For Support Visit· support.technocnc.com or Call: (631) 648-7481

47

HDS User Manual

(HTT06291133)

V. Machine Lubrication

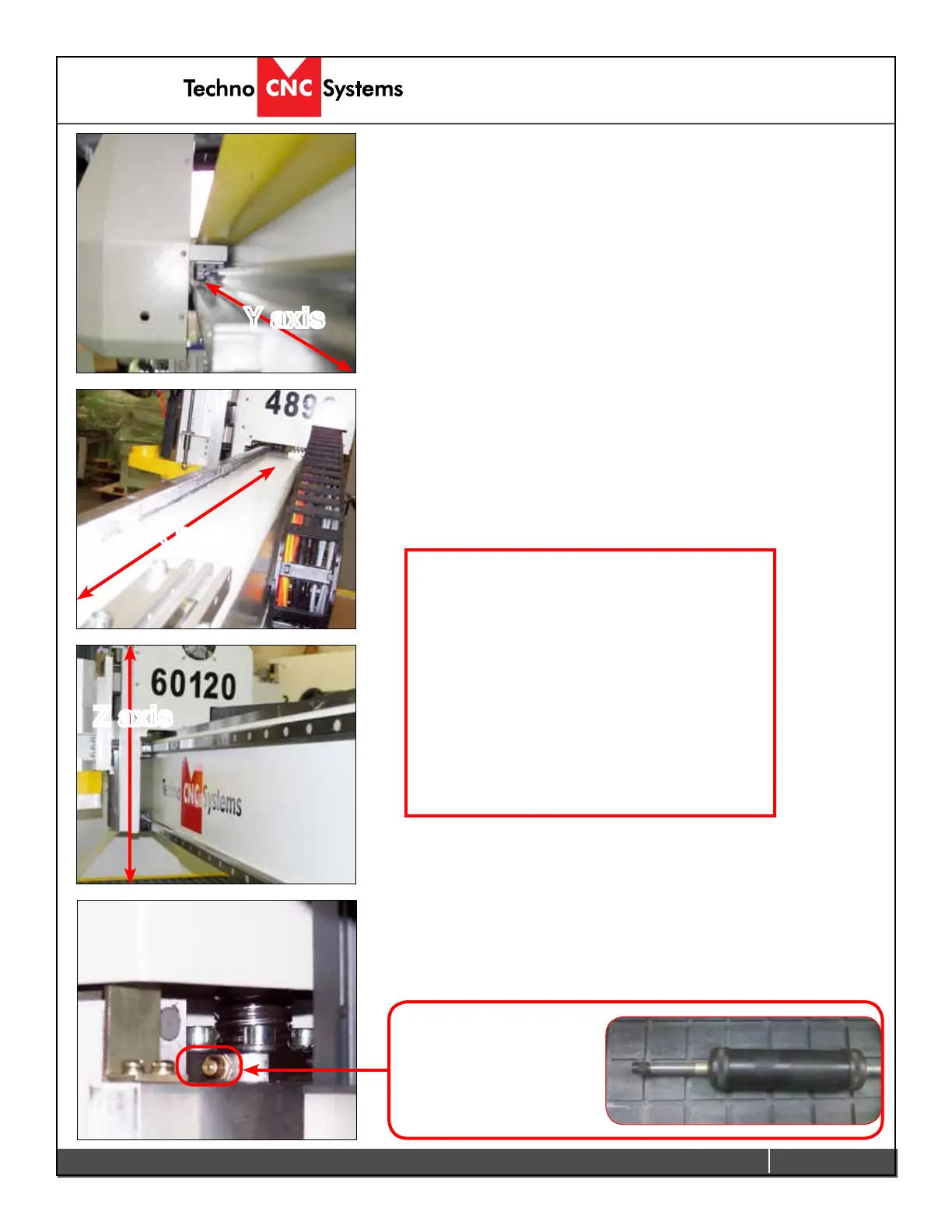

5.3 Lubricating Z Ballscrew

The Z axis uses a ballscrew and ballnut instead of a rack and pinion.

The ballnut has a nipple for applying lubrication to the mechanism.

Lithium grease is pumped

into the lubrication point with

the application gun provided

with the machine.

Recommended Lubricants.

Lithium Based Grease:

• AlvaniaGreaseNo.2(Shell)orEquivalent.

• Techno Part No. H90Z00-8670T8

Oil:

• Vactra No. 2s(mobile)

• TonnerOilorEquivalent.

• Techno Part No. H90200-LUBE002

Oil and Grease Kit:

• Techno Part No. H90Z00-LUBEKIT2

NOTE: AVOID A BUILD UP OF DEBRIS ON MOVING PARTS.

CLEAN OFF ANY DEBRIS TO AVOID DAMAGING THE MACHINE.

