6

BACK GAUGE ADJUSTMENT

Slide back gauge rods (62) through the adjustment blocks (66) and brackets (71). Mount the rods in the holes

found at the rear of the cutter bar. Move the gauge angle (63) up the rods until it contacts with the lower blade.

Observe the pointers attached to the adjustment blocks and adjust the rods in or out until the embossed scales read

zero on the pointers. Tighten the set screws (44) to lock the rods in place.

To attain a particular setting, loosen the four lock screws (70) and slide the gauge to an approximate position. Fine

tune adjustments are accomplished by locking the screws of the two adjustment brackets (71) while keeping those

of the blocks (66) loose. The adjustment dial (68) can then be used to position the gauge in or out.

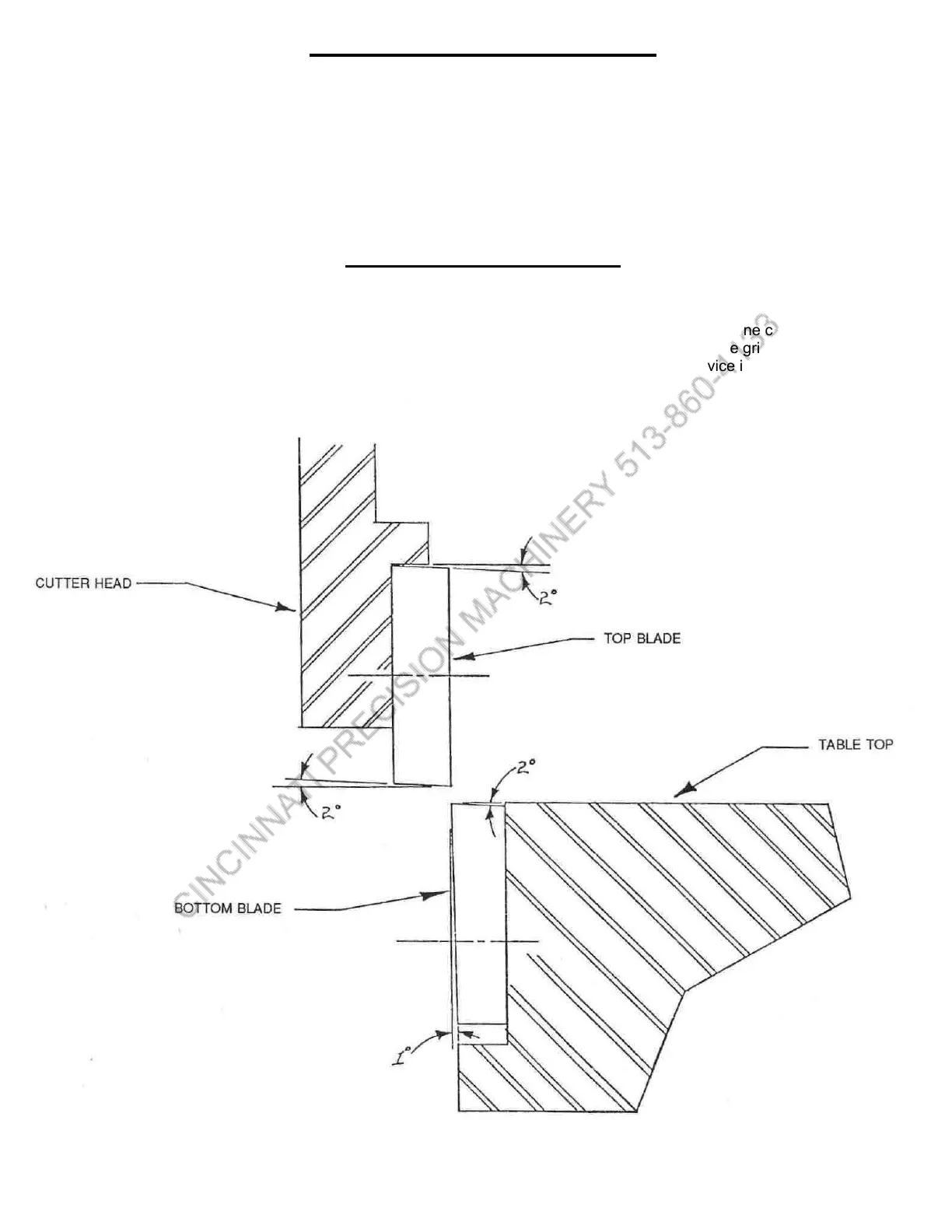

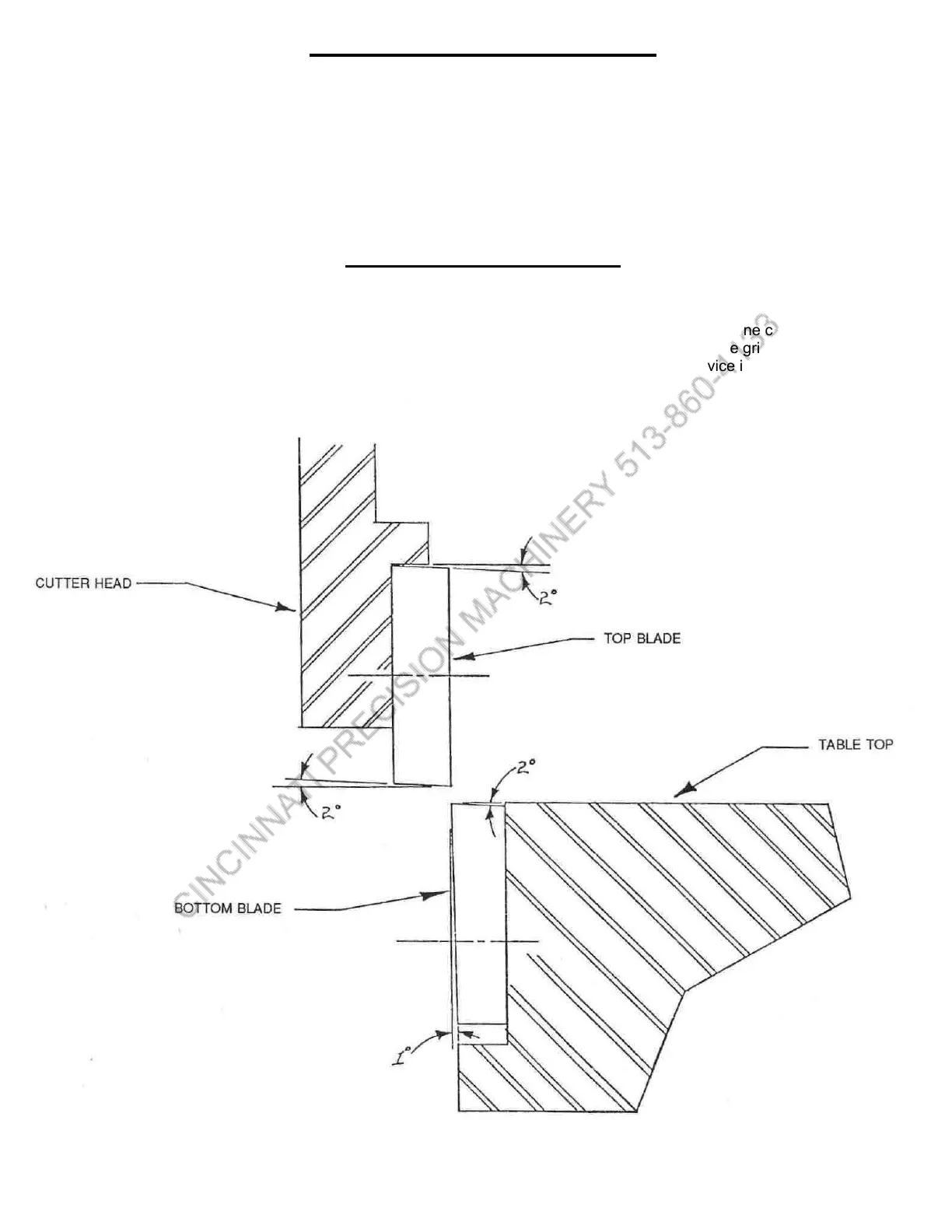

SHARPENING BLADES

Your TENNSMITH shear features “Tri-Action” ground blades. The upper blade has two cutting edges which are

ground with a 2 degree edge relief. The upper blade can be turned over to expose the new cutting edge. It can be

sharpened on a surface grinder by grinding both wide sides to the blade. The lower blade has one cutting edge

with a 2 degree cutting edge relief and a 1 degree face relief. It can be sharpened on a surface grinder by grinding

the wide side of the blade having the 1 degree relief. See Figure 2). Blade sharpening service is available from the

factory.

Loading...

Loading...