29

All Tekno RC vehicles are built out of the box with a neutral setup but are highly tunable to your individual driving

needs. Before you start changing your setup on the car itself, it’s best to ensure you’re getting the best setup out

of your radio. It’s easy to forget that a lot of simple tuning can be done right from your controller. To help with this,

we recommend that you are well informed about setting up your Steering End Points (EPA), Dual Rate (D/R),

Exponential Curves, and Servo Speed.

Start by setting your steering EPA such that the vehicle can reach ‘full lock’ while on the ground. Be careful not to

go too far with this setting as it may damage your servo. Drive the vehicle around the track. If you are turning into

pipes or losing traction out of a corner, you probably have too much overall steering throw. The simplest way to

reduce this is with Dual Rate. Reducing Dual Rate will turn down both the left and right side EPA proportionately

without having to adjust the EPA settings independently. D/R is usually pre-assigned to one of the trim buttons

on most mid-to-high level radios.

The next setting is ‘Expo’ or ‘Curve’. Expo does not change your EPA or D/R, it simply turns the wheels less around

center and ramps up to the end points as you reach full lock on the steering wheel. We would suggest starting at

-10%. If your vehicle still feels “twitchy” around center, dial in more negative expo to continue smoothing every-

thing out. If it starts to feel too numb around center, dial some out.

Another valuable and often overlooked radio adjustment is “Servo Speed”. Servo Speed allows you to slow the

steering servo down from the transmitter resulting in reduced twitchiness. We like to set this at around -10 to

start. If you find that it’s too lazy, increase the servo speed slightly and run a few more laps. Repeat as necessary

until the steering response feels natural without delay.

After setting the servo speed you might find that you need to go back and adjust the expo setting. This is normal,

it might take a few adjustments of each to achieve the proper steering “feel” to suit your driving style and track

conditions.

The last setting to look at would be your brake end point or brake dual rate. Having brakes set correctly can gain

you tenths on the track and improve your consistency. Set your brake dual rate to 80% and then set your end-

point so that the brakes are just strong enough to not allow

you to push your car forward on the bench during full

braking. Once on the track, this might be too strong or too weak of a setting depending on the available traction.

Start turning the brake dual rate up or down a few percentage points at a time until you achieve your desired “feel”.

Under maximum braking you’ll want your tires to be as close as possible to locking up without them actually doing

it. Keep in mind that this setting will change from track to track and even throughout the day as track conditions

can vary. Don’t forget that you can also use servo speed for your throttle and brake in the same way you did for

the steering.

With these five settings, you should be able to make your vehicle more consistent and easier to drive, lap

after lap, assuming the rest of the vehicle setup is close for your particular track. Of course there are many

other factors and setup options to tune on your vehicle, but sometimes all you need is a small radio adjust-

ment to keep you headed in the right direction.

Radio Adjustments and Information

Pistons with smaller holes work well for

smoother tracks with large jumps and pistons

with larger holes work well for rougher tracks

with less jumps. Smaller hole pistons will

typically use thinner oil than larger hole

ambient temperature so a change in viscosity might be

necessary with a change of 5°C or ~10°F.

Pistons

Sway bars are used to adjust a

vehicle's lateral grip by resisting

chassis roll. A thicker bar

decreases roll more than a

thinner bar will. More roll means

more grip and less roll means less grip. The front sway bar

stability in mid-corner and at corner exit.

