A-21A-21

TX / TXH / TXB 180S - 400L (4/07)TX / TXH / TXB 180S - 400L (4/07)

cyclic stress necessary)cyclic stress necessary)

from hostile environment byfrom hostile environment by

lubricating more frequentlylubricating more frequently

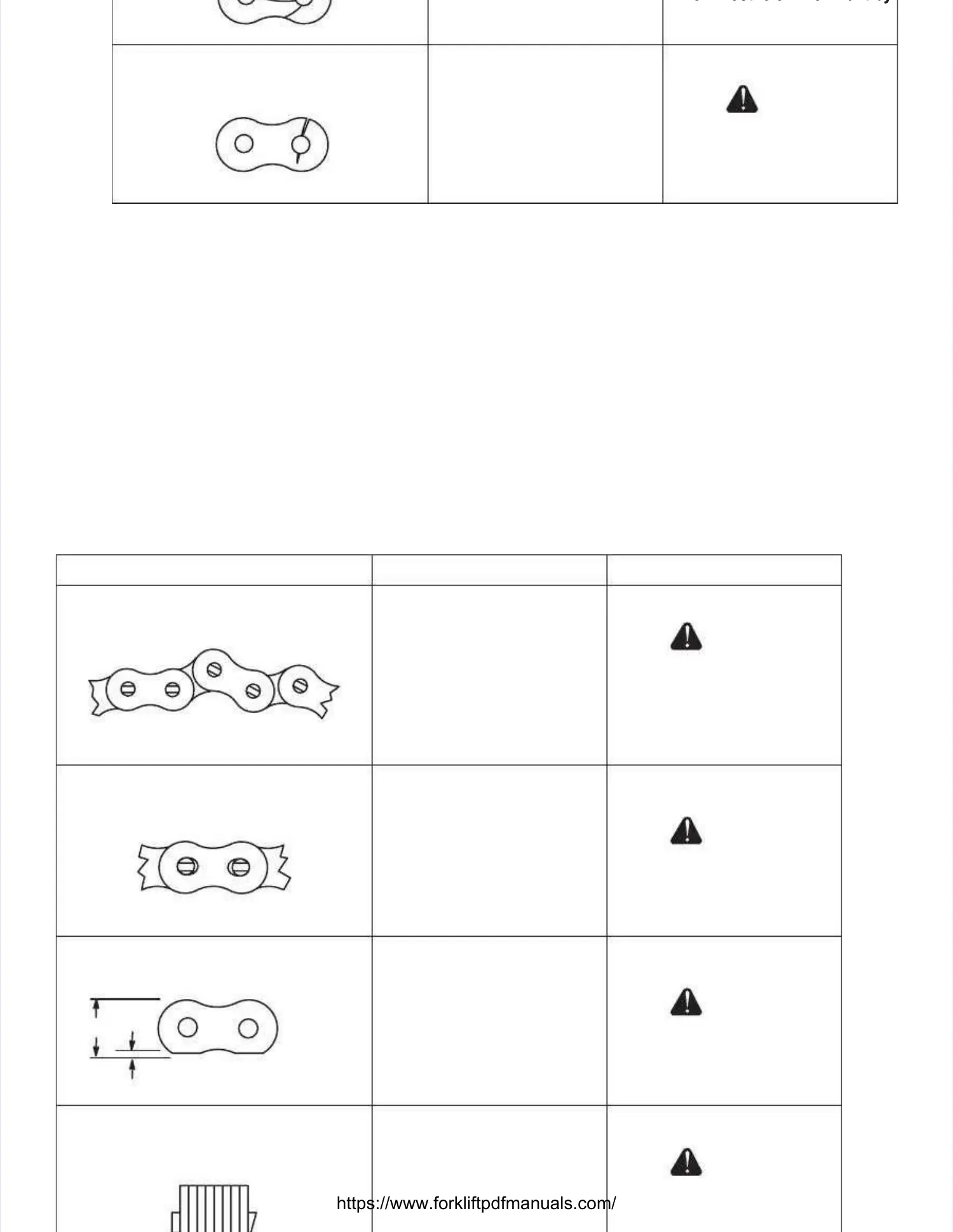

5. Cracked Plates (Corrosion Fatigue)5. Cracked Plates (Corrosion Fatigue)

Perpendicular to Pitch Line, plus rustPerpendicular to Pitch Line, plus rust

or other evidence of chemicalor other evidence of chemical

corrosioncorrosion

Corrosive environment andCorrosive environment and

cyclic motion (chain undercyclic motion (chain under

cyclic operation)cyclic operation)

Replace Replace chain chain and and protectprotect

from hostile environment byfrom hostile environment by

lubricating more frequentlylubricating more frequently

AAppppeeaarraanncce e aanndd//oor r SSyymmppttoomm PPrroobbaabblle e CCaauussee CCoorrrreeccttiioonn

