WARNING:

WARNING:

WARNING:

BEFORE PROCEEDING WITH REPAIRS TO

THE MACHINE READ THE INSTRUCTION

MANUAL CAREFULLY.

EXTRAORDINARY MAINTENANCE SHOULD

BE CARRIED OUT ONLY AND EXCLUSIVELY

BY EXPERT OR SKILLED ELECTRICAL-

MECHANICALPERSONNEL.

ANY CHECKS CARRIED OUT INSIDE THE

MACHINEWHEN IT IS POWERED MAY CAUSE

SERIOUS ELECTRIC SHOCK DUETO DIRECT

CONTACTWITHLIVEPARTS.

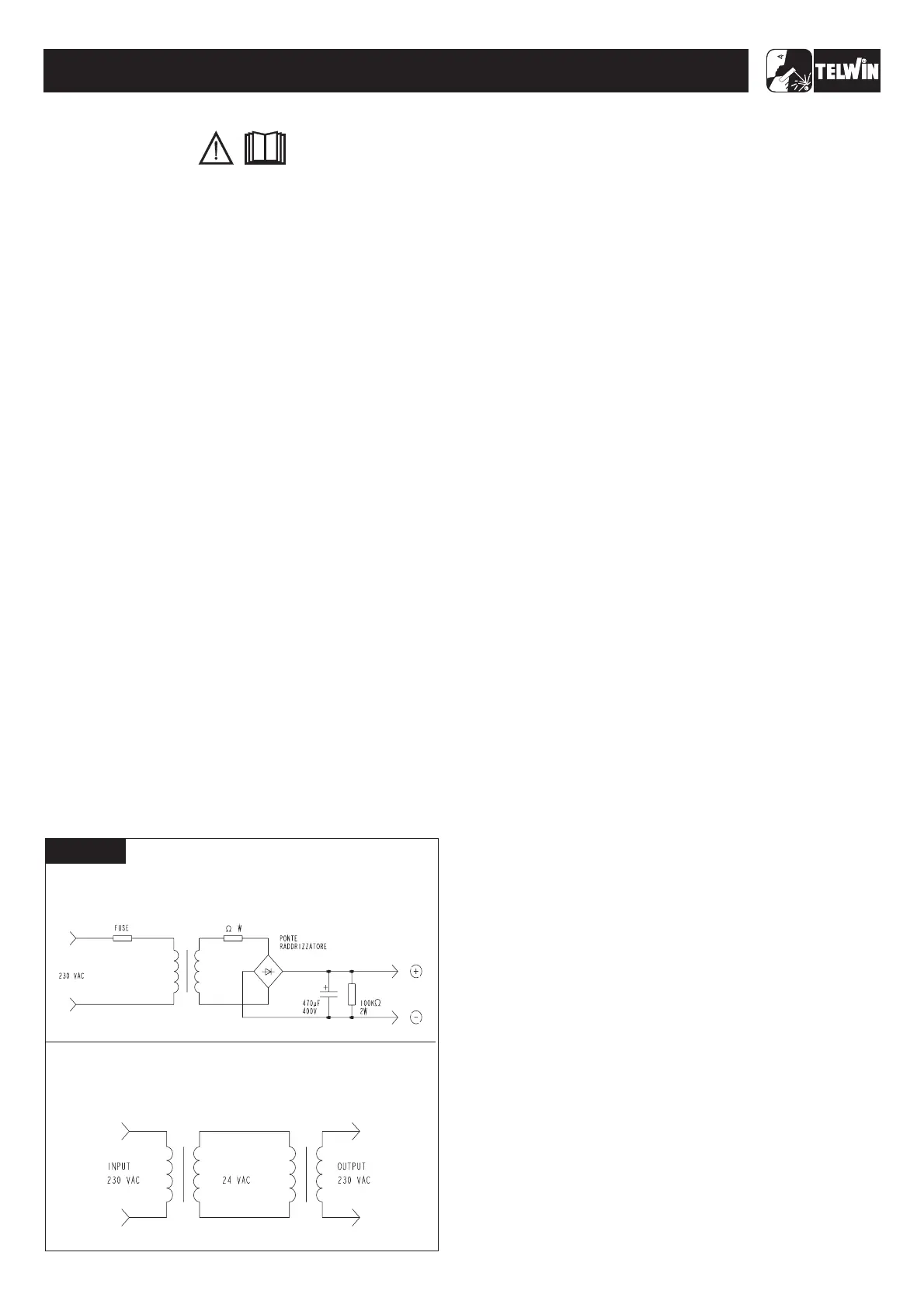

HV POWER SUPPLY MODULE

THE HV POWER SUPPLY is used to ensure operation of the

switching power supply (the circuit on the primary board supplying

auxiliary voltages), even when the machine is operating at low

voltage.