Sway Bars

Softer springs will increase traction through the turns by

allowing more roll, slow down the responsiveness of the

will increase corner speed if traction is available and will

also tend to jump and land better. Once you find a set of

springs you like you will typically only change them for

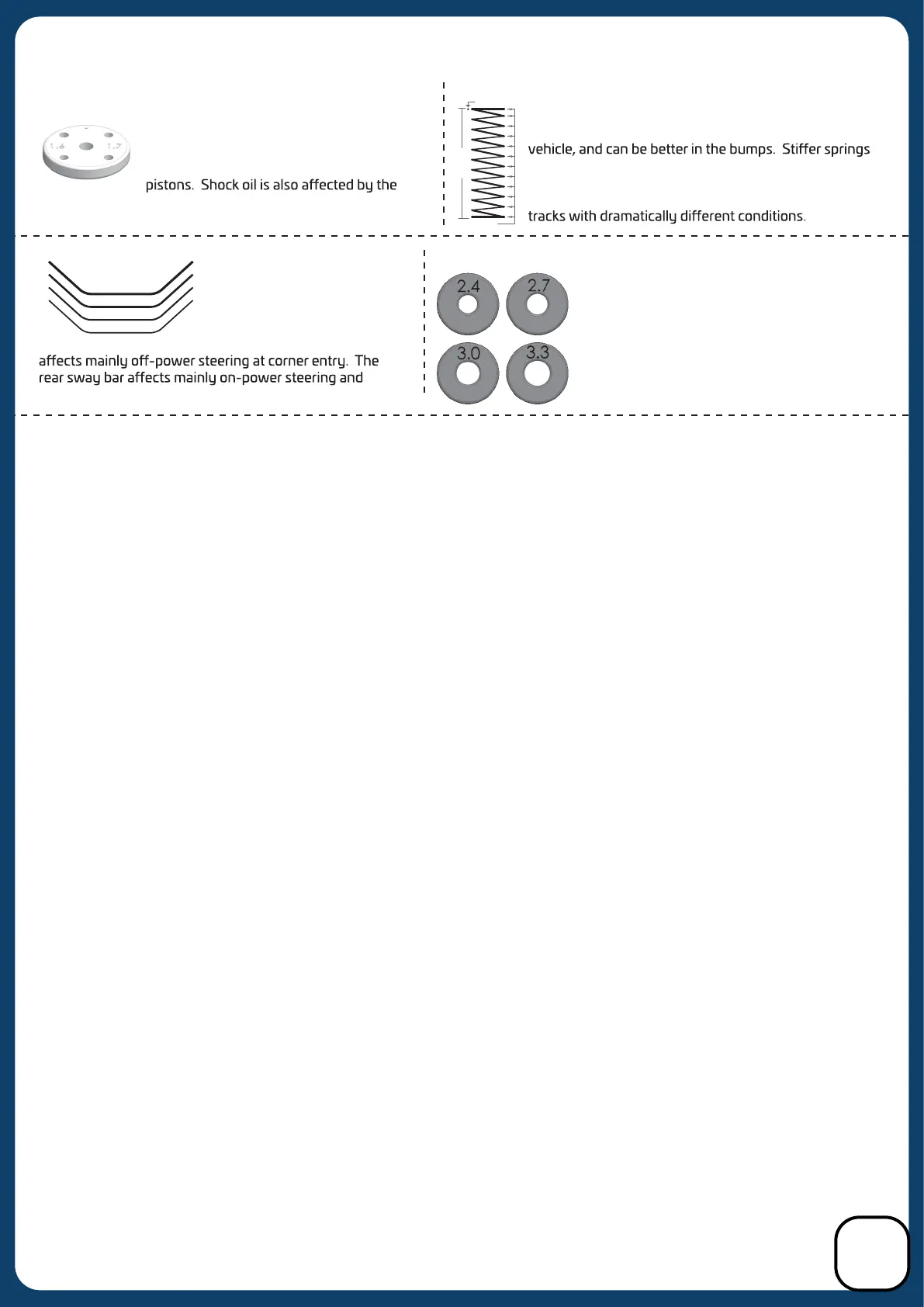

Springs

LENGTH

COILS

WIRE DIA.

Setup Information

(continued)

Sway Bar Deadband Bushings

Sway bar deadband bushings allow you to

accurately set the amount of deadband your sway

bars have. In general, more deadband (larger

diameter bushings) work better on rough tracks

and less deadband (smaller diameter bushings)

work better on smooth tracks. Typically you’ll

want the bushing diameter to be ~0.3mm -

0.6mm larger than the swaybar’s diameter.

Loading...

Loading...