- 3 -

glass (do not pour the product directly onto the lter).

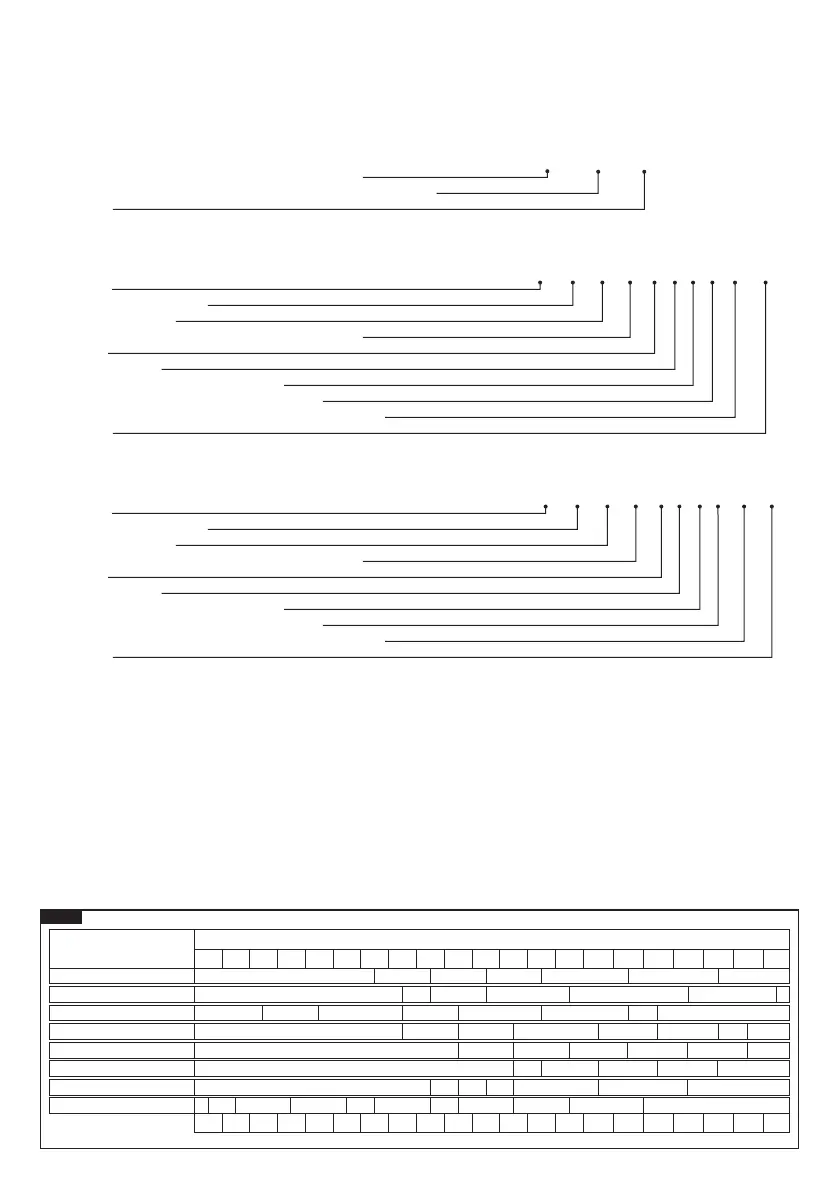

ASSEMBLY

Assemble as shown in the drawing (Fig. A).

INFORMATION ON THE MARKING

The marking in the front section of the helmet model TW 6000 is made up of a series of symbols with the following meaning:

TW EN 175 CE

Symbol of the producing company: TELWIN – ITALY

Standard number that was referred to for requesting certication

CE marking

The marking given in the upper-front section of the model TW 060 lter is made up of a series of symbols with the following

meaning:

4/5 - 9/9 - 13 TW 1 / 2 / 1 / 2 379 CE

Light shade

Lightest dark scale number

Darkest scale number

Symbol of the producing company: TELWIN – ITALY

Optic class

Light diffusion class

Light transmission factor variation class

Light transmission factor angular dependence

Standard that was referred to for requesting certication

CE marking

The marking given in the upper-front section of the model TW 260 lter is made up of a series of symbols with the following

meaning:

4/5 - 9/9 - 13 TW 1 / 1 / 1 / 2 379 CE

Light shade

Lightest dark scale number

Darkest scale number

Symbol of the producing company: TELWIN – ITALY

Optic class

Light diffusion class

Light transmission factor variation class

Light transmission factor angular dependence

Standard that was referred to for requesting certication

CE marking

The certication procedure indicated in Art. 10 of the 89/686/EEC Directive was carried out by DIN CERTCO Gesellschaft

fuer Konformitaetsbewertung mbH, Alboinstrasse 56, 12103 Berlin, Notied body number 0196.

