MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

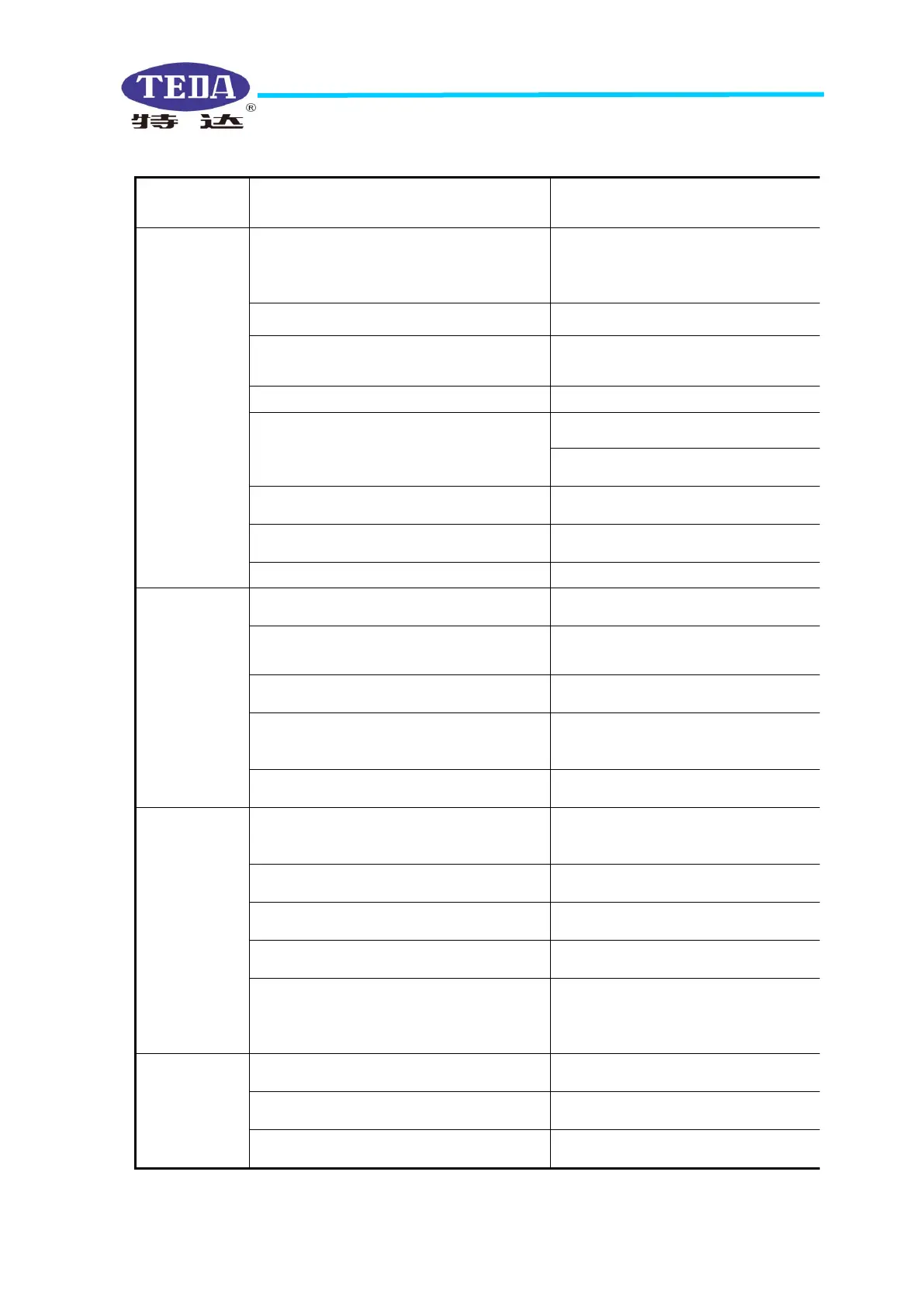

7.Common Troubles and Troubles Shooting Guide

Master tong

slips or dies

don’t

stretch out.

1 Die excessive wear,die unsuitable

or die groove full of hard things

Change die as table 3 and table 4

or clean hard things in die

groove.

2 Tong head braking torque

Tighten or change brake spring.

3 Jaw plate roller or roller shaft

damaged or get stuck.

Clean up parts or replace.

4 Ramp plate worn out or damaged.

1 Set the master tong level

2Adjustment , to make backup

tong and mater tong levels

6 Front and rear guide pole guide

spring blind or novelistic.

7 Die seat choose unsuitable.

Change die seat refer to gauge (or

change in pairs)

8 Pipe string hardness≥340HB

Backup tong

slips or dies

don’t

stretch out.

1Wrong connection of hose between

master and backup tongs.

2 Oil passage of master and backup

tong blocked.

Clean oil channel and filler core.

3 Rack plunger gets stuck

Shoot as the above-mentioned

methods.

4 The connection point between

cylinder body of tong tail and the tail

seat of the backup tong damaged.