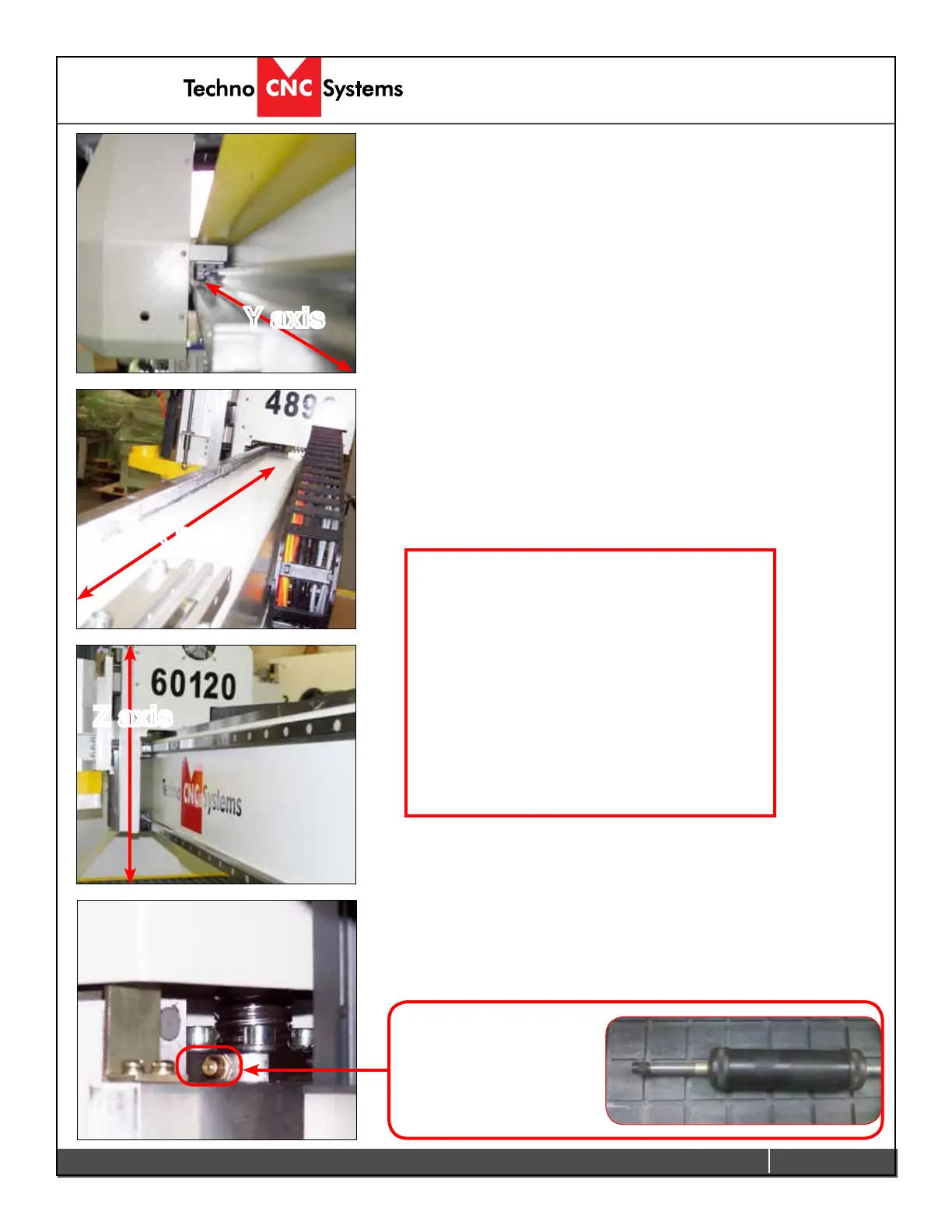

5.1 Lubricating the X-Y Rack and Pinion.

Lubrication is important with rack and pinion gearing systems. A thin

lmofgreaseshouldalwaysbepresentonthecontactingtoothanks

to minimize metal to metal contact. Lithium grease lubrication is

recommendedoveroil,astheoillubricationwillowawayfromtooth

anks.Theracksshouldbecleanedwithadegreasingagentand

fresh clean grease should be applied at regular intervals depending

on the usage of the machine. It is recommended that this is done

every 80 hours of machine usage. Use a small brush to coat both

racks on the side of the Y axis and the single rack across the X axis.

5.2 Lubricating the X-Y-Z Rails

The rail carriage bearings are sealed and protected with wipers.

The rails should be lightly oiled to allow smooth operation. Avoid a

build up of debris on the rails by blowing them off with air or wiping

them down with a rag. The rails do not need to be lubricated as

oftenastherack.Onceamonthshouldbesufcient.

Z axis

X axis

Y axis

Loading...

Loading...