A-17A-17

(Rev. 3/96)(Rev. 3/96)

p gp g

the fork carrier including bolt type mountings andthe fork carrier including bolt type mountings and

forged upper mounting arrangements for hookforged upper mounting arrangements for hook

and shaft type and shaft type carriages. carriages. The forks shall The forks shall not benot be

returned to service if surface cracks are detected.returned to service if surface cracks are detected.

The straightness of the upper face of the bladeThe straightness of the upper face of the blade

and the front face of the shank shall be checked.and the front face of the shank shall be checked.

If the deviation from straightness exceeds 0.5% ofIf the deviation from straightness exceeds 0.5% of

the length of the blade and/or the height of thethe length of the blade and/or the height of the

shank, respectively, the fork shall not be returnedshank, respectively, the fork shall not be returned

to service until it has been repaired.to service until it has been repaired.

repaired for continued use, and the repairs shallrepaired for continued use, and the repairs shall

only be carried out by such parties.only be carried out by such parties.

It is not recommended that surface cracks or wearIt is not recommended that surface cracks or wear

be repaired be repaired by welding. by welding. When repairs When repairs necessitat-necessitat-

ing resetting are required, the fork shall subse-ing resetting are required, the fork shall subse-

quently be subjected to an appropriate heat treat-quently be subjected to an appropriate heat treat-

ment, as necessary.ment, as necessary.

A fork that A fork that has undergone repairs has undergone repairs shall only beshall only be

returned to service after being submitted to, andreturned to service after being submitted to, and

passing, the passing, the test procedures. test procedures. The test The test load shallload shall

correspond to 2.5 times the rated capacity markedcorrespond to 2.5 times the rated capacity marked

on the fork.on the fork.