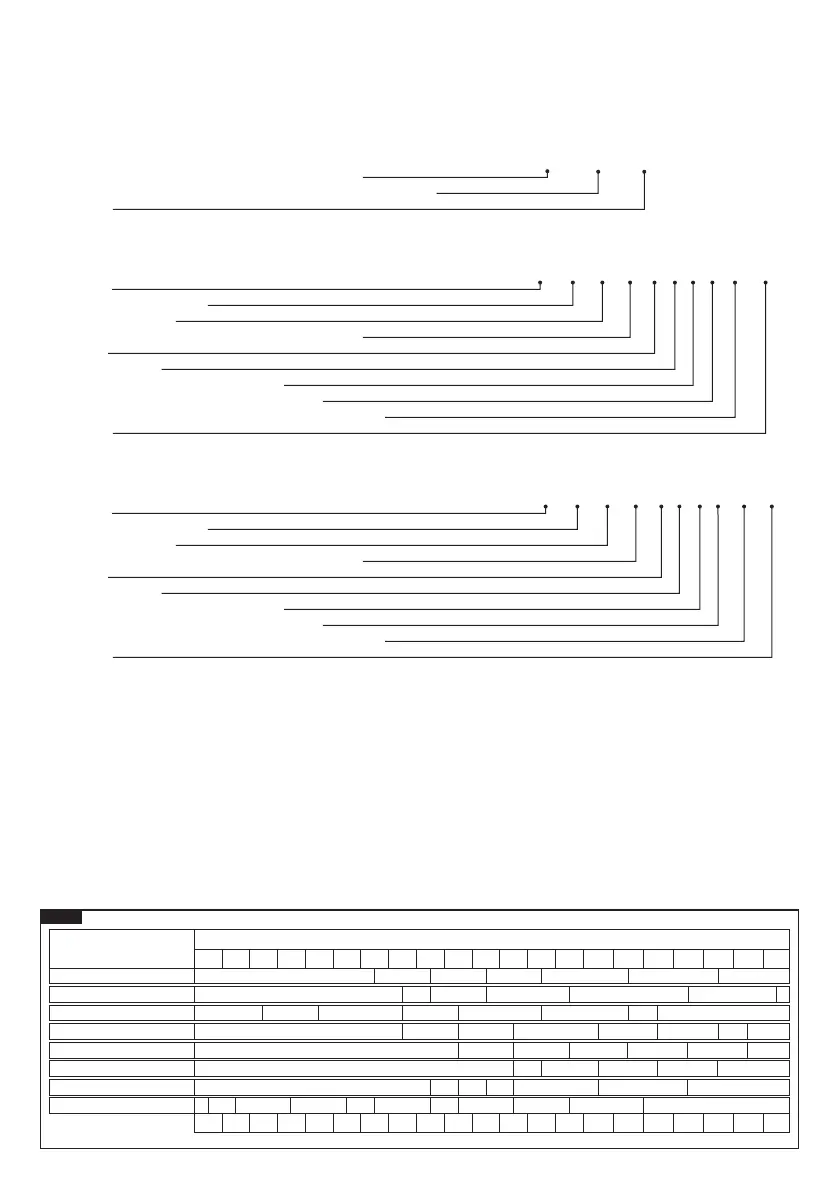

MAG

TIG

12

1.5

Welding process

and related technics

Coated electrodes

MIG on heavy metals (*)

MIG on light alloys

Air-arc cutting

Plasma-jet cutting

Microplasma arc welding

8

8

10

4 5 6 7 8 9 10 11

9 10 11 12 13

11 12 13 14 15

8

10 11 12 13 14

9 10 11 12 13 14

9 10 11 12 13

9 10 11 12 13 14

9 10 11 12 13 14

6

10 15 30 40 60 70 100 125 150 175 200 225 250 300 350 400 450 500 600

1.5 6 10 15 30 40 60 70 100 125 150 175 200 225 250 300 350 400 450 500 600

Amper Current

Numbers of shades and uses recommended for arc welding

(*) The term "Heavy metals" refers to steel and its alloys, copper and its alloys.

TAB. 1

Loading...

Loading...