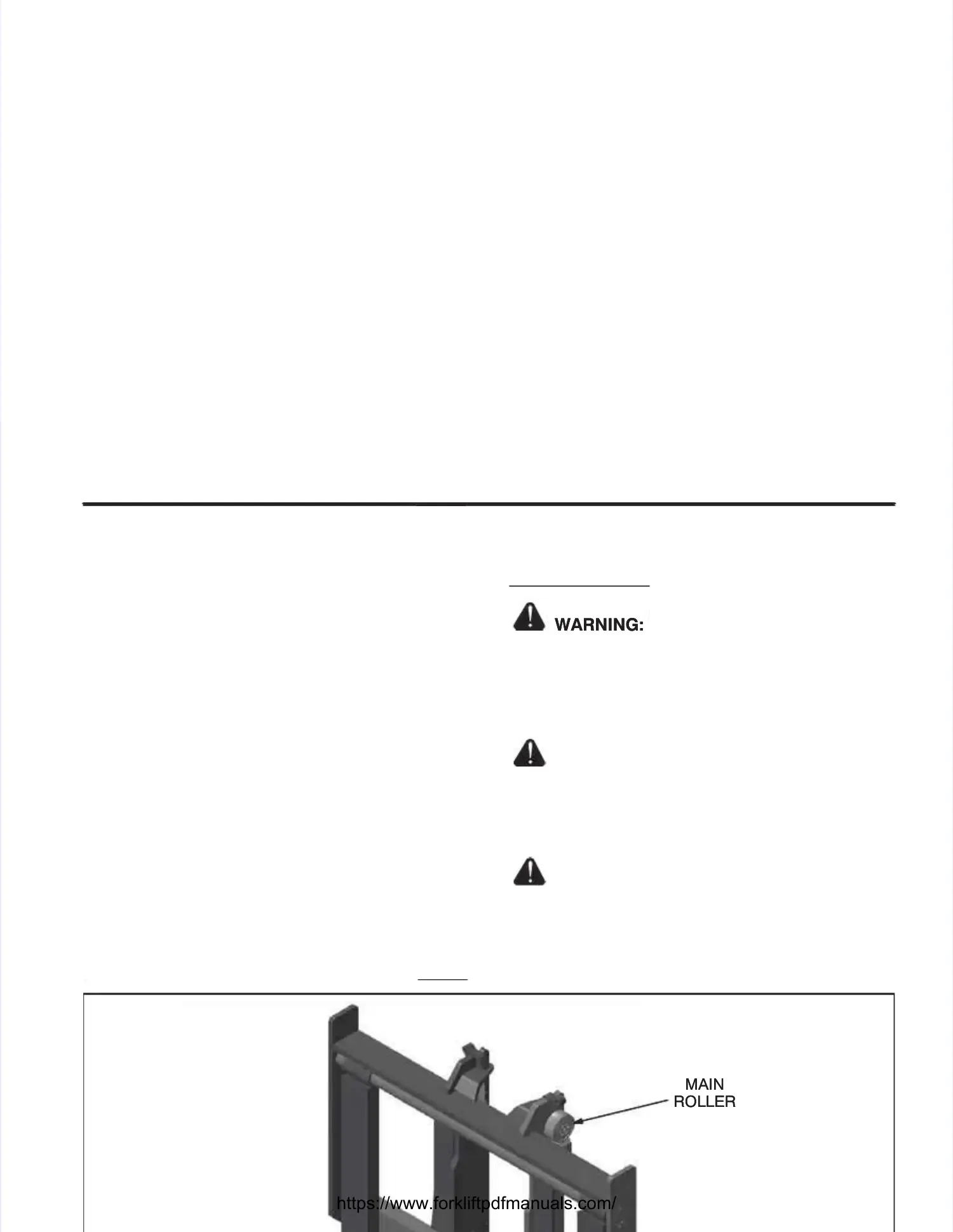

Major Components.Major Components. The carriage consists of twoThe carriage consists of two

forks, fork pin, main rollers, slide bearing blocks,forks, fork pin, main rollers, slide bearing blocks,

and two fork positioner cylinders / side shift cylin-and two fork positioner cylinders / side shift cylin-

der (if equipped).der (if equipped).

Structural Inspection, Reporting, and RepairStructural Inspection, Reporting, and Repair

ProcedureProcedure(Refer to(Refer to SIRRSIRRin thein the AppendicesAppendices))..

Follow the OSHA rules, 29 CFR, 1910.178 (Q)(1),Follow the OSHA rules, 29 CFR, 1910.178 (Q)(1),

(5), & (7) which require inspecting industrial trucks(5), & (7) which require inspecting industrial trucks

daily before being placed in service, removingdaily before being placed in service, removing

trucks from service if cracks are found, and mak-trucks from service if cracks are found, and mak-

ing repairs only if authorized by the manufacturer.ing repairs only if authorized by the manufacturer.

If trucks are used on a round-the-clock basis, theyIf trucks are used on a round-the-clock basis, they

shall be examined shall be examined after each safter each shift. hift. OSHA 29 CFROSHA 29 CFR

1910.178 (p)(1) requires that trucks in need of1910.178 (p)(1) requires that trucks in need of

repair be taken repair be taken out of service. out of service. Refer to the Refer to the SafetySafety

Check 2nd Edition for OSHA rules.Check 2nd Edition for OSHA rules.

Periodic inspection isPeriodic inspection is

required to detect fatigue cracks that haverequired to detect fatigue cracks that have

grown to a significant size in order to avoidgrown to a significant size in order to avoid

serious failure of the structural weldment.serious failure of the structural weldment.

When a crack is found, the truck must beWhen a crack is found, the truck must be

immediately taken out of service and repaired.immediately taken out of service and repaired.

Under no circumstances,Under no circumstances,

without prior written approval without prior written approval from Taylorfrom Taylor

Machine Works, Inc. Engineering Department,Machine Works, Inc. Engineering Department,

should the should the carriage assembly carriage assembly be modifiedbe modified. . AsAs

per OSHA 29 CFR1910.178 (a) (4).per OSHA 29 CFR1910.178 (a) (4).

If the fatigue crack is allowedIf the fatigue crack is allowed

to grow, catastrophic failure could occur in to grow, catastrophic failure could occur in thethe

mast assembly or other welded componentsmast assembly or other welded components

causing serious injury to personnel and / orcausing serious injury to personnel and / or

property.property.

MAINMAIN

ROLLERROLLER

Loading...

Loading...