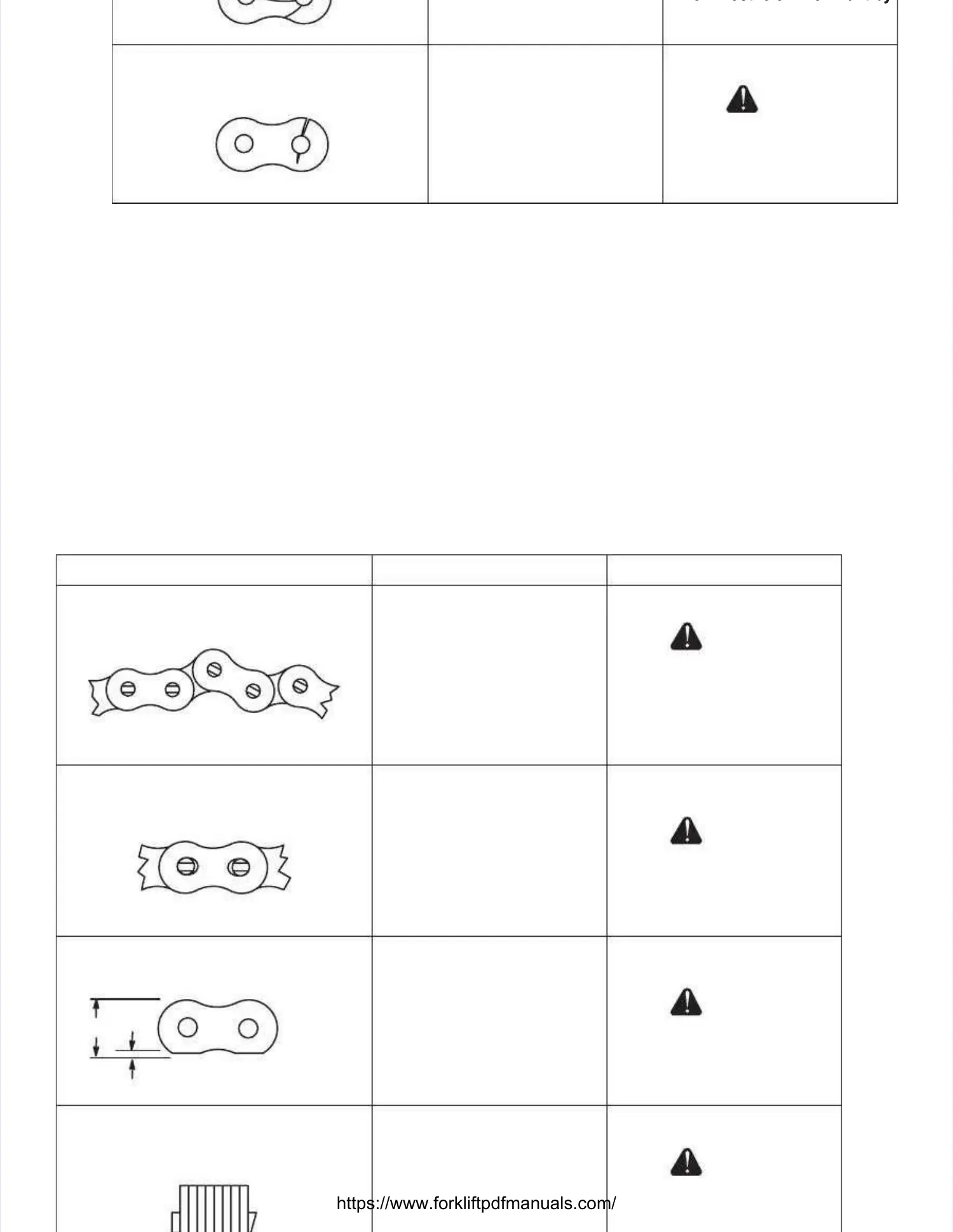

6. Tight Joints6. Tight Joints

Dirt or foreign substanceDirt or foreign substance

packed in jointspacked in joints

Corrosion and rustCorrosion and rust

Bent pinsBent pins

Replace chainReplace chain

Replace chainReplace chain

Clean and relubeClean and relube

7. Enlarged Holes7. Enlarged Holes

High overload, dropping andHigh overload, dropping and

catching loadcatching load

Replace chain and correctReplace chain and correct

cause of overloadcause of overload

8. Worn Contour (Edge Wear)8. Worn Contour (Edge Wear)

5% of H5% of H

HH

Normal wear on sheave bearingNormal wear on sheave bearing

areaarea

Abnormal wear, Abnormal wear, rubbing onrubbing on

rollerroller

Replace chain and correctReplace chain and correct

cause of overloadcause of overload

Check chain roller bearingCheck chain roller bearing

Replace chain when wearReplace chain when wear

reaches 5% of H.reaches 5% of H.

9. Worn Surfaces on Outside Links9. Worn Surfaces on Outside Links

or Pin Headsor Pin Heads

Misalignment, rubbing on rollerMisalignment, rubbing on roller

flangesflanges

Check alignment ofCheck alignment of

anchors, chain rollersanchors, chain rollers

d h i ll id h i ll i

Loading...

Loading...