It is easy to build using the electrical diagrams in fig. A for

reference and using the following components or, alternatively, it

canbeorderedfromTelwin.

T1=insulationtransformer230-230V 50VA(*)

D1=rectifierbridge36MB80 (cod.112357)

C1= electrolytic capacitor470uF 400V ALL

(cod.112514)

R1= resistor 10ohm 5W 5%

R2= resistor 100Kohm 2W 5%

F1= delayedaction fuse 1.5 A Fuseholder 5X20mm

Female redand blackfaston

Plasticbox.

The following is a list of practical rules which must be strictly

adheredto if repairsare to be carried out correctly.

A) When handling the active electronic components, the IGBT's

and Power DIODES in particular, take elementary antistatic

precautions (use antistatic footwear or wrist straps, antistatic

working surfacesetc.).

B) To ensure the heat flow between the electronic components

and the dissipator, place a thin layer of thermo-conductive

grease (e.g. COMPOUND GREASIL MS12) between the

contactzones.

C) The power resistors (should they require replacement) should

alwaysbe soldered atleast 3 mmabovetheboard.

D) If silicone is removedfrom some points on the boards,it should

be re-applied. Use only non-conducting neutral or oximic

reticulating silicones (e.g. DOW CORNING 7093). Otherwise,

silicone that is placed in contact with points at different

potential (rheophores of IGBT's, etc.) should be left to

reticulatebeforethe machineis tested.

E) When the semiconductor devices are soldered the maximum

temperature limits should be respected (normally 300 Cfor no

morethan 10 seconds).

F) It is essential to take the greatest care at each disassembly

andassemblystage forthevarious machine parts.

G) Take care to keep the small parts and other pieces that are

dismantled from the machine so as to be able to position them

in the reverse order when re-assembling (damaged parts

should never be omitted but should be replaced, referring to

thespare parts list givenat the end of this manual).

H) The boards (repaired when necessary) and the wiring should

neverbe modifiedwithout prior authorisationfromTelwin.

I) For further information on machine specifications and

operation,refertothe InstructionManual.

J) When the machine is in operation there are

dangerously high voltages on its internal parts so do not touch

theboards when themachine is live.

Every operation should be carried out in complete

safety with the power supply cable disconnected from the mains

outlet:

- Undo the 8 screws fastening the 2 plastic covers (4 each) to the

frontand back .

- Undo the 8 screws fastening the top cover to the structure

.

- Slide out the topcoverbypullinggently outwards .

After completing the repairs, proceed in the reverse order to re-

assemble the cover and do not forget to insert the toothed washer

onthe groundscrew.

Using suitably dried compressed air, carefully clean the

components of the power source since dirt is a danger to parts

subject to high voltages and can damage the galvanic separation

betweenthe primary andsecondary.

To clean the electronic boards we advise decreasing the air

pressureto preventdamage to thecomponents.

It is therefore important to take special care when cleaning the

followingparts

Check whether dirt has been deposited on the front and back air

vents or has damaged the correct rotation of the blades, if there is

stilldamage after cleaningreplace the fan.

rheofores ofIGBT's Q1, Q2,Q3, Q4;

rheofores ofrecirculating diodes D4, D8;

rheofores ofsnubbernetworkdiodes D1, D6;

GENERAL REPAIR INSTRUCTIONS

TROUBLESHOOTING AND REMEDIES

N.B.

WARNING!

WARNING!

