8. Install a Ground Fault Circuit

Interrupter (GFCI) in circuit; it will

sense a short-circuit to ground and

disconnect power before it becomes

dangerous to pool users. For size of

GFCI required and test procedures for

GFCI, see manufacturer’s instructions.

In case of power outage, check GFCI

for tripping (which will prevent

normal pump operation). Reset if

necessary.

9. Connect current carrying conductors

to terminals L1 and L2 under motor

canopy. When replacing motor,

check wiring diagram on motor

nameplate against Figure 2. If the

motor wiring diagram does not

match either diagram in Figure 2,

follow the diagram on the motor.

IMPORTANT: 115/230 Volt single

phase models are shipped from factory

with motor wired for 230 volts. If

power supply is 115 volts, remove

motor canopy and reconnect motor as

shown in Figure 2. Do not try to run

motor as received on 115 volt current.

10.Motor has automatic internal

thermal overload protection. If

motor has stopped for unknown

reasons, thermal overload may

restart it unexpectedly, which could

cause injury or property damage.

Disconnect power before servicing

motor.

11.If this procedure or the wiring

diagrams are confusing, consult a

licensed electrician.

Operation

Hazardous suction.

Can trap hair or

body parts, causing severe injury

or death. Do not block suction. Small

children using pool must ALWAYS have

close adult supervision.

Explosion and

steam burn hazard.

Do not operate pump with discharge

valve closed. Trapped water can turn to

steam and cause pump to explode.

NOTE: NEVER run pump dry. Running

pump dry may damage seals, causing

leakage and flooding. Fill pump with

water before starting motor.

Before removing trap cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and

discharge pipes.

3. RELEASE ALL PRESSURE from pump

and piping system.

If pump is being pressure tested,

be sure pressure has been released

before removing trap cover.

Fire and burn

hazard. Modern

motors run at high temperatures. To

reduce the risk of fire, do not allow

leaves, debris, or foreign matter to

collect around the pump motor. To

avoid burns when handling the motor,

let it cool for 20 minutes before trying

to work on it. An automatic internal

cutoff switch protects the motor from

heat damage during operation.

PRIMING PUMP

Release all pressure from filter, pump,

and piping system; see the filter

owner’s manual.

In a flooded suction system (water

source higher than pump), pump will

prime itself when suction and

discharge valves are opened.

If pump is not in a flooded suction

system, remove trap lid; fill trap and

pump with water.

NOTE: Lubricate trap cover O-Ring

with petroleum jelly each time it

is removed.

Clean and inspect O-Ring; reinstall on

trap cover.

Replace trap cover on trap; tighten

T-bolt handles.

Pump should prime now. Priming time

will depend on vertical length of

suction lift and horizontal length of

suction piping.

If pump does not prime, make sure

that all valves are open, suction pipe

end is under water, pump is not trying

to lift water more than 10', and that

there are no leaks in suction pipe.

See Troubleshooting Guide.

Models 4RH36, 4RH37, 4RH38, 4RH39, and 4RH40

5

Teel Operating Instructions and Parts Manual

E

N

G

L

I

S

H

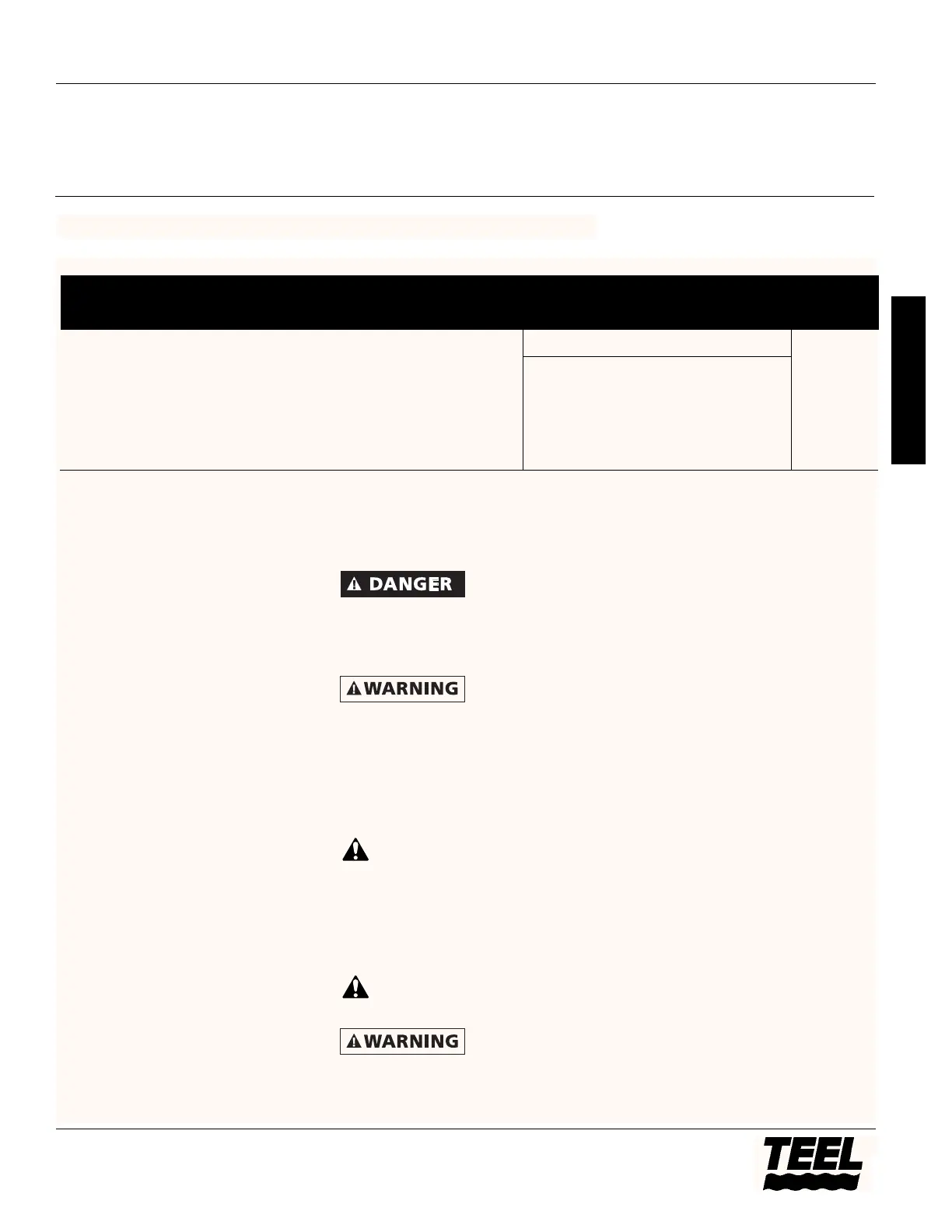

AWG WIRE SIZE

3/4 115/230 12.4/6.2 20/15 12/14 10/14 8/14 75

1 115/230 15.4/7.7 20/15 12/14 8/14 6/14 75

1

1

⁄2 115/230 18.2/9.1 30/15 10/14 8/14 6/12 75

2 230 10.4 15 14 14 12 75

2

1

⁄2 230 11.2 15 14 14 12 75

Branch Distance in Feet - Motor to Service

Full Load Circuit Breaker Temp

HP Volts Amps Amp Rating 0 - 100 101 - 200 201 - 300 Rating °C

Table I - Recommended Fusing and Wiring Data 60 Hz Motors

Installation (Continued)

®

Loading...

Loading...