F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

23

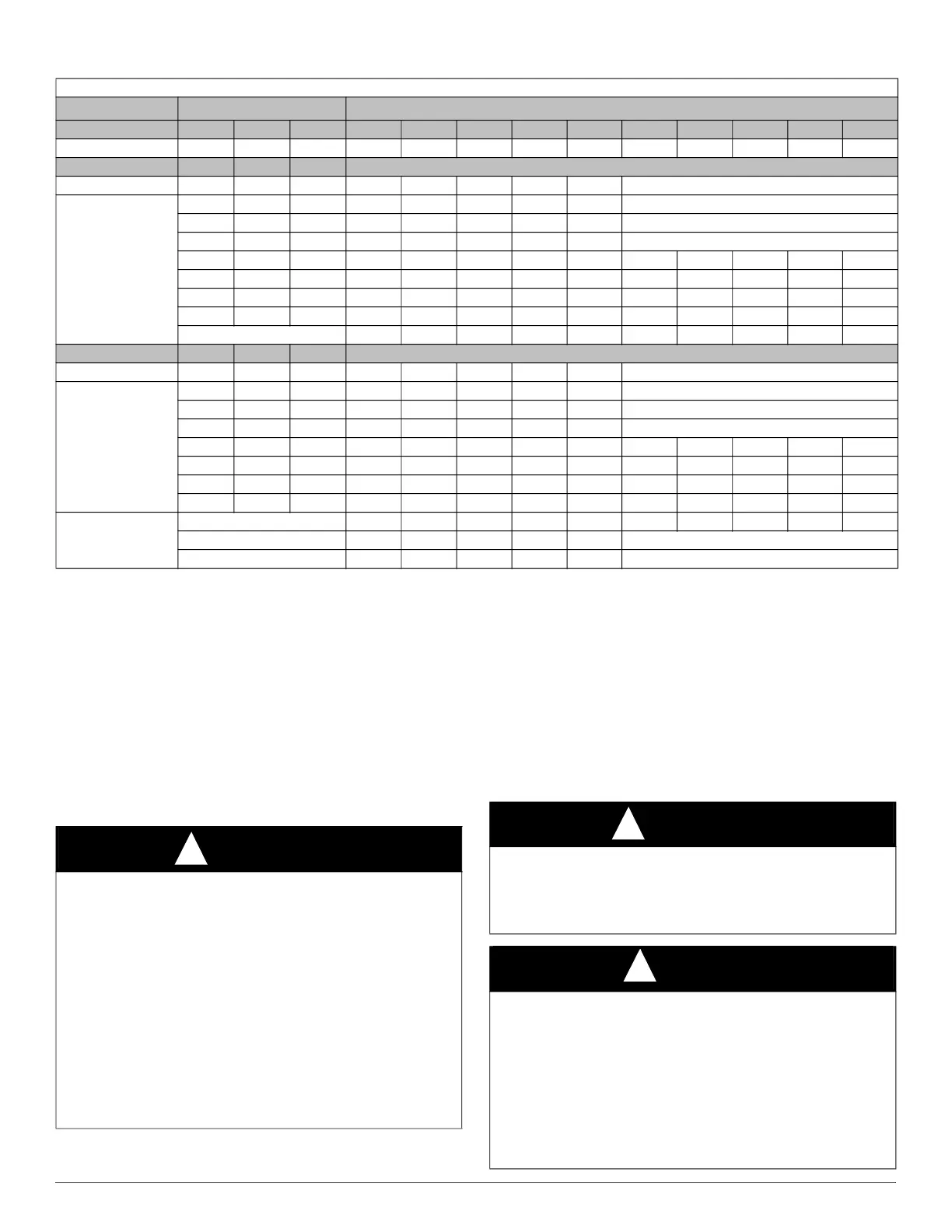

See Notes following table.

NOTES:

1.Nominal 350 CFM/ton cooling airflow is delivered with SW1-5 and SW4-3 set to OFF.

Set SW1-5 to ON for nominal 400 CFM/ton (+15% airflow).

Set SW4-3 to ON for nominal 325 CFM/ton (-7% airflow).

Set both SW1-5 and SW4-3 to ON for nominal 370 CFM/ton (+7% airflow).

This applies to Cooling and Low-Cooling airflow, but does not affect continuous fan airflow.