(figure1A)

(figure1B)

(figure1B)

-

-

-

°

1.0 Disassembling the machine

2.0 Cleaning the inside of the machine

Fan fig. 2B

Primary board (fig. 3:)

()

-11-

10 5

F1

R1

R2

D1

T1

FIGURE A

TECHNOLOGY 150-170-200-186CE/GE

TECHNOLOGY 150-170-200-186CE/GE

ELECTRICAL DIAGRAM FOR POWER SUPPLY (HV OUTPUT):

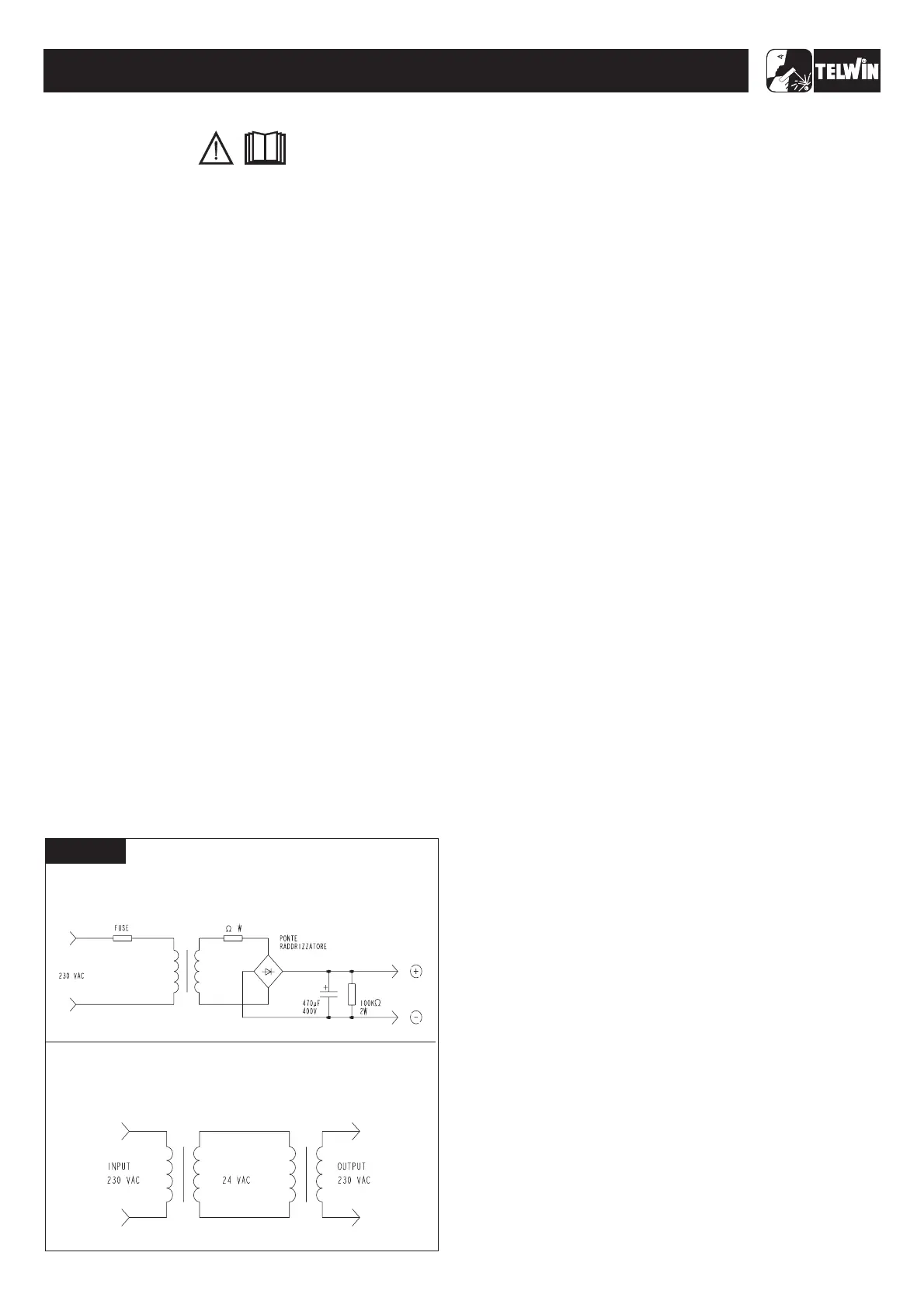

THE INSULATION TRANSFORMER CAN BE REPLACED WITH

TWO TRANSFORMERS OF THE SAME POWER,

CONNECTING THE SECONDARIES ACCORDING TO THE

FOLLOWINGDIAGRAM:

Loading...

Loading...