MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

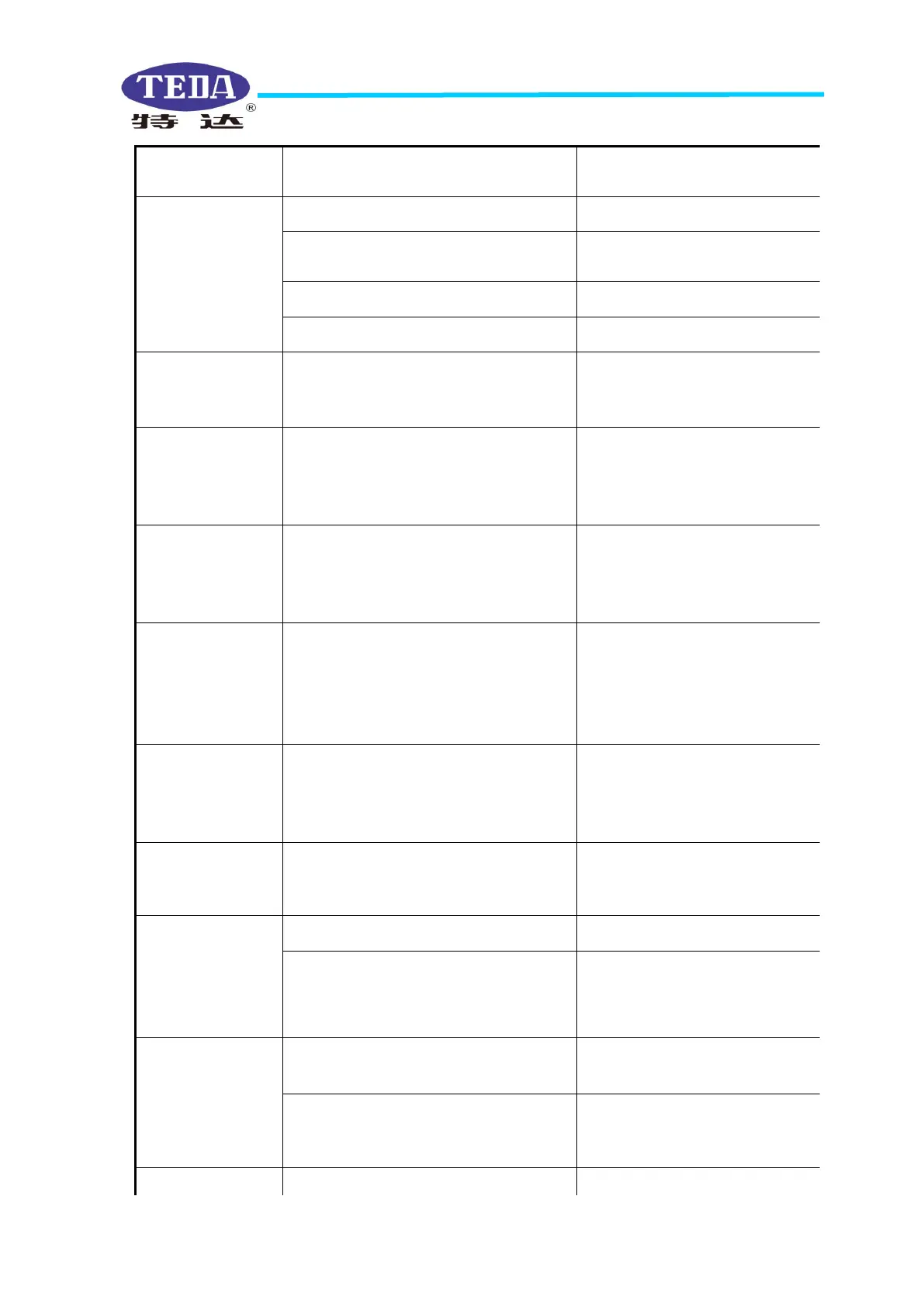

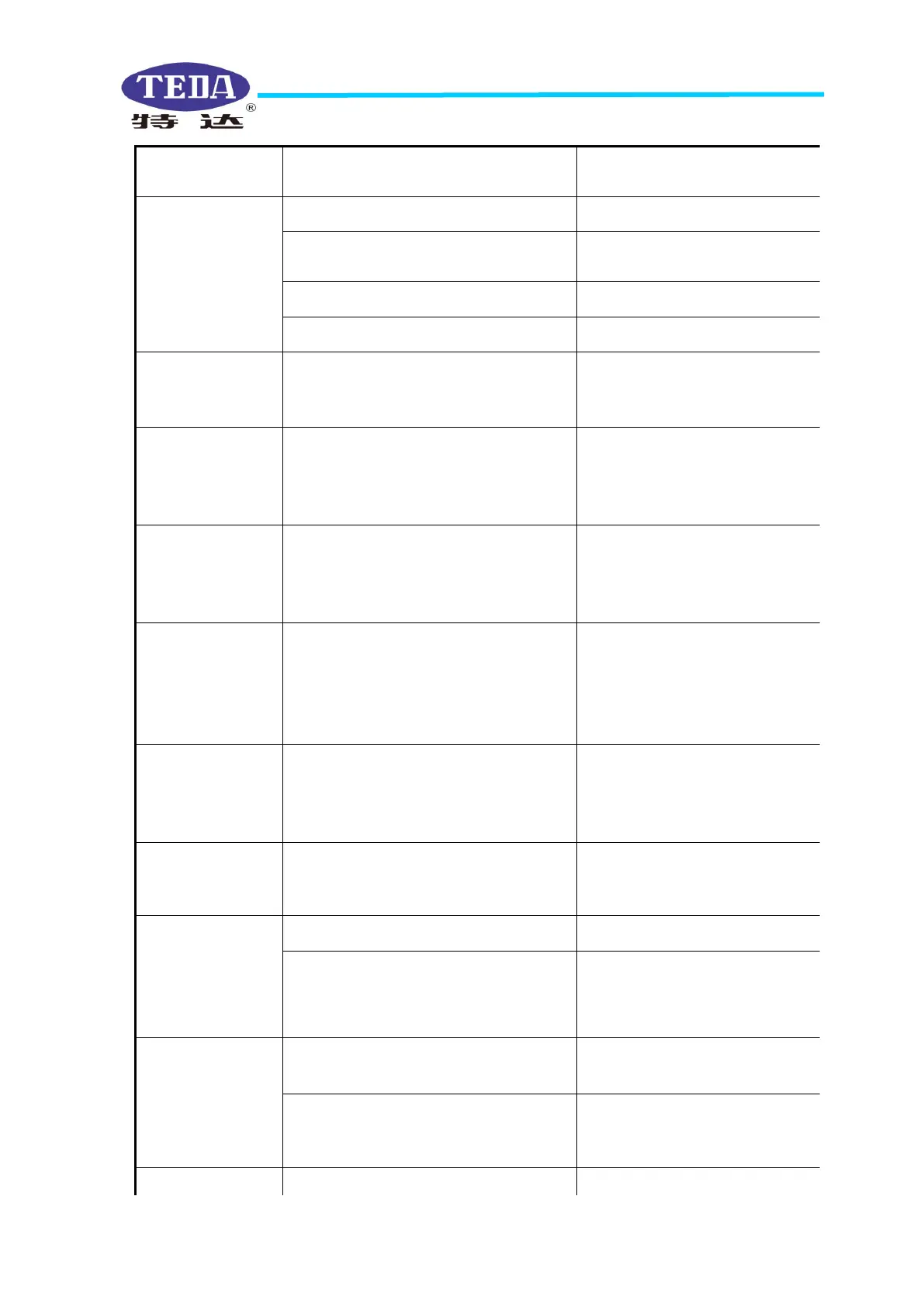

Low rotating

speed, but oil

outlet is normal.

1 Low discharge of hydraulic pump.

Adjust oil supply to 120L/min.

2 Viscidity of hydraulic oil too high

or too low.

Replace oil or heat up (esp. in

winter)

4 Hand control valve can’t slide

Low rotating

speed, high

pressure of oil

outlet.

Check valve of quick coupling can’t

be completely turned on or pipe

blocked.

Replace quick coupling or

clean the pipe.

Rotation of tong

head sometimes

slow, sometimes

fast.

Not enough oil sucked by the

hydraulic pump, air gets into the oil

passage.

Clean the filter core or make

up the amount of the

hydraulic oil.

The motor

rotates, while

the tong head

doesn

’

t rotate.

The transmission axle or gear

damaged.

Gears on both

sides of the

opening gear are

easily stripped

off

Upper and lower centralizers are

severely worn.

Replace centralizers in time.

Backup tong

clamps only in

one direction.

Rack plunger not in the central

position when jaw plate frame and

the opening of backup tong main

body are in alignment.

Dismount backup tong and

reassemble.

Making up or

breaking out too

sensitive.

The valve tail nut of hand control

valve gets loose.

Gear

engagement not

fast,

disengagement

occurs easily.

1.Not pushed to the right position.

2.Pressure on the positioning seat

from spring not enough.

1 Low system pressure.(such as

overflow valve not properly

adjusted or damaged)

2.Pressure of pressure adjusting

valve of the head control valve is

adjusted too low.

Adjust at 12Mpa by special

technicians.

Oil leakage from

the sealing parts

1.Lake of oil in the sensor cylinder.

Add oil to the senor cylinder.

Replace the torque meter.

1 Torque gauge is damaged

In case troubles still can’t be solved, please contact our service staff.

Loading...

Loading...