The above adjustments in airflow are subject to motor horsepower range/capacity.

2.Maximum cooling airflow is achieved when switches SW2-1, SW2-2, SW2-3 and SW1-5 are set to ON, and SW4-3 is set to OFF.

3.All heating CFM’s are when low/medium heat rise adjustment switch (SW1-3) and comfort/efficiency adjustment switch (SW1-4) are both set to OFF.

4.Ductwork must be sized for high-heating CFM within the operational range of ESP. Operation within the blank areas of the chart is not

recommended because high-heat operation will be above 1.0 ESP.

5.All airflow on 21” casing size furnaces are 5% less on side return only installations.

6.Return air above 1800 CFM on 24.5” casing sizes requires two sides, one side and bottom or bottom only, to allow sufficient airflow to the furnace.

GAS PIPING

(SW1-5 and SW4-3 set to OFF, except as indicated. See notes 1 and 2.)

Unit Size: 1202422 Clg/CF Switch settings External Static Pressure (ESP)

Clg Switches SW2-3 SW2-2 SW2-1 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Clg Default: OFF OFF OFF 1850 1855 1860 1855 1850 1830 1805 1775 1750 1730

CF Switches SW3-3 SW3-2 SW3-1

Low-Clg Default: OFF OFF OFF 930 925 915 900 885 See note 4

Cooling Airflow

(SW2)

Low-Cooling

Airflow (SW3)

OFF OFF ON 765 745 740 705 680 See note 4

OFF ON OFF 930 925 915 900 885 See note 4

OFF ON ON 1095 1100 1110 1105 1085 See note 4

ON OFF OFF 1265 1255 1265 1280 1275 1285 1270 1260 1250 1230

ON OFF ON 1465 1455 1470 1465 1465 1470 1455 1450 1435 1415

ON ON OFF 1850 1855 1860 1855 1850 1830 1805 1775 1750 1730

ON ON ON 2200 2200 2200 2190 2185 2170 2145 2085 1990 1890

Maximum Clg Airflow

2

2200 2200 2200 2190 2185 2170 2145 2085 1990 1890

CF Switches SW3-3 SW3-2 SW3-1

Cont. Fan Default: OFF OFF OFF 930 925 915 900 885 See note 4

Continuous Fan

Airflow (SW3)

OFF OFF ON 765 745 740 705 680 See note 4

OFF ON OFF 930 925 915 900 885 See note 4

OFF ON ON 1095 1100 1110 1105 1085 See note 4

ON OFF OFF 1265 1255 1265 1280 1275 1285 1270 1260 1250 1230

ON OFF ON 1465 1455 1470 1465 1465 1470 1455 1450 1435 1415

ON ON OFF 1465 1455 1470 1465 1465 1470 1455 1450 1435 1415

ON ON ON 1465 1455 1470 1465 1465 1470 1455 1450 1435 1415

Heating (SW1)

Maximum Heat Airflow

3

1815 1820 1825 1820 1815 1795 1775 1745 1720 1700

Intermediate Heat Airflow

3

1095 1100 1110 1105 1085 See note 4

Minimum Heat Airflow

3

905 900 890 875 855 See note 4

Table 7 – Cooling

4

and Heating Air Delivery - CFM (Bottom Return

5

With Filter) (Continued)

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Never purge a gas line into a combustion chamber. Never test for gas

leaks with an open flame. Use a commercially available soap solution

made specifically for the detection of leaks to check all connections. A

fire or explosion may result causing property damage, personal injury

or loss of life.

Use proper length of pipe to avoid stress on gas control manifold and

gas valve.

Gas valve inlet and/or inlet pipe must remain capped until gas supply

line is permanently installed to protect the valve from moisture and

debris. Also, install a sediment trap in the gas supply piping at the inlet

to the gas valve.

CAUTION

!

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in furnace damage.

Connect gas pipe to furnace using a backup wrench to avoid damaging

gas controls and burner misalignment.

NOTICE

!

In the State of Massachusetts:

1. Gas supply connections MUST be performed by a licensed

plumber or gas fitter.

2. When flexible connectors are used, the maximum length shall not

exceed 36 in. (915 mm).

3. When lever handle type manual equipment shutoff valves are

used, they shall be T-handle valves.

4. The use of copper tubing for gas piping is NOT approved by the

State of Massachusetts.

Loading...

Loading...