A-3A-3TX / TXH / TXB 180S - 400L (Rev. 4/23/07)TX / TXH / TXB 180S - 400L (Rev. 4/23/07)

tude, these cracks will growtude, these cracks will grow. . This is known asThis is known as

fatigue crack fatigue crack growth. growth. No matter No matter how low thehow low the

stress levels are kept some fatigue crack growthstress levels are kept some fatigue crack growth

will occur in all welded structures.will occur in all welded structures.

Eventually, these fatigue cracks will become largeEventually, these fatigue cracks will become large

enough to be detectable by nondestructive testingenough to be detectable by nondestructive testing

methods, i.e. VT, MT, DPT, or UT.methods, i.e. VT, MT, DPT, or UT.

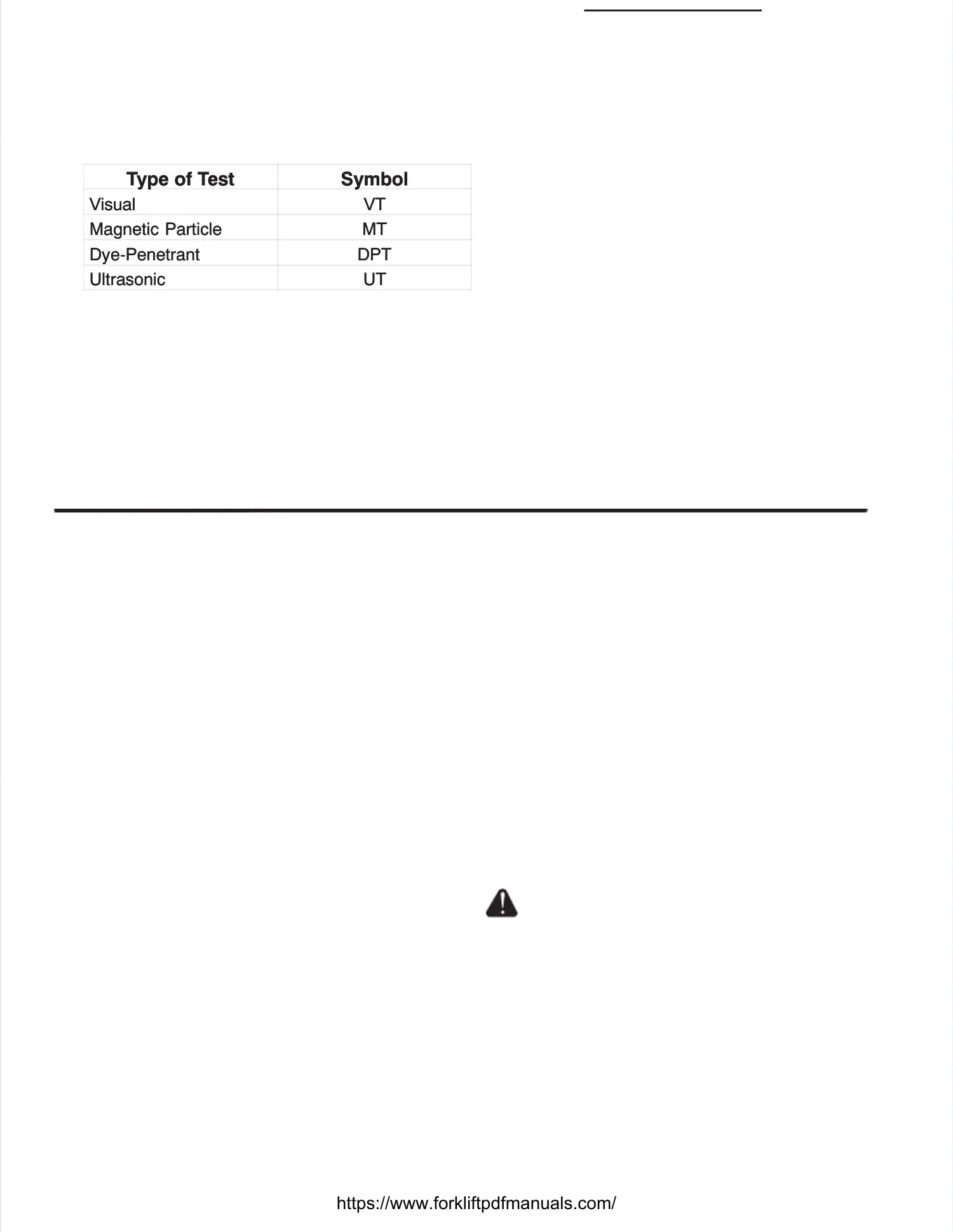

Abbreviations.Abbreviations. Basic Basic TTesting Symbolsesting Symbols

TTyyppe e oof f TTeesstt SSyymmbbooll

VViissuuaall VVTT

MMaaggnneettiic c PPaarrttiiccllee MMTT

DDyyee--PPeenneettrraanntt DDPPTT

UUllttrraassoonniicc UUTT

you haveyou have prior written approvalprior written approvalof the manufac-of the manufac-

turer for such changes.turer for such changes.