DDFF

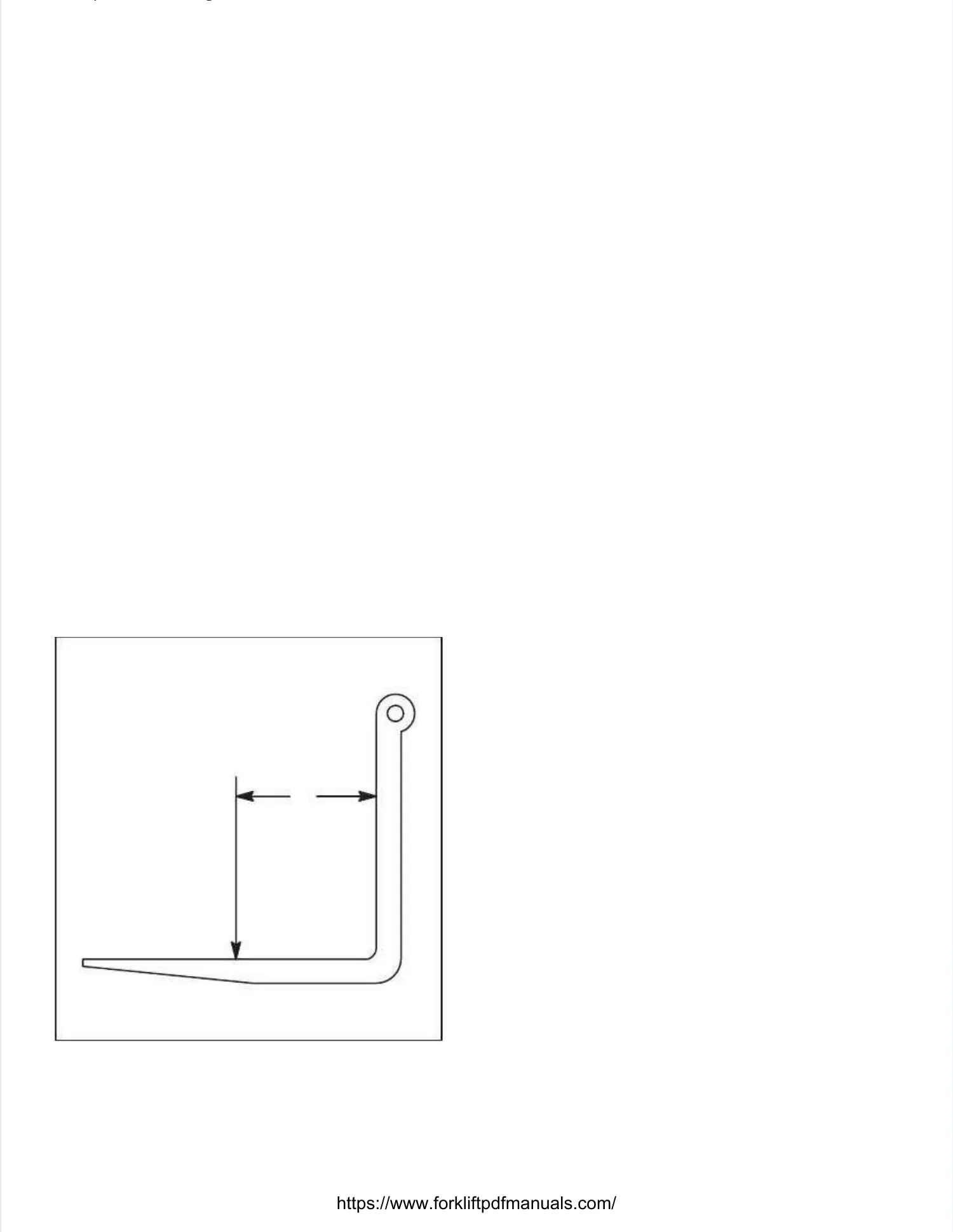

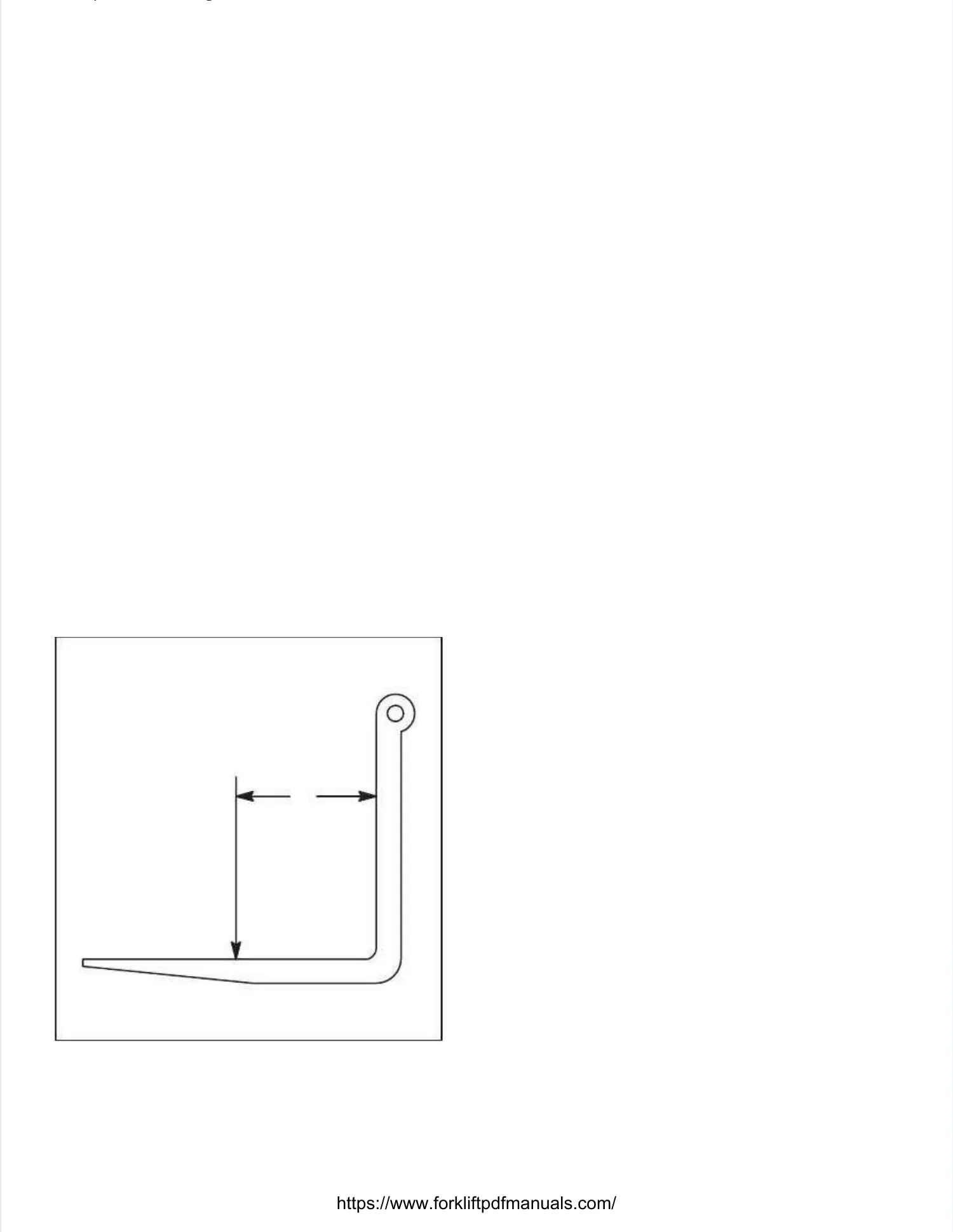

Illustration Illustration 1. 1. TyTypical Fpical Forkork

Fork strength shall permit the following loadingFork strength shall permit the following loading

and method of test.and method of test.

1.1. The tThe test lest load F soad F shalhall be apl be applieplied to it d to it at that thee

applicable distance D from the front face of theapplicable distance D from the front face of the

fork arm shank (see Illustration 1).fork arm shank (see Illustration 1).

2.2. The fThe fork aork arm shrm shall ball be rese restratraineined in a mad in a mannennerr

identical to that used on the forklift truck.identical to that used on the forklift truck.

Loading...

Loading...