6.Maintenance

6.1Daily Maintenance

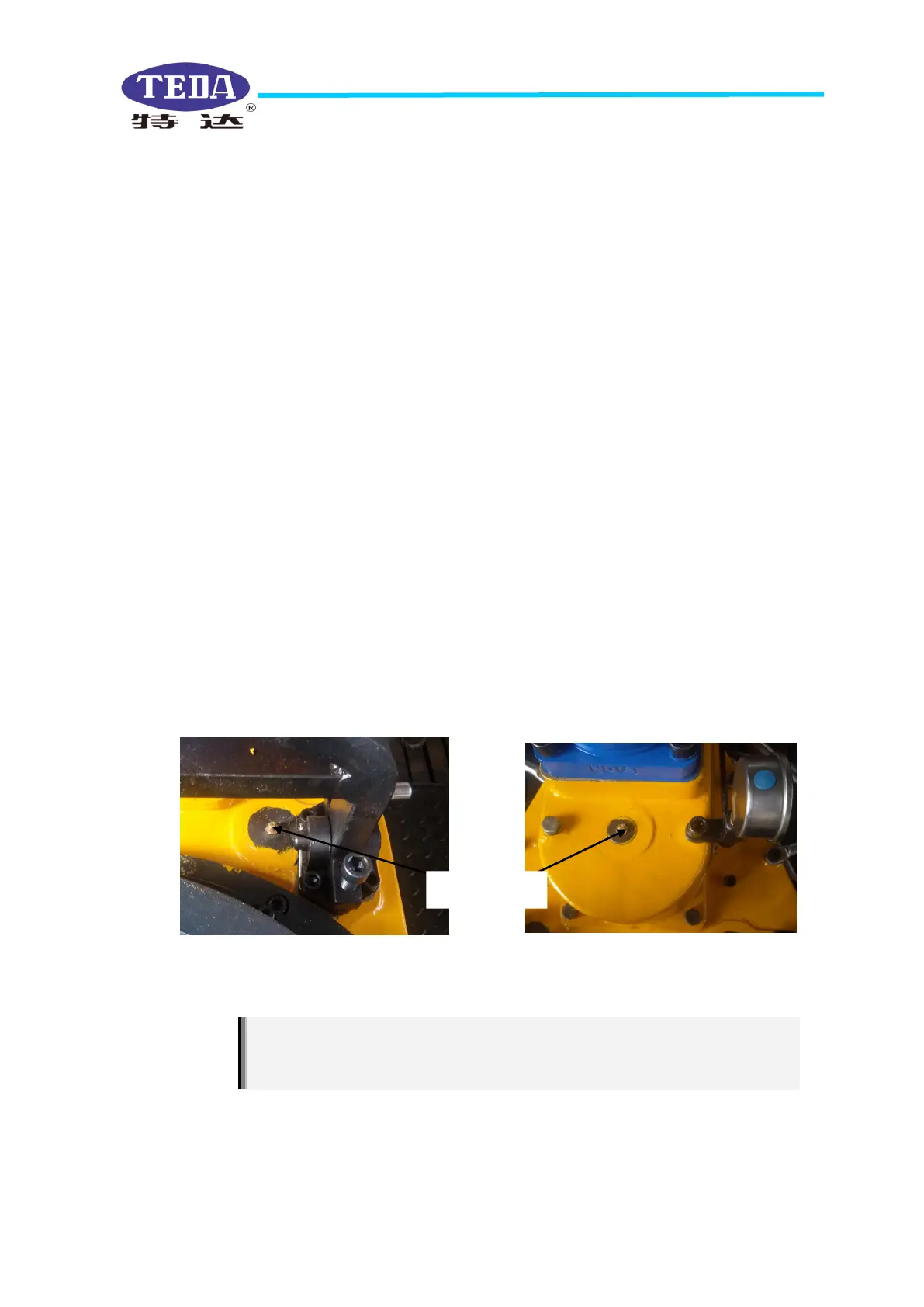

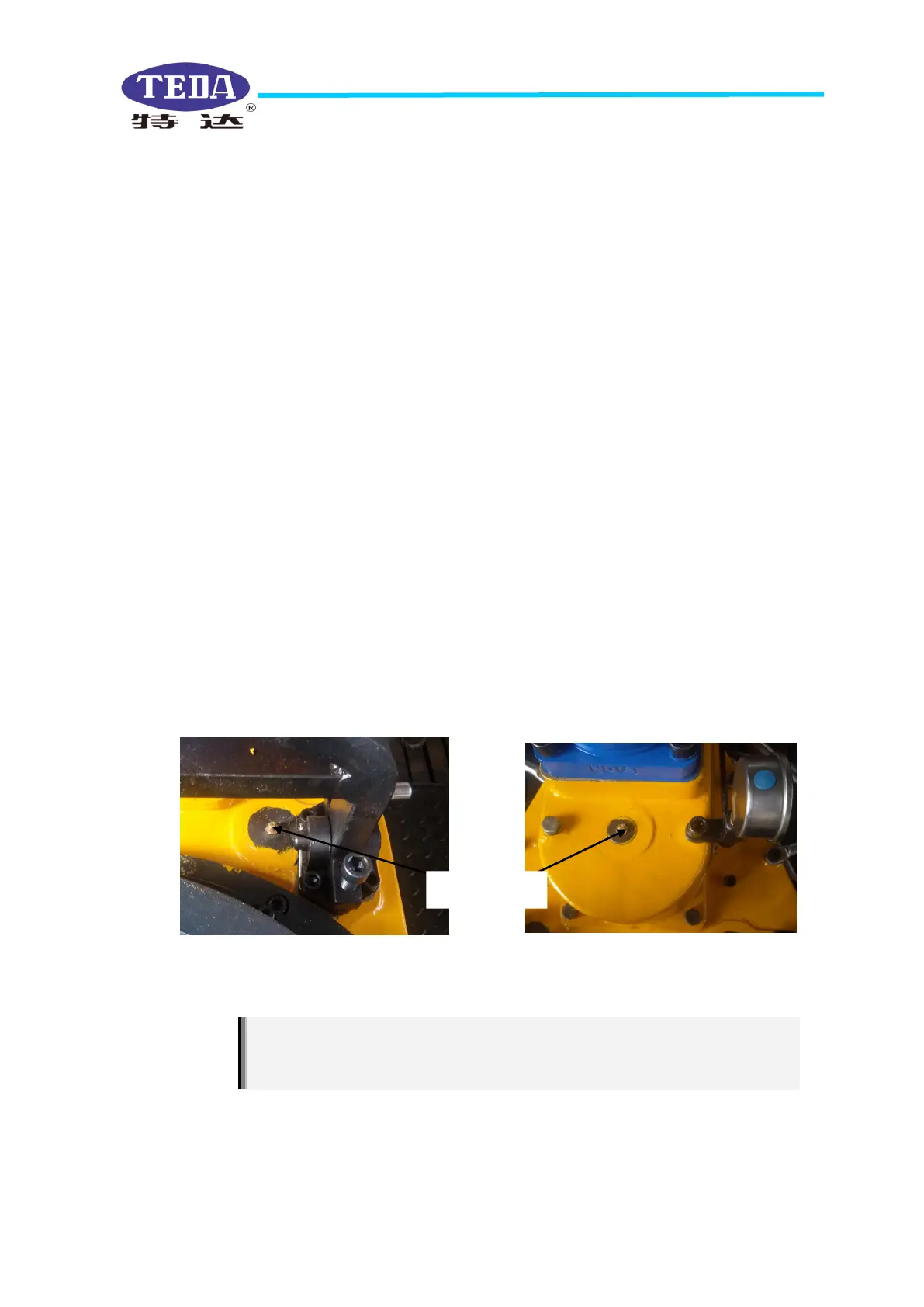

□Fill 25ml of lubricating grease to each grease nipple of the master axle, idle

gear-axle, and duplex gear axle. (Grease nipple positions are shown in Fig.6-1 and

Fig .6-2)

□Fill 25ml of engine oil to each of the following points: transmission pin, friction

disc, centralizing roller and jaw plate roller.

□Clean sundries from dies by wire brush.

□Clean up water and oil stain inside the tong.

□Check all parts (including jaw plate, die seat, dies and ramp plate), change or

repair if they are over-worn, damaged, rusted or leaking.

6.2 Monthly Maintenance

□Clean the hydraulic bucket and the tong head of master tong and backup tong by

kerosene or diesel oil after one month or one well operation is finished. (Including ramp

plate, roller, jaw plate, jaw plate frame, open gear), then cover one layer of grease.

□Dismount power tong, clean up oil stain, sand and clay, change over-worn or

damaged parts, fill lubricating grease or lubricating oil to each sliding and rotating

surface, and finally mount it carefully.

● Don’t clean bearing or oil nipple by steam, otherwise, parts like

bearing may get rusted and damaged.

● Don’t clean pressure sensor by steam, otherwise it may be damaged

Loading...

Loading...