Test ProceduresTest Procedures

1.1. Visual (VT).Visual (VT). Dirt and Dirt and grease should grease should bebe

removed from the surface by wiping with a rag.removed from the surface by wiping with a rag.

One should look for cracked paint and rustOne should look for cracked paint and rust

showing through showing through the paint. the paint. Also, look Also, look forfor

movement at bolted joints, irregular lines inmovement at bolted joints, irregular lines in

welds or dents, or deformations in the materi-welds or dents, or deformations in the materi-

al. al. Proper lighting is Proper lighting is required in order required in order toto

obtain satisfactory results.obtain satisfactory results.

2.2. Magnetic Particle (MT).Magnetic Particle (MT). The The test test surfacesurface

must be free of loose rust, scale, moisture,must be free of loose rust, scale, moisture,

and painted surfaces must be cleaned at alland painted surfaces must be cleaned at all

points of points of electrode contactelectrode contact. . Grinding, brush-Grinding, brush-

ing, or blasting do not affect results of thising, or blasting do not affect results of this

method of testing in most instances.method of testing in most instances.

A magnetic field can A magnetic field can be applied to be applied to the testthe test

material with:material with:

a.a. PePermrmananenent mat magngnetet..

b.b. YYoke woke whichich is an elh is an electectromromagnagnet tyet type ofpe of

device.device.

c.c. PasPassinsing higg high amh amperperage cage currurrent ent thrthrougoughh

the part.the part.

3.3. Dye-Penetrant (DPT)Dye-Penetrant (DPT). . The tesThe test surfact surface muste must

be thoroughly be thoroughly cleaned and cleaned and dried. dried. This can This can bebe

done with chemical solvents, vapor degreas-done with chemical solvents, vapor degreas-

ing, or by ing, or by mechanical methods. mechanical methods. HoweverHowever,,

cleaning mechanically, such as grinding, blast-cleaning mechanically, such as grinding, blast-

ing, or wire-brushing, might prove detrimentaling, or wire-brushing, might prove detrimental

to the test because surface discontinuities canto the test because surface discontinuities can

be masked by cold working of the surface.be masked by cold working of the surface.

Therefore, mechanical cleaning methods mustTherefore, mechanical cleaning methods must

be kept to a minimum.be kept to a minimum.

One of the following type penetrants should beOne of the following type penetrants should be

used in conjunction with the proper procedureused in conjunction with the proper procedure

to get satisfactory results:to get satisfactory results:

a.a. WWatater ser sololububle pele penenetrtranantt

b.b. PosPost t emuemulsilsifiafiable ble penpenetretrantant

c.c. SoSolvlvenent remt removovabable pele penenetrtranantt

Follow the directions supplied with the dye-Follow the directions supplied with the dye-

penetrant for best results.penetrant for best results.

4.4. Ultrasonic (UT).Ultrasonic (UT). TTesting should be esting should be done indone in

accordance with AWS D1.1 approved meth-accordance with AWS D1.1 approved meth-

ods.ods.

Frequency of Inspection.Frequency of Inspection. There There are are three three (3)(3)

levels of inspection:levels of inspection:

two years or 6,000 hours, whichever is sooner,two years or 6,000 hours, whichever is sooner,

thereafter. thereafter. These inspectThese inspections should ions should be per-be per-

formed by qualified maintenance personnel.formed by qualified maintenance personnel.

NOTE:NOTE: Duty cycles Duty cycles vary from vary from extremely severeextremely severe

(capacity loads, high frequency of loading, rough(capacity loads, high frequency of loading, rough

yards, etc.) to very light yards, etc.) to very light (partial capacities, few(partial capacities, few

load cycles, good yard load cycles, good yard conditions, etc.). conditions, etc.). DutyDuty

cycle directly affects product life and maintenancecycle directly affects product life and maintenance

requirements. requirements. Depending on Depending on the quality and the quality and thor-thor-

oughness of the daily inspections and the serviceoughness of the daily inspections and the service

experience of the vehicle, the three-month visualexperience of the vehicle, the three-month visual

inspection interval and inspection interval and the full-scale the full-scale inspectioninspection

interval may be interval may be adjusted (increased or adjusted (increased or decreased)decreased)

to levels appropriate for an individual vehicle dutyto levels appropriate for an individual vehicle duty

cycle.cycle.

Reporting Procedure.Reporting Procedure. TTaylor Machine Waylor Machine Works,orks,

Inc. should receive reports of the results of anyInc. should receive reports of the results of any

inspections.inspections.

Photocopy a sketch from your maintenance manu-Photocopy a sketch from your maintenance manu-

al, make your own sketch, or photograph, andal, make your own sketch, or photograph, and

show indication of crack if any are evident, statingshow indication of crack if any are evident, stating

the following:the following:

1.1. LocatiLocation (rion (right, lght, left, eft, innerinner, out, outerer, mac, machine shine sideide

etc.);etc.);

2.2. SiSize ze of of ccrarackck;;

3.3. ExExtetent nt of of crcracack;k;

a.a. In In ttoe oe of of wweleld;d;

Loading...

Loading...