Change tail cylinder, use same

specification die seat

5 Above eight slipped causes

According to the aforementioned

method。

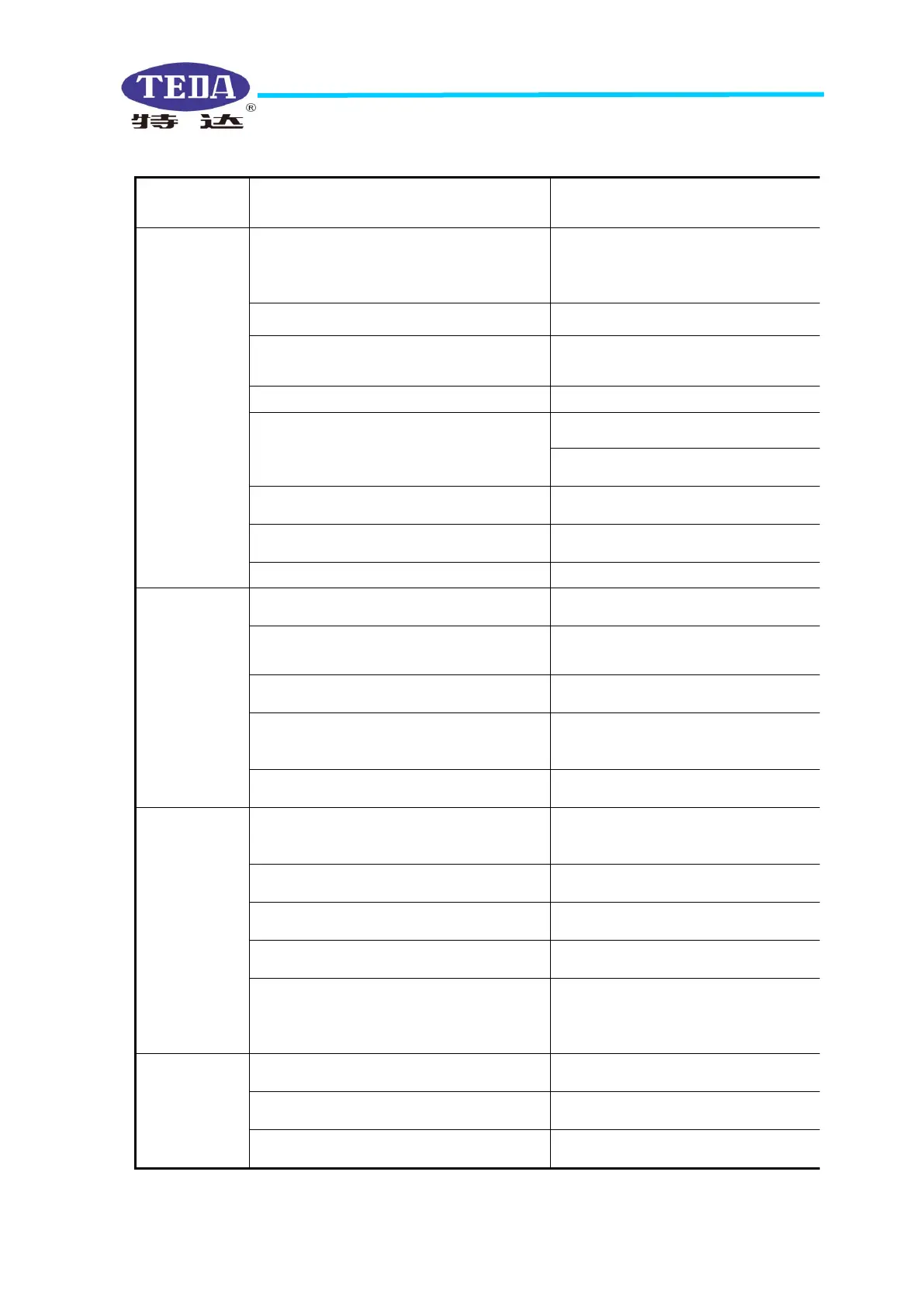

Backup tong

slips or dies

don’t

stretch out.

1 Roller moves out of the intended

distance.

Never make up or break out at

over torque; choose proper die

seats.

2 Damage of jaw plate, roller axle,

ramp or jaw plate frame,etc.

Repair, grind or replace proper

parts, don

’

t work at over torque.

3 Braking torque from tong head too

small

See the above-mentioned

method.

4 The jaw plate roller gets stuck.

Clean, grind or replace roller and

roller axle.

5 Die seats or dies of different

specifications are used on the two

sides of the master tong or backup

tong.

Choose the right dies or die

seats.

Master tong

and backup

tong

opening are

not aligning.

1 Wrong reverse shaft direction

180

º

twist reverse shaft, then

restoration.

2 Jaw plate is deformation or

damaged

Grinding the damage area or

replace.

Change reverse shaft , not

working exceed torque

Loading...

Loading...